Connection

−13−

5.2 Connecting the motor

Connect the motor connector (white) of the motor cable to the CN2, and the sensor connector (black) to the CN3 on

the driver. Check the pin assignment on p.38.

Use a connection cable (supplied or accessory) when extending the wiring distance between the motor and driver.

The connection cable can be connected up to 2 pieces. The wiring distance between the motor and driver can be

extended to a maximum of 10.5 m (34.4 ft.).

Note

Ensure that the connector plugged in securely. Insecure connections may cause malfunction or

damage to the motor or driver.

5.3 Grounding

Be sure to ground the product.

Ground the motor and driver using the Protective Earth Terminal (PE) respectively.

Note

Ground the product securely. Failure to do so may result in electric shock or damage to the

product.

The product will tend to be electrified especially in a dry environment, so it may be damaged by

static electricity.

Motor

Connect the Protective Earth Terminal (PE) on the motor to the ground near the motor.

Minimize the wiring length of the ground cable.

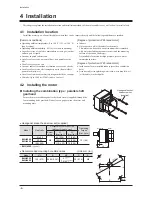

Ground terminal

PE

•

Applicable crimp terminal:

Round crimp terminal with insulation cover

•

Thread size of terminal: M4

•

Tightening torque: 1.2 N·m (10.6 lb-in)

•

Applicable lead wire: AWG18 to 14 (0.75 to 2.0 mm

2

)

4.8 (0.19) or less

9.5 (0.37) or less

Ø4.1 (0.16) or more

[Unit: mm (in.)]

Driver

Two Protective Earth Terminals (PE) are provided on the driver. Ground either of the two Protective Earth Terminals

near the driver. You can ground either of the two Protective Earth Terminals. The terminal that is not grounded is used

as a service terminal. Use the service terminal according to your specific

need, such as connecting it to the motor in order to ground the motor.

Do not share the Protective Earth Terminal with a welder or any other

power equipment.

Ground terminal

•

Applicable crimp terminal:

Round crimp terminal with insulation cover

•

Thread size of terminal: M4

•

Tightening torque: 1.2 N·m (10.6 lb-in)

•

Applicable lead wire: AWG18 to 14 (0.75 to 2.0 mm

2

)

PE

Ground one of

these terminals.

5.4 Connecting the I/O signals

Connect the I/O signals to CN4 on the driver. Refer to p.16 for connection examples with a programmable controller.

Connecting the lead wire

Connect to insert the lead wire to the connector.

•

Applicable lead wire: AWG24 to 18 (0.2 to 0.75 mm

2

)

•

Length of the insulation cover which can be peeled: 10 mm (0.39 in.)

Crimp terminals can also be used to connect.

If crimp terminals are used, select the following terminals.

Manufacturer: PHOENIX CONTACT GmbH & Co. KG

Model

:

AI 0,25-10 [Conductor cross-sectional area: 0.14 to 0.34 mm

2

(AWG24)]

AI 0,34-10 [Conductor cross-sectional area: 0.14 to 0.34 mm

2

(AWG22)]

AI 0,5-10 [Conductor cross-sectional area: 0.40 to 0.65 mm

2

(AWG20)]

AI 0,75-10 [Conductor cross-sectional area: 0.65 to 0.82 mm

2

(AWG18)]

Connector model: DFMC1,5/6-ST-3,5

(

PHOENIX CONTACT GmbH & Co. KG

)

Summary of Contents for BMU5200A Series

Page 43: ...43...