FZ5-110

□

FZ5-110

□

-10

FZ5-60

□

FZ5-60

□

-10

2013

Precautions for Correct Use

●Installation and Storage Sites

Install and store the product in a location that meets

the following conditions:

•Surrounding temperature of 0 to +50°C(-20 to + 65°C in storage)

• No rapid changes in temperature (place where dew does not form)

• Relative humidity of between 35 to 85 %

• No presence of corrosive or flammable gases

• Place free of dust, salts and iron particles

• Place free of vibration and shock

• Place out of direct sunlight

• Place where it will not come into contact with water, oils or chemicals

●Orientation of Product

To improve heat dissipation, install the product in the

following orientation only

.

The main body must be installed so as not to block the vent.

This product contains a lithium battery for which the following notice applies :Perchlorate Material - special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

■

U.S. California Notice:

■

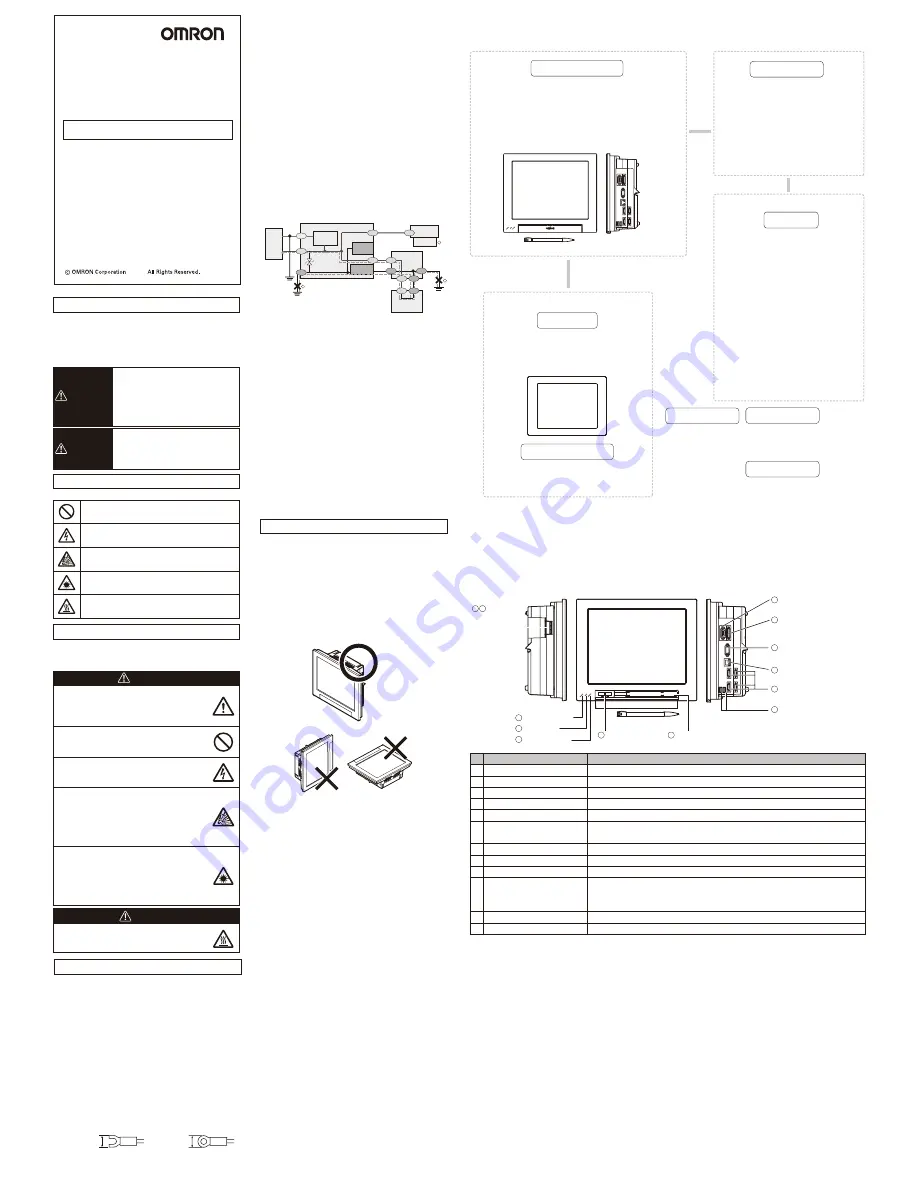

Confirming Package Contents

■

Basic Configuration

*

Camera 4ch type

FZ5-110

□

-10

FZ5-60

□

-10

Do not install in this orientation.

Camera 2ch type

FZ5-110

□

FZ5-60

□

Camera 4ch type

FZ5-110

□

-10

FZ5-60

□

-10

Camera 2ch type

FZ5-110

□

FZ5-60

□

●Ambient Temperature

• Maintain a minimum clearance of 50 mm above and below the controller

to improve air circulation. A minimum clearance of 10 mm between

other devices must also be maintained on the right and left sides of the

product. However, if the adjacent devices do not generate heat, provide

at least 50 mm of clearance from the top of the Controller. For the

clearance at the bottom and sides, follow the mounting method.

• Do not install the product immediately above significant heat sources,

such as heaters, transformers, or large-capacity resistors.

• Do not let the ambient temperature exceed 50 °C (122 °F).

• Provide a forced-air fan cooling or air conditioning if the ambient

temperature is near 50 °C (122 °F) so that the ambient temperature

never exceeds 50 °C (122 °F).

●Noise Resistance

• Do not install the product in a cabinet containing high-voltage equipment.

• Do not install the product within 200 mm of power cables.

●Component Installation and Handling

• Touching Signal Lines

To prevent damage from static electricity, use a wrist strap or another

device for preventing electrostatic discharges when touching terminals or

signal lines in connectors.

• Handling a USB Memory

To remove a USB memory, make sure that data is not being read or

written to it.The LED on the USB memory flashes while data is being read

or written, so make sure that it is lit steadily before removing the memory.

• Turning OFF the Power

Do not turn OFF the power while a message is being displayed indicating

that processing is being performed. Data in memory will be corrupted, and

the product may not operate correctly the next time it is started.

• Using the RESET Signal

Do not use the RESET input immediately after power is turned ON. When

using the RESET input to synchronize startup timing, wait at least 15

second after the Controller’ s power supply is turned ON before turning

ON the RESET signal.

• The LCD panel used for the LCD-integrated type (FZ5-110

□/FZ5-110□

-10/FZ5-60□/FZ5-60□-10

) has been made using precision technology,

and sometimes a few pixels are missing in the panel. This is due to the

structure of the LCD panel, and is not a malfunction.

●Maintenance

Turn OFF the power and take safety precautions before conducting

inspections. Electrical shock can result from attempting safety

inspections with the power turned ON.

• Clean the lens with a lens-cleaning cloth or air brush.

• Lightly wipe off dirt with a soft cloth.

• Dirt on the CCD must be removed using an air brush.

• Do not use thinners or benzene.

●Communication with High-order Device

After confirming that this product is started up, communicate with the

high-order device.

When this product has started up, an indefinite signal may be output from

the high-order interface.

To avoid this problem, clear the receiving buffer of your device at initial

operations.

■Component Names and Functions

LED,Connector name

Description

POWER LED

Lit while power is ON.

RUN LED

Lit while the controller is in Run Mode.

ERROR LED

Lit while an error occurs.

I/O connector(control lines, data lines) Connect an external device such as a synchronization sensor and programmable controller.

Camera connector

Connect a camera.

Power/ground terminal

Connect a DC power supply. Wire the power supply unit independently

of other devices. After wiring, replace the terminal cover.

Power/ground terminal

Connect the ground wire. Make sure that the controller is grounded with a separate ground wire.

Monitor connector(analog RGB)

Connect a monitor.

RS-232C/RS-422 connector

Connect an external device such as a programmable controller.

USB connector

Connect a USB device. Do not plug/unplug a USB device while measurement is being

performed. It may affect measurement time and/or destroy data. Do not connect USB

memories to adjacent ports.USB memories may contact each other, resulting in malfunction

and/or corruption.

Ethernet connector

Connect an Ethernet device.

Touch pen (holder)

A touch pen is stored.

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

⑪

⑫

●LCD integrated type

−

Recommended Wire Size: 1.31 to 2.63 mm2

−

Crimping Terminal

−

Terminal Screw: M4

8.5mm max.

8.5mm max.

・

Controller

・・・・・・・・・・・・・・・・

Qty.: 1

・

Instruction Manual (this manual)

・・・・・・

Qty.: 1

・

Mounting bracket (for panel)

・・・・・・・・

Qty.: 6

・

Touch pen

・・・・・・・・・・・・・・・

Qty.: 1

Image Processing System

Model

INSTRUCTION SHEET

Thank you for selecting OMRON product. This sheet

primarily describes precautions required in installing and

operating the product.

Before operating the product, read the sheet thoroughly

to acquire sufficient knowledge of the product. For your

convenience, keep the sheet at your disposal.

The following notice applies only to products that carry the CE mark:

Notice:

This is a class A product. In residential areas it may cause radio

interference, in which case the user may be required to take adequate

measures to reduce interference.

Manufacturer:

Omron Corporation,

Shiokoji Horikawa, Shimogyo-ku,

Kyoto 600-8530 JAPAN

Ayabe Factory

3-2 Narutani, Nakayama-cho,

Ayabe-shi, Kyoto 623-0105 JAPAN

TRACEABILITY INFORMATION:

Representative in EU:

Omron Europe B.V.

Wegalaan 67-69

2132 JD Hoofddorp,

The Netherlands

Meanings of Signal Words

Meanings of Alert Symbols

Alert statements in this Manual

The following alert symbols are used in this manual.

The following alert statements apply to the products in this

manual. Each alert statement also appears at the locations

needed in this manual to attract your attention.

Indicates a potentially hazardous

situation which, if not avoided, will

result in minor or moderate injury, or

may result in serious injury or death.

Additionally there may be significant

property damage.

WARNING

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury or in

property damage.

Indicates general prohibitions for which there is

no specific symbol.

Indicates the possibility of electric shock under

specific conditions.

Indicates the possibility of explosion under

specific conditions.

Indicates the possibility of laser radiation.

Indicates the possibility of injury by high

temperature under specific conditions.

CAUTION

●

Symbols and the meanings for safety precautions

described in this manual.

In order for the product to be used safely, the following

indications are used in this book to draw your attention to

the cautions. The cautions with the indications describe

the important contents for safety.

WARNING

CAUTION

This product must be used according to the

instruction manual. Failure to observe this may

result in impairment of functions and

performance of the product.

This product is not designed or rated for

ensuring safety of persons. Do not use it for

such purposes.

Never connect the AC power supply with this

product. When the AC power supply is

connected, it causes the electric shock and a fire.

A lithium battery is built into the Controller and

may occasionally combust, explode, or burn if

not treated properly. Dispose of the Controller as

industrial waste, and never disassemble, apply

pressure that would deform, heat to 100

℃

or

higher, or incinerate the Controller.

Since camera that can be connected with this

product emits a visible light that may have an

adverse effect on the eyes, do not stare directly

into the light emitted from the LED. If a specular

object is used, take care not to allow reflected

light enter your eyes.

Danger of burns. Do not touch the case while the

LED is ON or just after power is turned OFF,

since it remains extremely hot.

Precautions for Safe Use

• Keep the power supply wires as short as possible

(Max.10m).

• Use a DC power supply with safety measures against high-voltage

spikes(safety extra low-voltage circuits on the secondary side).

●

Installation Environment

• Do not use the product in areas where flammable or explosive

gases are present.

• Install the product so that air can flow freely through its cooling

vents.

• Clean the vent hole and discharge opening to prevent dust or

particles from blocking them. Blocked cooling vents or discharge

opening of the fan increasing heat inside, causing malfunction of

the product.

• Do not install the product close to high-voltage devices and power

devices in order to secure the safety of operation and

maintenance.

• Make sure to tighten all installation screws securely.

●

Power Supply and Wiring

• Make sure to use the product with the power supply voltage

specified by this manual.

• Use the cables and crimping terminals with the specified

dimensions. Do not directly connect an electric wire to the terminal

block that is simply twisted.

・

JIS Class-D grounding (ground resistance: 100 W or less) is

required.

・

The grounding point must be shorter as long as possible so

that the grounding wire should be shorter.

・

The grounding point must be used only for controller itself.

Connecting other devices to the point or connecting the

controller grounding to the building beams may be adversely

affected.

• Do the following confirmations again before turning on the

power supply.

- Is the voltage of the power supply correct? (24VDC)

- Is not the load of the output signal short-circuited?

●Ground

• The controller power circuit is not insulated from its internal circuit.

• When grounding the 24 V DC power supply’ s positive terminal, do

not ground the controller’ s FG terminal or the PLC’ s FG

terminal.

【①、②】

Since the PC’ s shell and the SG (0V) are connected

inside the PC, current would run through the route shown in the

figure below and cause burnout.

• As in the case with a PC, you can safely ground the controller’ s FG

terminal without a problem when there is no possibility that the

SG (0V) and the FG will short-circuit. For information about the PLC

wiring, check the specifications of your PLC before wiring.

• Be sure to use a pedestal when connecting a camera to the

controller.

【③】

As the shell of the camera is the SG (0V), it can

cause short-circuiting between the SG (0V) and the FG if a pedestal

is not used.

• To avoid receiving an electric shock when grounding a positive

terminal, do not touch the SG (0V) (camera, power supply terminal).

1

2

3

Camera

PC

Shell

SG(0V)

0V

SG(0V)

Controller

SG:

FG:

Signal ground

Frame ground

Camera cable

SG

SG

24V

SG

SG

FG

FG

FG

RS-232C

RS-232C

SG

SG

SG FG

FG

PLC

Parallel I/O

connector’s

shell

RS-232C

connector’s shell

Mounting Spacer

(insulator)

FG

Power

supply

Power supply

circuit

The sensor controller is compliant with the standards

below:

EC Directive, 2004/108/EC

EN (European Norm), EN61326-1

UL standard, UL508

●

Other

• Use only the camera and cables designed specifically for the product.

Use of other products may result in malfunction or damage of the

product.

• Always turn OFF the Controller's power before connecting or

disconnecting a camera or cable. Connecting the cable with power

supplied may result in damage of the camera or peripheral devices.

• For the cable that is flexed repeatedly, use the robotic cable type

(flexing resistance type) to prevent damages.

• Do not apply torsion stress to the cable. It may damage the cable.

• Secure the minimum bending radius of the cable. Otherwise the

cable may be damaged.

• Do not attempt to dismantle, repair, or modify the product.

• Should you notice any abnormalities, immediately stop use, turn OFF

the power supply, and contact your OMRON representative.

• The Sensor Controller and camera case are hot while power is

supplied or directly after the controller is turned off. Do not touch the

case.

• Be sure to dispose of the product as industrial waste.

• Do not drop, impose excessive vibration or shock on the product.

Doing so may result in malfunction or burning.

• Since a lithium battery is incorporated, there is a rare case when you

are seriously injured due to firing or blowout.

●

Regulations and Standards

*

Items indicated with an asterisk are dedicated items, and cannot be substituted.

Sensor controller

The Controller performs the image processing specified by

the user settings and outputs the measurement results.

Front view

Touch pen (standard accessory)

Right-side view

*

Camera cable

FZ-VS (2m, 5m,10m, min. bending radius: 69mm)

Bend resistant camera cable

FZ-VSB (2m, 5m, 10m min. bending radius: 69mm)

Right-angle camera cable

FZ-VSL (2m,5m,10m min. bending radius: 69mm)

Long-distance camera cable

FZ-VS2 (15m min. bending radius: 93mm)

Long-distance Right-angle camera cable

FZ-VSL2 (15m min. bending radius: 93mm)

Camera cable

Camera

Standalone camera

FZ-SC/FZ-S/

FZ-SC2M/FZ-S2M/

FZ-SFC/FZ-SF/

FZ-SPC/FZ-SP/

FZ-SHC/FZ-SH

FZ-SC5M2/FZ-S5M2

Intelligent compact camera

FZ-SQ010F/FZ-SQ050F/

FZ-SQ100F/FZ-SQ100N

Intelligent camera

FZ-SLC15/FZ-SLC100

Automatic focus camera

FZ-SZC15/FZ-SZC100

Detects workpieces as images.

*

FZ-VM (2m, 5m, min. bending radius: 75mm)

LCD monitor

Use the monitor to check images and

display the condition-setting menus.

FZ-M08 (8.4-inch)

Monitor cable

*

*

Power Supply

Peripheral Device

Input Device

USB memory

FZ-MEM2G

FZ-MEM8G

Mouse, track ball

(Commercially available USB devices)

Recommended Model by OMRON:

S8VS-18024

*

Camera connector

Ethernet connector

Monitor connector

(analog RGB)

USB connector

RS-232C/RS-422

connector

I/O connector

(control lines, data lines)

Front view

w

e

i

v

e

d

i

s

-t

h

g

i

R

w

e

i

v

e

d

i

s

-t

f

e

L

Power/

ground

terminal

POWER LED

RUN LED

ERROR LED

USB connector

Touch pen (holder)

6 7

1

2

3

10

4

5

8

9

10

11

12