SECTION 4 - BOOM & PLATFORM

3121623

– JLG Lift –

4-1

SECTION 4. BOOM & PLATFORM

4.1

BOOM MAINTENANCE

NOTICE

IF PERFORMING MAINTENANCE ON THE BOOM, DO NOT USE A LIFTING

DEVICE TO LIFT THE BOOMS UNLESS THE HOLDING VALVES HAVE BEEN

REMOVED FIRST. FAILURE TO DO SO WILL RESULT IN SEVERE DAMAGE

TO THE BOOM.

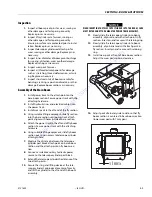

Removal of the Boom Assembly

1.

Remove the platform and platform support as

follows:

a.

Disconnect electrical cable from control

console.

b.

Tag and disconnect the hydraulic lines run-

ning to the rotate cylinders. Cap the hydrau-

lic lines and ports.

c.

Using an overhead crane or suitable lifting

device, use nylon support straps to support

the platform/support.

NOTE:

When removing the retaining pin from the rod end

of the level cylinder, make sure the cylinder is prop-

erly supported.

d.

Remove bolts and keeper pins that secures

the retaining pins. Using a suitable brass

drift and hammer, remove the retaining pins

from the platform support.

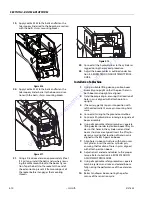

2.

Remove the boom from the turntable as follows:

a.

Disconnect wiring harness from ground

control harness connector.

NOTICE

HYDRAULIC LINES AND PORTS SHOULD BE CAPPED IMMEDIATELY

AFTER DISCONNECTING LINES TO AVOID ENTRY OF CONTAMINANTS

INTO SYSTEM.

b.

Tag and disconnect hydraulic lines from

boom to control valve. Use a suitable con-

tainer to retain any residual hydraulic fluid.

Cap all hydraulic lines and ports.

c.

Using a suitable lifting equipment, ade-

quately support boom weight along entire

length.

d.

Remove the bolts and keeper pins securing

the lift cylinder pivot pin. Using a suitable

brass drift and hammer, remove the pivot

pin from the lower boom.

e.

Remove hardware securing the level link

pivot pin. Using a suitable brass drift and

hammer, remove the pin from the level link

and turntable.

f.

Remove hardware securing the lower boom

pivot pin. Using a suitable brass drift and

hammer, remove pin from the turntable.

g.

Using all applicable safety precautions, care-

fully lift boom assembly clear of turntable

and lower to ground or suitable supported

work surface.

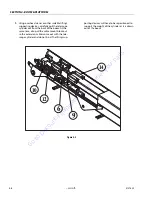

Disassembly of the Main Boom

1.

Loosen jam nuts on aft end of fly boom wear pad

adjustment and loosen adjustments.

2.

Using a portable power source, attach hose to

telescope cylinder port block. Using all applica-

ble safety precautions, activate hydraulic system

and extend cylinder to gain access to cylinder

rod retaining pin. Shut down hydraulic system.

3.

Carefully disconnect hydraulic hose from retract

port of cylinder. There will be initial weeping of

hydraulic fluid which can be caught in a suitable

container. After initial discharge, there should be

no further leakage from the retract port.

4.

Remove hardware securing telescope cylinder to

the fly boom section, then remove pin from fly.

5.

Remove hardware securing telescope cylinder to

the base boom section.

NOTICE

WHEN REMOVING TELESCOPE CYLINDER FROM BOOM SECTIONS.

CARE SHOULD BE TAKEN NOT TO LEAVE CYLINDER REST ON POW-

ERTRACK WHICH COULD CAUSE DAMAGE TO POWERTRACK.

6.

Using a suitable lifting device, remove telescope

cylinder from boom sections.

7.

Using a piece of tape, mark the length of hoses

and wires from front of fly boom and bottom of

base boom for reassembly.

8.

Remove hardware securing the front wear pads

on base boom section, remove wear pads.

9.

Remove hardware securing the powertrack to

the aft end of the fly boom section.

10.

Using a suitable lifting device, remove fly boom

from boom section.

11.

Remove hydraulic lines and electrical cables

from powertrack.

12.

Remove hardware securing powertrack to the

base boom section. Remove powertrack.

Go to

Discount-Equipment.com

to

order your

parts