EN-18

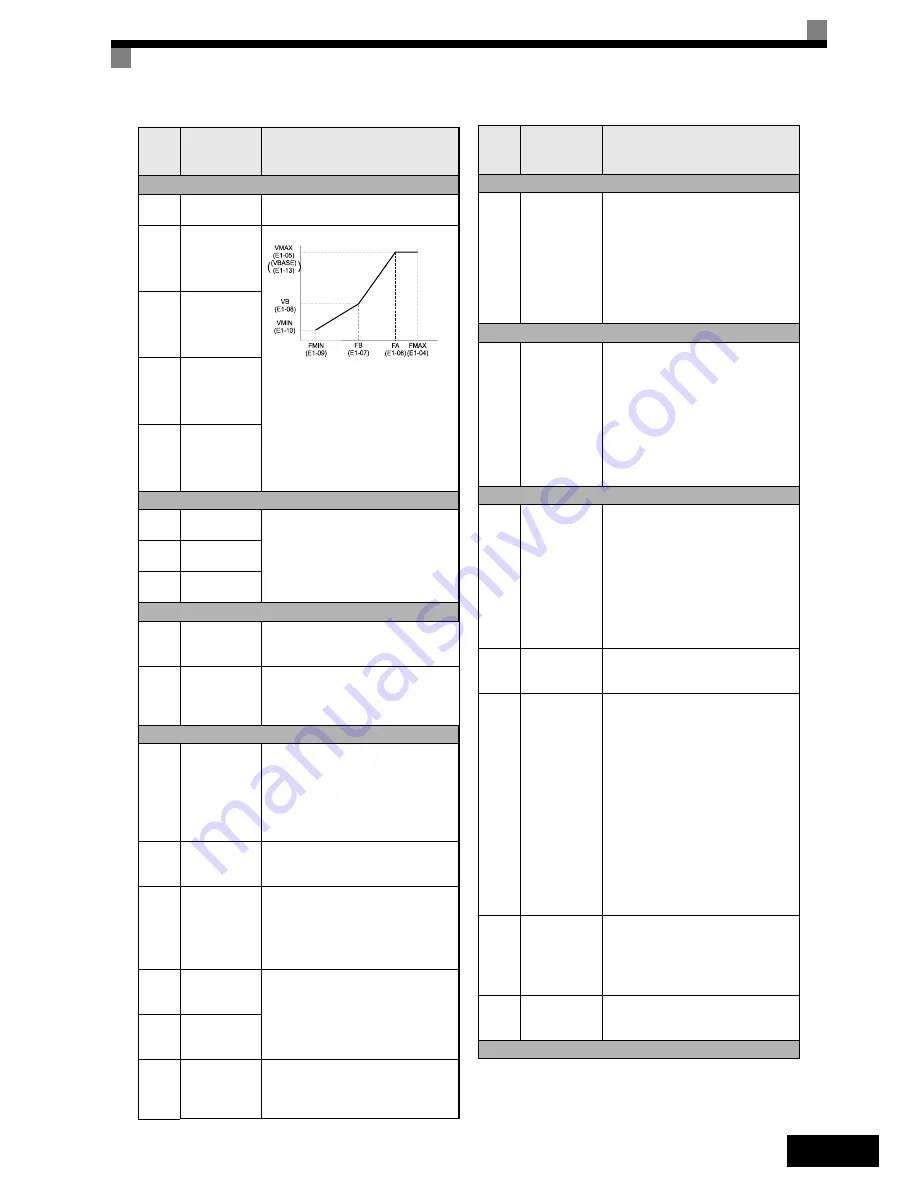

V/f Pattern Settings

E1-01

Input voltage

setting

This setting is used as a reference

value for protection functions.

E1-04

Max. output

frequency

(FMAX)

To set V/f characteristics in a straight

line, set the same values for E1-07

and E1-09. In this case, the setting for

E1-08 will be disregarded.

Always ensure that the four frequen-

cies are set in the following order:

E1-04 (FMAX)

≥

E1-06 (FA) > E1-07

(FB)

≥

E1-09 (FMIN)

E1-05

Max. output

voltage

(VMAX)

E1-06

Base fre-

quency (FA)

E1-13

Base Voltage

(VBASE)

Motor Data Settings

E2-01

Motor rated

current

Sets the motor data. Set the correct

values if the thermal motor protection

is used.

E2-03

Motor no-load

current

E2-05

Motor line-to-

line resistance

Digital I/O Settings

H1-01

to

H1-05

Terminal S3 to

S7 function

selection

Refer to

page 20, Digital Input Func-

tion Selections (H1-01 to H1-05)

for a

list of selections

H2-01

and

H2-02

Terminal M1-

M2 and M3-

M4 function

selection

Refer to

page 20, Digital Output Func-

tion Selections

for a list of selections

Analog I/O Settings

H3-08

Analog input

A2 signal level

selection

Selects the signal level input at multi-

function analog input A2.

0:0 to +10V (11 bit).

2:4 to 20 mA (9-bit input).

3:0 to 20 mA (9-bit input)

Ensure to switch S1-2 to “V” before

using a voltage input.

H3-09

Analog input

A2 function

selection.

Selects the multi-function analog

input function for terminal A2.

H3-13

Terminal A1/

A2 switching

Selects on which terminal the main

frequency reference can be input.

0:Use analog input 1 on terminal A1

for main frequency reference.

1:Use analog input 2 on terminal

A2 for main frequency reference.

H4-01

Terminal FM

monitor selec-

tion

Sets the number of the monitor item

to be output (U1-

) at terminal FM/

AM.

H4-04

Terminal AM

monitor selec-

tion

H4-05

Terminal AM

gain

Sets the analog output AM gain.

Sets the percentage of the monitor

value that is equal to 10V output at

terminal AM.

Param-

eter

Num-

ber

Name

Description

Output Voltage (V)

Frequency (Hz)

Motor Protection

L1-01

Motor protec-

tion selection

0:Disabled

1:General-purpose motor protection

(fan cooled motor)

2:Inverter motor protection (externally

cooled motor)

3:Vector motor protection

When the Inverter power supply is

turned off, the thermal value is

reset, so even if it is enabled, pro-

tection may not be effective.

Power Loss Ride Through

L2-01

Momentary

power loss

detection

0:Disabled (DC bus undervoltage

(UV1) detection)

1:Enabled (Restarted when the

power returns within the time set

in L2-02. When L2-02 is

exceeded, DC bus undervoltage

is detected.)

2:Enabled while CPU is operating.

(Restarts when power returns dur-

ing control operations. Does not

detect DC bus undervoltage.)

Stall Prevention

L3-01

Stall preven-

tion selection

during accel

0:Disabled (Acceleration as set. With

a heavy load, the motor may stall.)

1:Enabled (Acceleration stopped

when L3-02 level is exceeded.

Acceleration starts again when

the current has fallen below the

stall prevention level).

2:Intelligent acceleration mode (Using

the L3-02 level as a basis, accelera-

tion is automatically adjusted. Set

acceleration time is disregarded.)

L3-02

Stall preven-

tion level dur-

ing accel

Effective when L3-01 is set to 1 or 2.

Set as a percentage of Inverter rated

current.

L3-04

Stall preven-

tion selection

during decel

0:Disabled (Deceleration as set. If

deceleration time is too short, a DC

bus overvoltage may result.)

1:Enabled (Deceleration is stopped

when the DC bus voltage

exceeds the stall prevention

level. Deceleration restarts when

the voltage falls below the stall

prevention level again.)

2:Intelligent deceleration mode

(Deceleration rate is automatically

adjusted so that the Inverter can

decelerate in the shortest possible

time. The set deceleration time is

disregarded.)

When a braking option (Braking Unit)

is used, always set to 0.

L3-05

Stall preven-

tion selection

during running

0:Disabled (Runs as set. With a

heavy load, the motor may stall.)

1:Deceleration using deceleration

time 1 (C1-02.)

2:Deceleration using deceleration

time 2 (C1-04.)

L3-06

Stall preven-

tion level dur-

ing running

Effective when L3-05 is 1 or 2.

Set as a percentage of the Inverter

rated current.

Fault Restart

Param-

eter

Num-

ber

Name

Description