Form No. OVmm-0113

10

OPERATION

Programming Menu Items

Use the following procedure to edit or create menu items. This

procedure requires access to password-protected screens and

should be performed by authorized personnel only.

NOTE: The USB port allows the uploading of pre-programmed

menu items from an external USB drive. Refer to the

“Uploading from a USB Drive” procedure in this section

for details.

1. From the main menu screen on either touchscreen, touch

the BaCK arrow.

• a password keypad will appear on the touchscreen.

2. Input the password using the keypad, and touch ENTER.

• The Home screen will appear on the touchscreen.

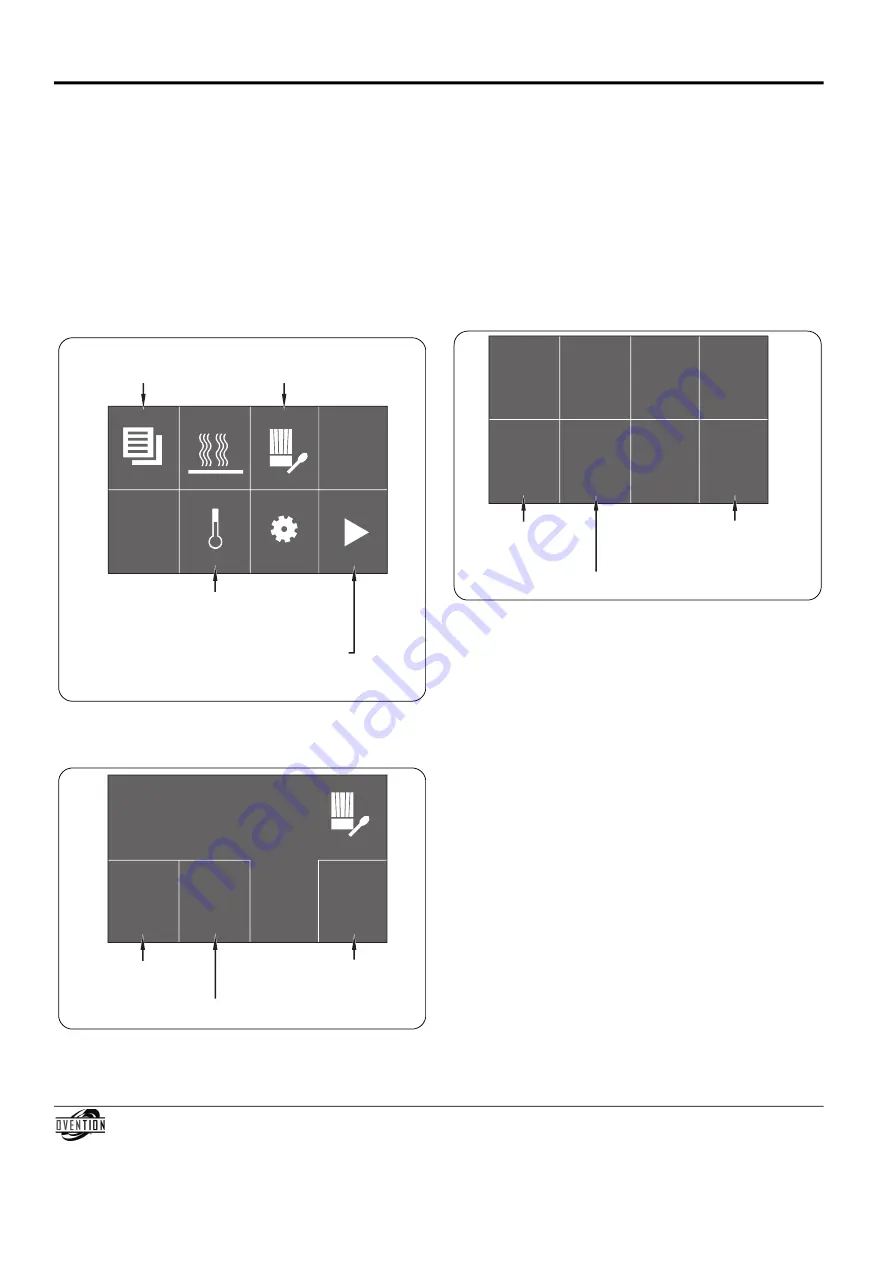

Home Screen

3. Touch the chef’s hat/spoon icon to access the menu

Development screen.

menu Development Screen

Touch to return to

Main Menu screen.

Touch to access

Setpoint Temperature screen

shown at startup.

Touch to access

Menu Development

screen.

Touch arrow to move slider assembly from

left-to-right (right touchscreen shown).

Arrow will appear in opposite corner on left

touchscreen to move slider from right-to-left.

Menu Development

New

Edit

Back

Touch to edit an

existing menu item.

Touch to create

a new menu item.

Touch to return to

Settings screen.

4. Touch either NEW or EDIT to create or edit a menu item.

• a screen that looks like the main menu screen will appear.

• If creating a new menu item, touch an empty box, and

the menu Item Settings screen will appear. If no empty

boxes are available, touch the “down” arrow in the

bottom right box to scroll to the next main menu screen.

If creating a new menu item in an existing Category,

touch the Category, then touch an empty box in the

Category menu screen.

• If editing an existing menu item, touch the desired menu

item, and the menu Item Settings screen will appear. If

editing a menu item in an existing Category, touch the

Category, then touch the desired menu item in the

Category menu screen.

menu Item Settings Screen

5. Touch each “setting” box on the menu Item Settings screen

to edit the corresponding setting. Settings include item

name, cook time, top blower percentage, bottom blower

percentage, cook temperature, and number of stages.

• Touching a “setting” box will bring up a keypad specific

to the setting. Enter the desired value using the keypad,

then touch ENTER to return to the menu Item Settings

screen.

• menu item names can have up to 16 characters.

• Each menu item can be programmed to have up to

three stages, depending on the food product. Stages are

programmed with unique settings to create a

customized cooking sequence for the menu item.

NOTE: It is not necessary to create stages for a menu item if it

is not required by the food product. If unique stages are

not required, leave the cook time setting for stages 2

and 3 at zero.

• To delete a menu item, change the item name to

DELETE (all caps) and touch ENTER to return to the

menu Item Settings screen. Touch BaCK/SaVE on the

menu Item Settings screen to confirm deletion.

6. When the menu item settings are complete, touch

BaCK/SaVE to save settings and return to the menu

Development screen.

• To continue programming, repeat steps 4 and 5 of this

procedure.

• If programming is complete, touch BaCK on the menu

Development screen to return the Home screen.

Start

Cookies

Back/

Save

Bottom

Blower

50%

Stage 1/3

(next)

Top

Blower

50%

Temp

500 F

Time

1:00

Touch to save settings and return

to Menu Development screen.

Touch to start

the menu item

cooking sequence.

Touch to access settings

for next stage.

Total Restaurant Supply - https://totalsupply1.com - Toll Free 1-800-944-9304 - Local 507-288-9454

2940 Hwy 14 W, Rochester, MN 55901