76

Cobra 350 User's Guide

05624-000 Rev. K

5.12 Installing User-Supplied Safety Equipment

DC

IN

24V

GND

AC

200 -

240V

Ø

1

XBEL

TIO

XIO

Servo

ENET

ENET

XSYSTEM

1

2

3

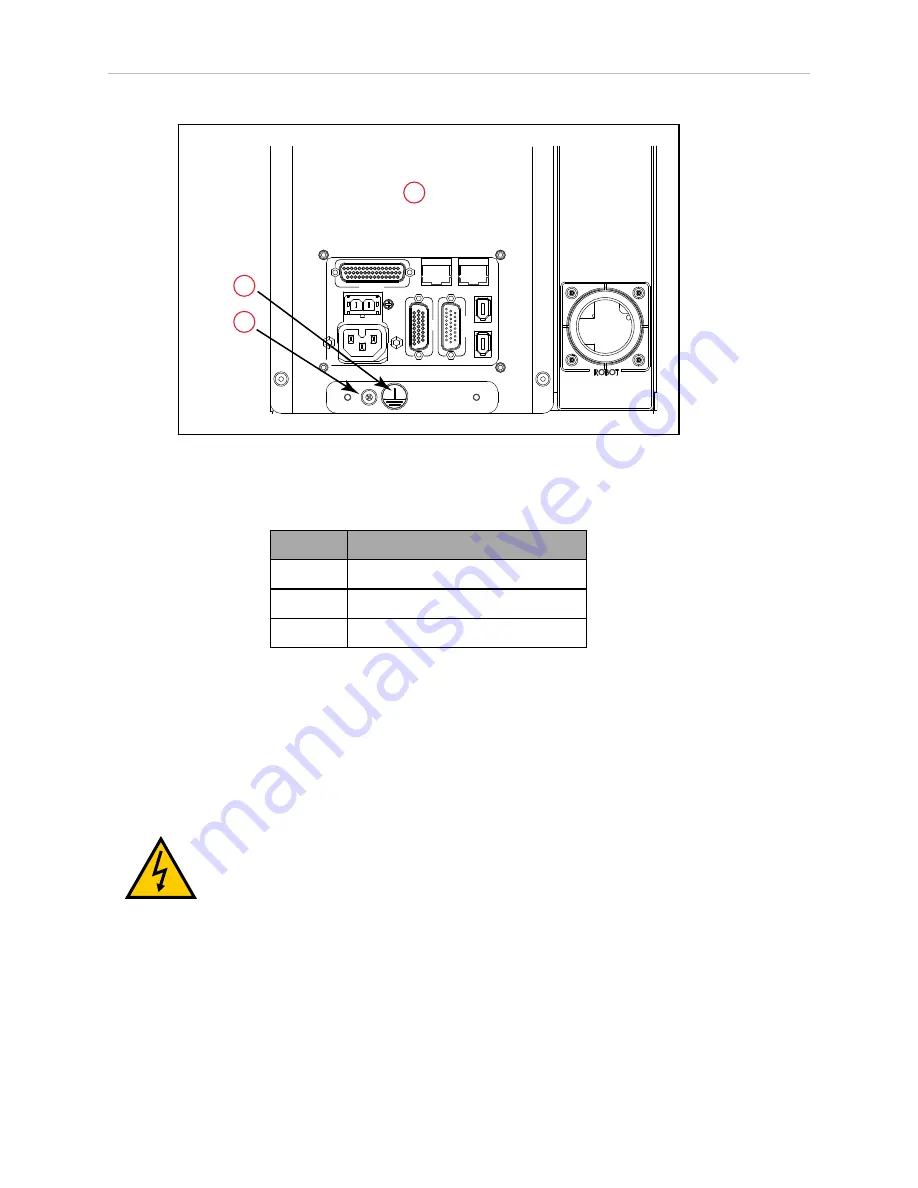

Figure 5-15. Earth Ground Location

Table 5-16. Earth Ground Location Description

Item

Description

1

Robot Interface Panel

2

Ground Label

3

Ground Screw

Robot-Mounted Equipment Grounding

The Cobra 350 Joint 3 quill and tool flange are not reliably grounded to the robot base. If haz-

ardous voltages are present at any user-supplied robot-mounted tooling, you must install a

ground connection from that tooling to the ground point on the robot base. Hazardous

voltages can be considered anything in excess of 30 VAC (42.4 VAC peak) or 60 VDC.

Also, see Tool Flange Dimensions for Cobra 350 Robots (Units in mm) on page 122 for the

grounding point on the tool flange.

WARNING:

ELECTROCUTION RISK

Failing to ground robot-mounted equipment or tooling that uses hazardous

voltages could lead to injury or death of a person touching the end-effector

when an electrical fault condition exists.

5.12 Installing User-Supplied Safety Equipment

The user is responsible for installing safety barriers to protect personnel from coming in con-

tact with the robot unintentionally. Depending on the design of the workcell, safety gates, light

curtains, and emergency stop devices can be used to create a safe environment. Read the

Robot

Safety Guide

for a discussion of safety issues.