Installation

−

11

−

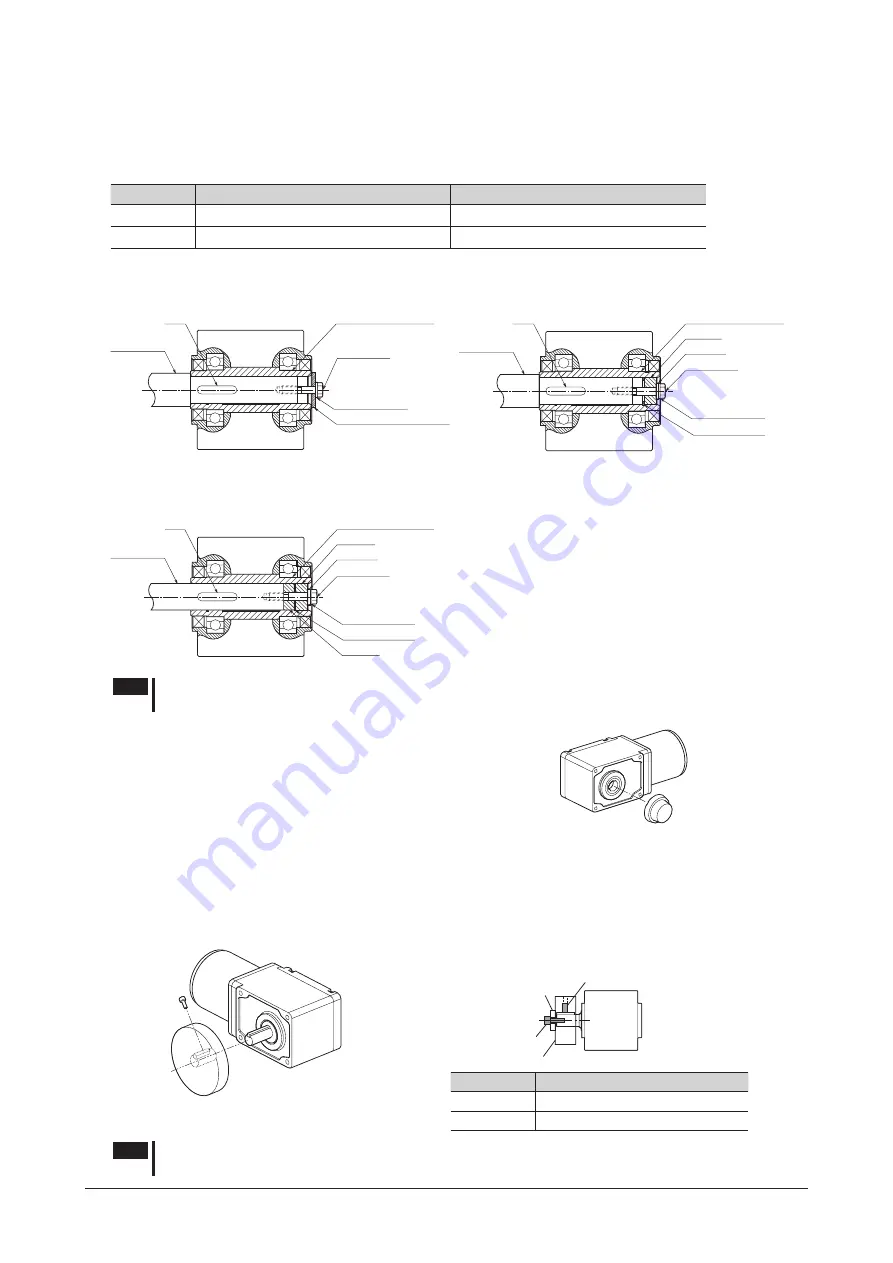

Right angle • hollow shaft type

Mounting method of the load varies depending on the load shaft conditions. See the following figures.

The hollow output shaft inside dimension is processed to a tolerance of H8, and incorporates a key slot for load shaft attachment.

A load shaft tolerance of h7 is recommended.

Apply grease on the surface of the load shaft and inner walls of the hollow output shaft to prevent seizure.

Motor model

Hollow shaft inside dimensions (H8)

Recommended load shaft dimensions (h7)

SCM4

Ø18

+0.027

0

mm (Ø0.7087

+0.0011

0

in.)

Ø18

0

-0.018

mm (Ø0.7087

0

-0.0007

in.)

SCM5

Ø25

+0.033

0

mm (Ø0.9843

+0.0013

0

in.)

Ø25

0

-0.021

mm (Ø0.9843

0

-0.0008

in.)

•

Stepped load shaft

Mounting method using end plate

Hollow output shaft

End plate

SCM4

: Plate thickness

3 mm (0.12 in.)

SCM5

: Plate thickness

4 mm (0.16 in.)

Key

Load shaft

Screw

SCM4

: M5

SCM5

: M6

Spring washer

Mounting method using retaining ring

Hollow output shaft

Spacer

Washer

Screw

SCM4

: M5

SCM5

: M6

Spring washer

Retaining ring

Key

Load shaft

•

Non-stepped load shaft

Hollow output shaft

Spacer

Washer

Spring washer

Retaining ring

Spacer

Key

Load shaft

Screw

SCM4

: M5

SCM5

: M6

Note

Do not apply excessive or abrupt force to the hollow output shaft when inserting a load shaft into the

hollow output shaft. Excessive or abrupt force may damage the gearhead internal bearings.

•

Installing the safety cover

After installing the load, attach the safety cover.

When removing the safety cover, insert a plastic stick with a flat tip to the

cutout of the safety cover, and remove.

Safety cover

(Included)

Right angle • solid shaft type

The shaft of the gearhead has been machined to an outer diameter tolerance of h7 and is provided with a key slot for connecting

the transmission parts. When connecting the transmission parts, ensure that the shaft and parts have a clearance fit, and always

fix the parallel key to the output shaft with a screw to prevent the parts from rattling or spinning. With the solid shaft type,

use a tapped hole provided at the end of the output shaft as an auxiliary means for preventing the transfer mechanism from

disengaging.

Fixed screw

Transmission parts

Fixed screw

Screw

Spacer

Transmission parts

•

Example of using the output shaft end tapped hole

Motor model

Output shaft end tapped hole

SCM4

M5 Effective depth 10 mm (0.39 in.)

SCM5

M6 Effective depth 12 mm (0.47 in.)

Note

Do not apply excessive force onto the output shaft of the gearhead using a hammer or other tools. Doing

so may cause damage to the output shaft or bearings.