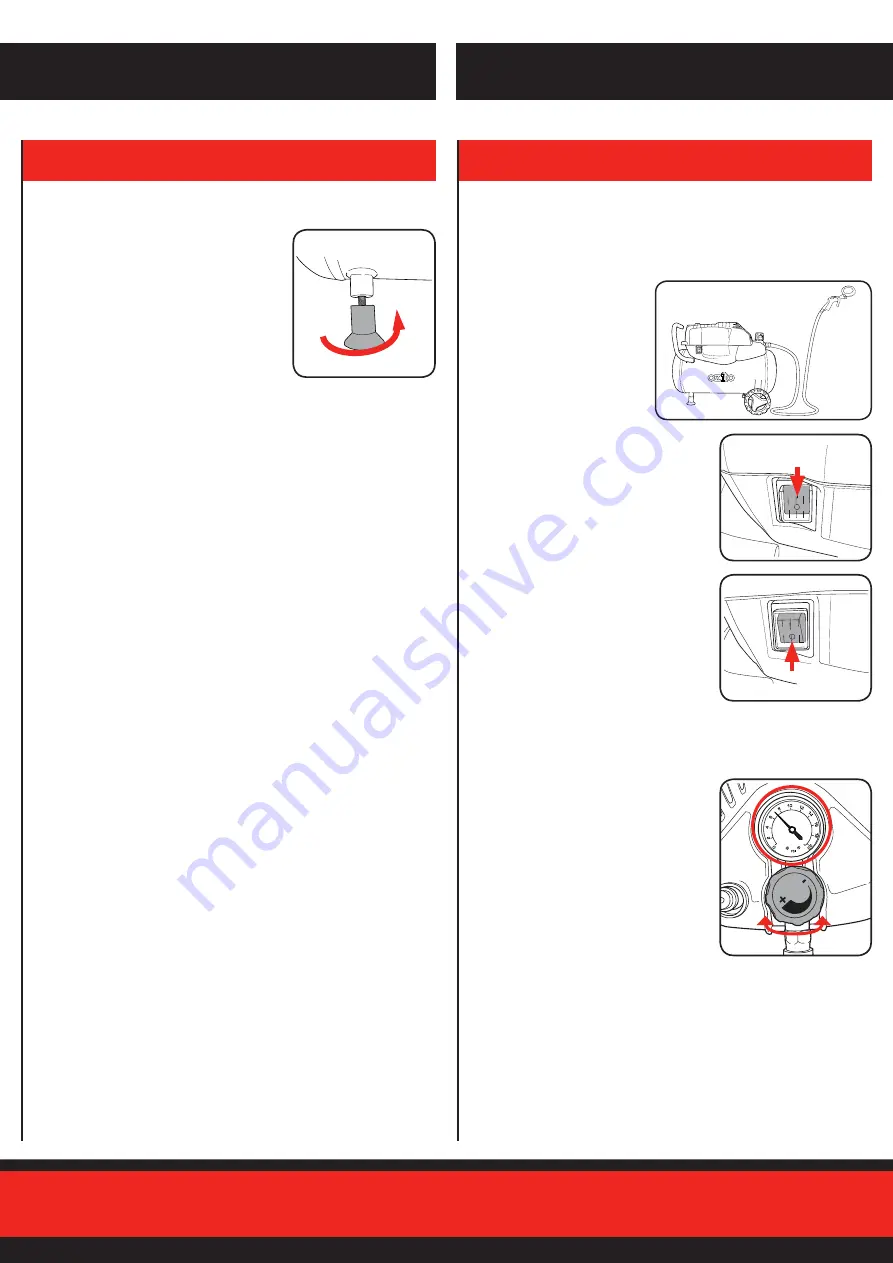

Fitting the supporting foot

1. Screw the supporting foot in the

supporting foot bracket.

Switching On/Off

Note:

It is recommended that the power supply is protected by a

Residual Current Device (RCD) of rating not exceeding 30mA.

1. Attach the desired tool

to the quick release air

outlet.

2. To switch the compressor On, set the

On/Off switch to position “I” (On).

3. To switch the compressor Off,

move the On/Off switch to position

“O” (Off).

Adjusting the pressure

Once set up and On you can adjust the

air pressure by turning the pressure

regulating knob.

1. To increase the air pressure, rotate

the regulating knob clockwise. To

decrease the pressure, rotate the

regulating knob anti-clockwise.

Note

:

Air must be flowing through the

quick release air outlet, and the attached

air tool in order to obtain the correct output reading on the pressure

gauge.

2. OPERATION

OPERATION