SECTION 6 - GENERAL SPECIFICATIONS AND OPERATOR MAINTENANCE

6-22

– JLG Lift –

3121132

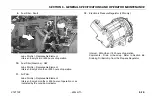

Tighten the lug nuts to the proper torque to prevent wheels from

coming loose. Use a torque wrench to tighten the fasteners. If

you do not have a torque wrench, tighten the fasteners with a

lug wrench, then immediately have a service garage or dealer

tighten the lug nuts to the proper torque. Over-tightening will

result in breaking the studs or permanently deforming the

mounting stud holes in the wheels. The proper procedure for

attaching wheels is as follows:

1.

Start all nuts by hand to prevent cross threading. DO

NOT use a lubricant on threads or nuts.

2.

Tighten nuts in the following sequence:.

3.

The tightening of the nuts should be done in stages. Fol-

lowing the recommended sequence, tighten the nuts

per wheel torque chart.

Wheel nuts should be torqued after the first 50 hours of oper-

ation and after each wheel removal. Check torque every 3

months or 150 hours of operation.

6.6 DRAINING OIL BUILD UP FROM THE

PROPANE REGULATOR

During the course of normal operation, oils may build inside

the primary and secondary chambers of the propane pres-

sure regulator. These oils may be a result of poor fuel quality,

contamination of the fuel supply chain, or regional variation

in the make up of the fuel. If the build up of the oil is signifi-

cant this can effect the operation of the fuel control system.

Refer to Section 6.4, Operator Maintenance, for maintenance

intervals. More frequent draining may be required if the fuel

supply has been contaminated.

1

2

3

4

5

6

7

9

8

9 LUG PATTERN

Table 6-11. Wheel Torque Chart

TORQUE SEQUENCE

1st Stage

2nd Stage

3rd Stage

40-50 ft lbs

(60-70 Nm)

90-105 ft lbs

(125-150 Nm)

145-170 ft lbs

(200-240 Nm)