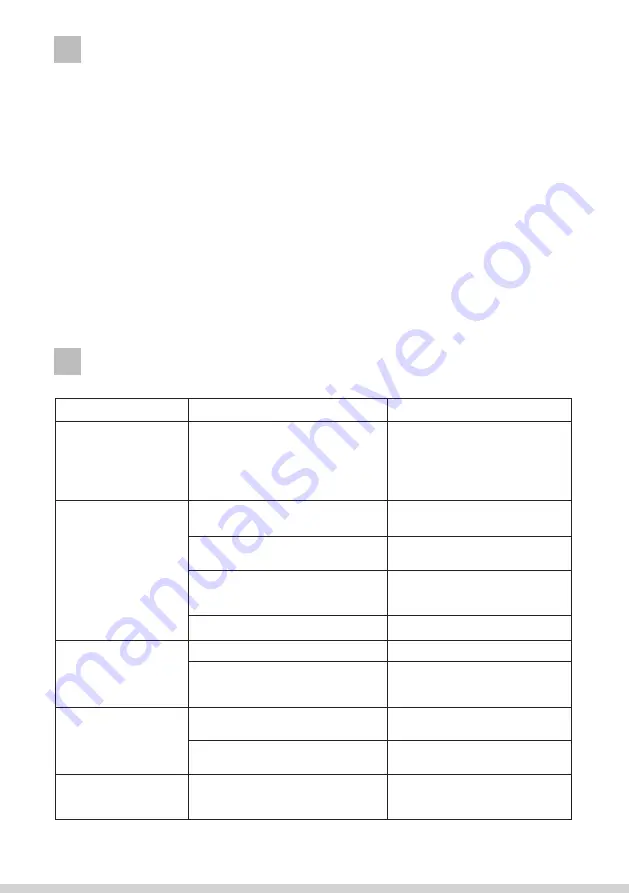

SYMPTOM

CAUSE

POSSIBLE SOLLUTION

Equipment will not

turn on.

1. Power not plugged in.n.

2. Power switch is “off”.

3. Fuse gone.

4. Blown main power fuse gone.

1.Plug the power cord into ap-

propriate socket.

2. Switch on the power

3. Reset the fuse.

4. Replace the fuse.

There is power, but

the rollers are not

running after the hot

button is pressed:

1. Emergency switch is engaged.

1. Disengage the emergency

switch.

2. Safety cover is not closed.

2. Close the safety cover to

active the safety switch.

3. Guide table is not installed

correctly.

3. Properly install the paper

guide so that the micro switch

is activated.

4. Blown motor fuse.

4.Replace the motor fuse.

The unit is not

heating up.

1. The machine is in “COLD” mode.

1. Switch to “HOT” mode.

2. Set temperature is lower than

the room temperature.

2. Rasie the temperature

according to the recommended

film temperature.

Curled lamination.

a. Upward curl.

a. Loosen the top roll film

tension.

b. Downward curl.

b. Loosend the bottom roll film

tension.

Unclear lamination.

a. The main roller temperatures

are too low and lamination speed

is too fast.

a. Raise the roller

temperatures and lower the

lamination speed.

10 MAINTENANCE

Open the rollers with the tension handle when not laminate for a long time. This will prevent

the device from overheating. Remember to turn off after use. Working with one roll of laminating

film or when the top and bottom rollers are not in the right position can leave the adhesive on

the rollers which will affect the next lamination. Adjust the film tension appropriately using the

tensioning handle. If the tension is too strong, the film may stretch.

While laminating a bit of adhesion may come out on to the rollers, it should be removed

regularly.

• Do not clean the rollers when moving.

• Use only soft cleaning cloths and purer alcohol or methylated spirit. DO NOT use petroleum

based products.

• Do not leave the rollers under pressure when not working, put in standby mode for longer life.

• Alway keep the rollers clean for best results.

18

11 TROUBLE SHOOTING

Summary of Contents for RolLAM 380 Super

Page 10: ...10...