35

6.2.

Switching Scenes on the Vision Sensor

For a processing to switch scenes on the Vision Sensor, follow the procedures below.

1

Set a scene number for the switching destination to a variable.

'(1) Change the scene of the FH

' You have to select a scene No. for your application.

fh_sceneno_input = 0

2

Set the variables as arguments to the scene switching command execution

sample function (fhsample_chgscn) to the Vision Sensor and execute it.

CallProc fhsample_chgscn(fh_sceneno_input)

'Error check

If fh_err_number <> fh_success

GoTo *CLOSE_SAMPLE

ENDIF

6.3.

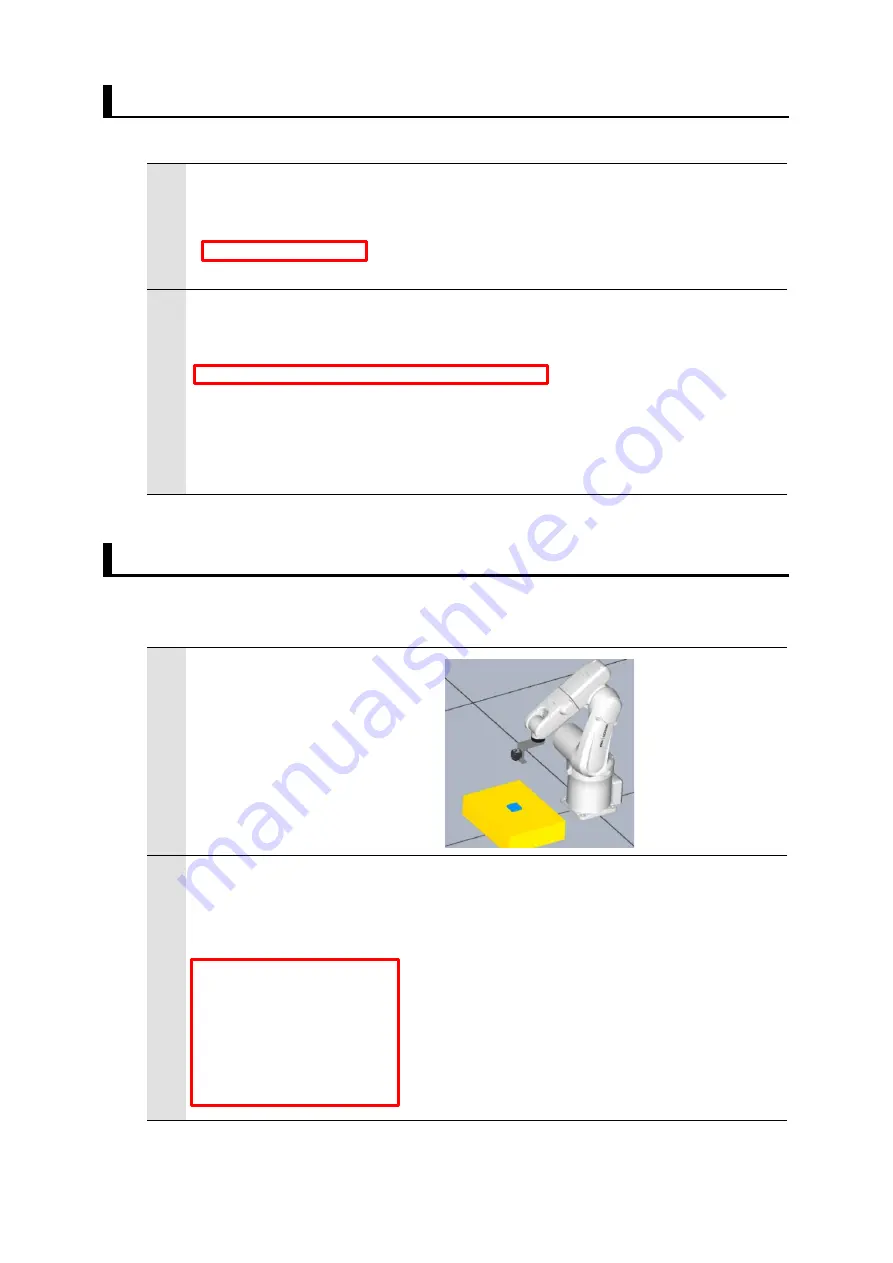

Moving Robot to Robot Image Position

For a processing to move the robot to the robot image position, follow the procedures

below.

1

Move the robot to the imaging

position.

Check the current robot

position (Precautions unit of

the Rotation Vector).

2

Set the referenced imaging position to the variables.

'(2) Move the robot to the imaging position

' You have to configure the following robot position for your application.

fh_move_position[1] = 0 'std_img_pos_x

fh_move_position[2] = -240 'std_img_pos_y

fh_move_position[3] = 600 'std_img_pos_z

fh_move_position[4] = -180 'std_img_pos_w

fh_move_position[5] = 0 'std_img_pos_p

fh_move_position[6] = 90 'std_img_pos_r

Scene number

Scene switching command execution sample function

Set the robot imaging position to the variables.