SECTION 4 - BOOM & PLATFORM

3121623

– JLG Lift –

4-11

Three month inspection

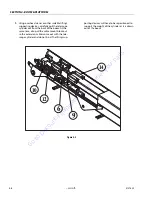

1.

Remove all protection sumps from the third arm

and the two extensions. Use a flashlight torch to

visually check the state of the ropes and the

extension pulleys.

2.

Check the correct rope tension, trying to bend

them manually. If they are pulled correctly they

should not be able to move more than a few mil-

limeters.

3.

Check that in the extension arms exit phase the

return ropes are sufficiently in traction in a way

not to allow relative contact with the third arm.

4.

Vice versa in the extension return phase, check

that the outlet ropes are subject to a tension that

allows them not to come into contact with the

second extension or the cylinder.

5.

Use a torque wrench to check the correct torque

of al rope fixing nuts and the respective rocker

arms; recommended torque 10 Nm.

If the tension of the ropes should not be adequate the

conditions for use must be restored by scrupulously fol-

lowing the Ropes Tension Adjustment procedure reported

following.

4.4

WIRE ROPE TENSION ADJUSTMENT PROCEDURE

NOTE:

Do not clamp on threads.

Figure 4-19. Clamping Wire Ropes

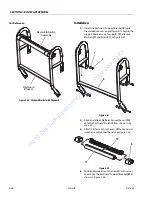

1.

Loosen the register counter-nuts by a few turns,

position them in a way to access the adjustment

nuts in order to make the adjustment. (two nuts

with relative counter-nut for extend ropes and

one nut with relative counter-nut for retract

ropes rocker arm).

2.

Completely retract both extendible arms and

make them escape for about 30-40cm.

3.

Tighten the nut for the traction of the fixing

rocker arm of the return ropes to a torque of

10Nm.

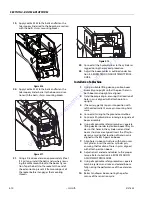

Figure 4-20. Return ropes fixing rocker arm

4.

Completely extend the extensions and retract

them by about 30-40cm.

5.

Tighten the bolts of the two output cables so

that the threaded terminals come out of 65±3

mm from the rocker arm. During adjustment

Go

to

Discount-Equipment.com

to

order

your

parts