4.

The

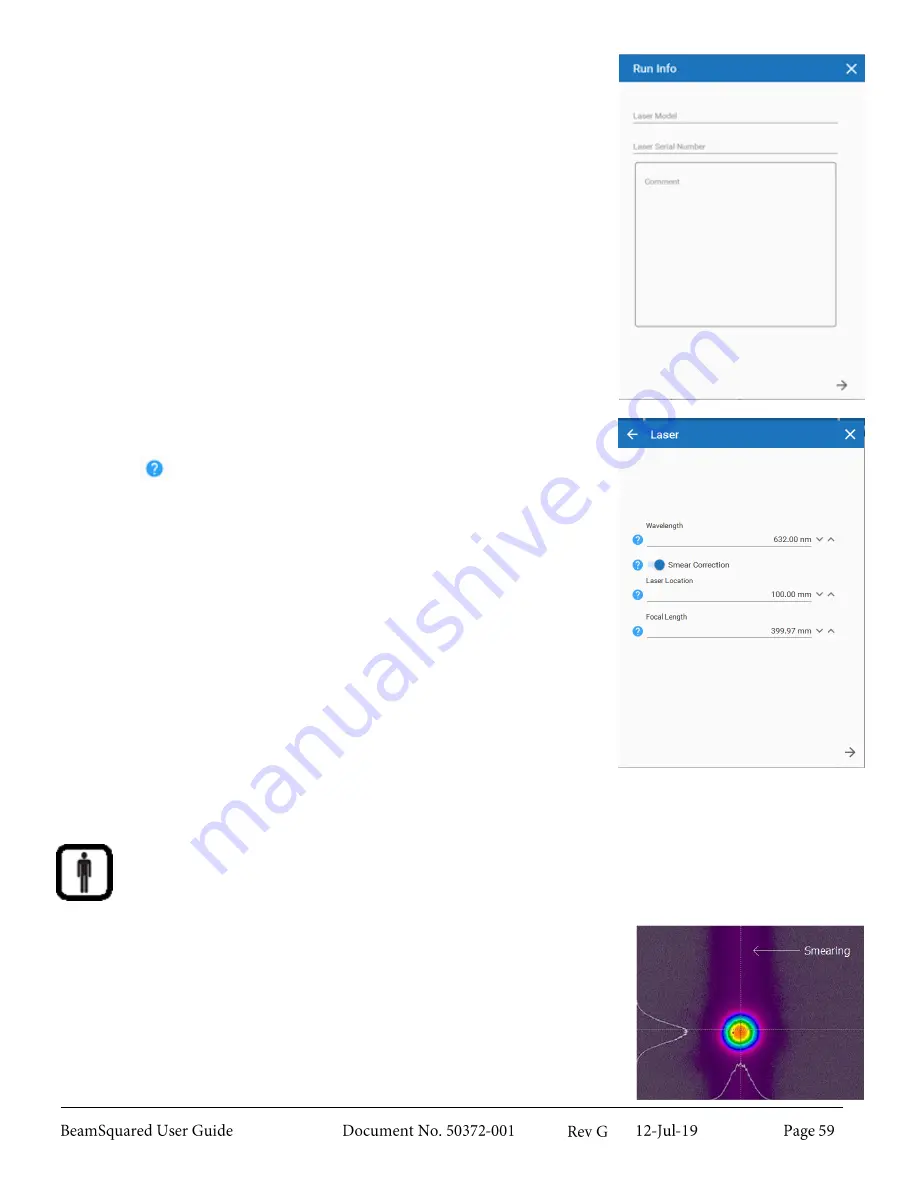

Run Info

screen that appears is optional. Values entered are

included on the report. Select the arrow at the bottom of the

window to continue.

5.

The

Laser

screen prompts you to enter information on the laser.

These values must be correct to obtain accurate results. Hover over

the

to get a description about each entry. This information

must be entered for each laser under analysis. Once entered select

the arrow to continue.

a.

Enter the

Wavelength

to get accurate measurements.

b.

If you encounter smearing* in the image turn on

Smear

Correction

.

c.

Enter a value of zero for the

Laser Location

to locate the

waist relative to the BeamSquared reference datum (the

input aperture on the red BeamSquared case for automatic

mode or the lens for manual mode). To locate the waist

relative to the laser, enter the distance from the

BeamSquared reference datum to the laser faceplate.

d.

The Automated BeamSquared system collects the Focal

Length from the lens cassette RFID feature and

automatically corrects the value based on the entered

wavelength.

Enter the

Focal Length

of the lens used to create the artificial beam waist in millimeters.

* Smearing manifests as a streak along the vertical axis of the camera. It is

caused by an excessive amount of incident power on the sensor, typically as

a result of a poor match between the laser wavelength and the camera

sensor’s quantum efficiency. Silicon-based sensors have high quantum

efficiency at visible wavelengths, and InGaAs sensors are most efficient in the

NIR and IR range. Therefore, silicon sensors tend to experience smearing in

the NIR and IR ranges while InGaAs sensors experience it in the visible.

Summary of Contents for BeamSquared

Page 10: ......

Page 15: ...BeamSquared Optical Train Dimensions 1 4 ...

Page 75: ...400mm Focal Length Lens M2 1 500mm Focal Length Lens M2 1 ...

Page 87: ......