1

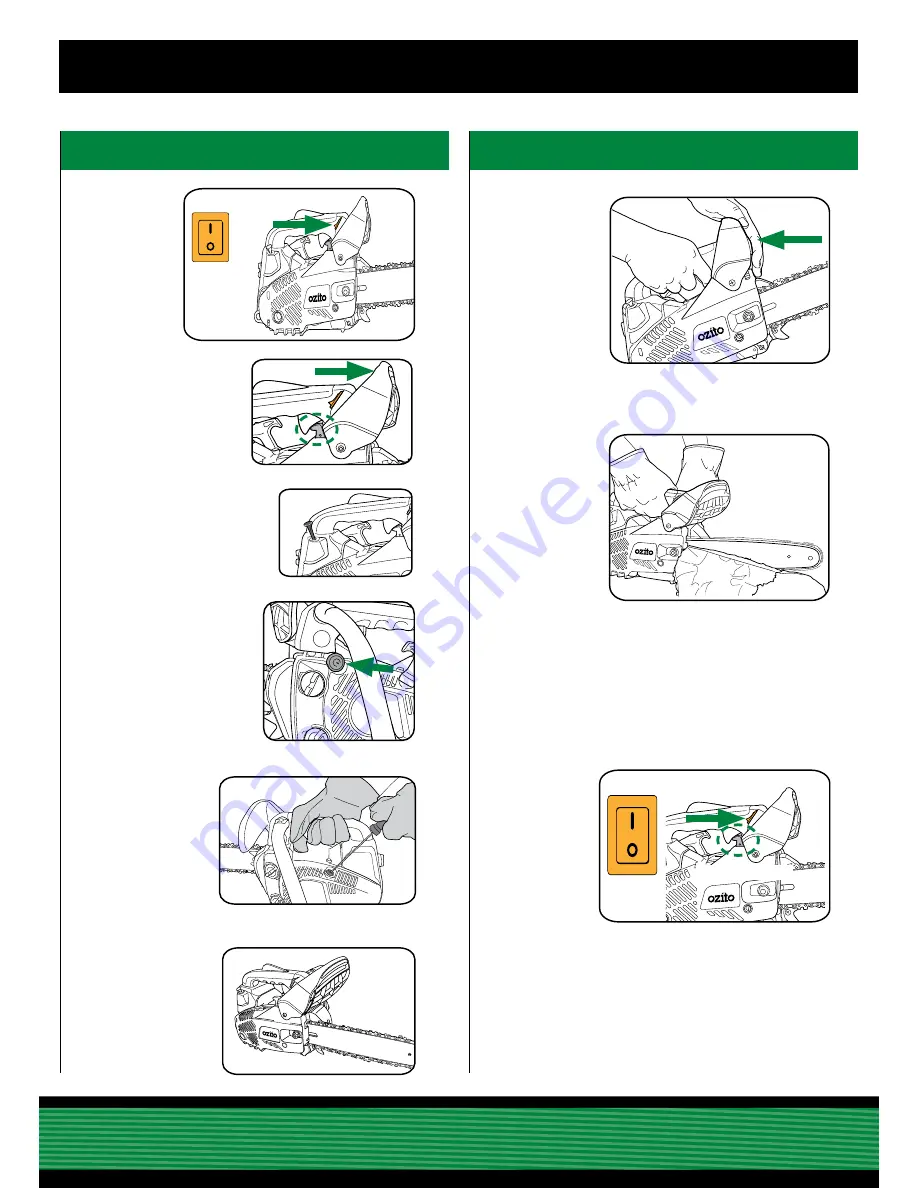

4. COLD STARTING

5. CUTTING

1. Set the

switch to ON “I”.

3. Pull the choke (fully withdrawn).

4. Depress the priming bulb

approximately 6 times until the

bulb is full.

5. Hold the chainsaw

securely on the

ground. Pull the recoil

starter until “kicks”

(attempts to start),then

depress throttle trigger

to release choke to

RUN position. Pull the

recoil starter several

times until started.

6. Allow the engine

to warm up for 10

seconds.

1. When ready to start cutting, release the brake, by pulling the

front guard back firmly towards the rear of the chainsaw

Stopping the chainsaw

“I” ON

2. The chainsaw has bucking spikes to assist with cutting and

reduce the chance of kickback, use them as follows. Keep the

bucking spikes touching the wood you are cutting. Due to the

rotation of the chain, it will pull the saw into the wood. When the

bucking spikes are touching the timber, it will help prevent any

sudden jerking or kick-back.

“O” OFF

Brake Engaged

2. Make sure the brake

is ON when starting for

safety, by pushing the front

guard forward

3. Engage brake and set the On/Off switch to OFF “O”.