17

MAN 9064762 EN V1

P. Lindberg A/S

Sdr. Ringvej 1

www.p-lindberg.dk

Tel.: 70212626

DK-6600 Vejen

e-mail: [email protected]

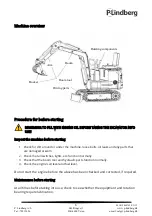

Inspection of the hydraulic oil system

CAUTION: The hydraulic system can become very warm during use. Ensure

that the machine has cooled down before carrying out inspection and

maintenance.

1.

Ensure that the machine is positioned on a level and stable surface.

2.

Lower the bucket to the ground and switch off the engine.

3.

Do not begin the maintenance tasks until the systems, hydraulic oil and lubricant agent

have completely cooled down, since the hydraulic system can still be warm and under

pressure immediately after the work has ceased.

a)

Empty air from the hydraulic oil tank to release the interior pressure.

b)

Let the machine cool down.

CAUTION: The inspection of maintenance of hot parts and pressurised parts

can lead to the ejection of pressurised hydraulic oil which can cause personal

injury.

c)

When removing nuts and bolts, do not have your body facing the nuts and bolts

as hydraulic parts are still under pressure even though they have cooled down.

d)

Never check parts that can move or rotary parts or the engine circuit while the

machine is on an incline, as there can be pressure from their own weight.

4.

Ensure the gasket surface is free of dirt and damage when connecting hydraulic hoses

and piping. Remember:

a)

Clean hoses, piping and the inside of the hydraulic oil tank using a suitable

cleaning agent and allow them to dry completely.

b)

Use O-rings that are free of damage and defects.

c)

When connecting the pressure hose, it must not be turned as this will shorten

its lifetime.

d)

Secure carefully using the low pressure hose clamp.

5.

The hydraulic oil that is added must be of the same quality (HLP 46). Do not mix oils

that have a different quality. The machine is supplied filled with hydraulic oil. Therefore

only use the recommended oil. All oil in the system must be replaced at the same time.

6.

Never start the engine without hydraulic oil.