6

2.5 CHECK OIL LEVEL

Check the oil level only when the machine is not in operation and all

vacuum built up in the chamber has been vented. Be aware that the oil

may be very hot and avoid all contact.

Checking the Oil Level

* Check the oil level on a daily basis

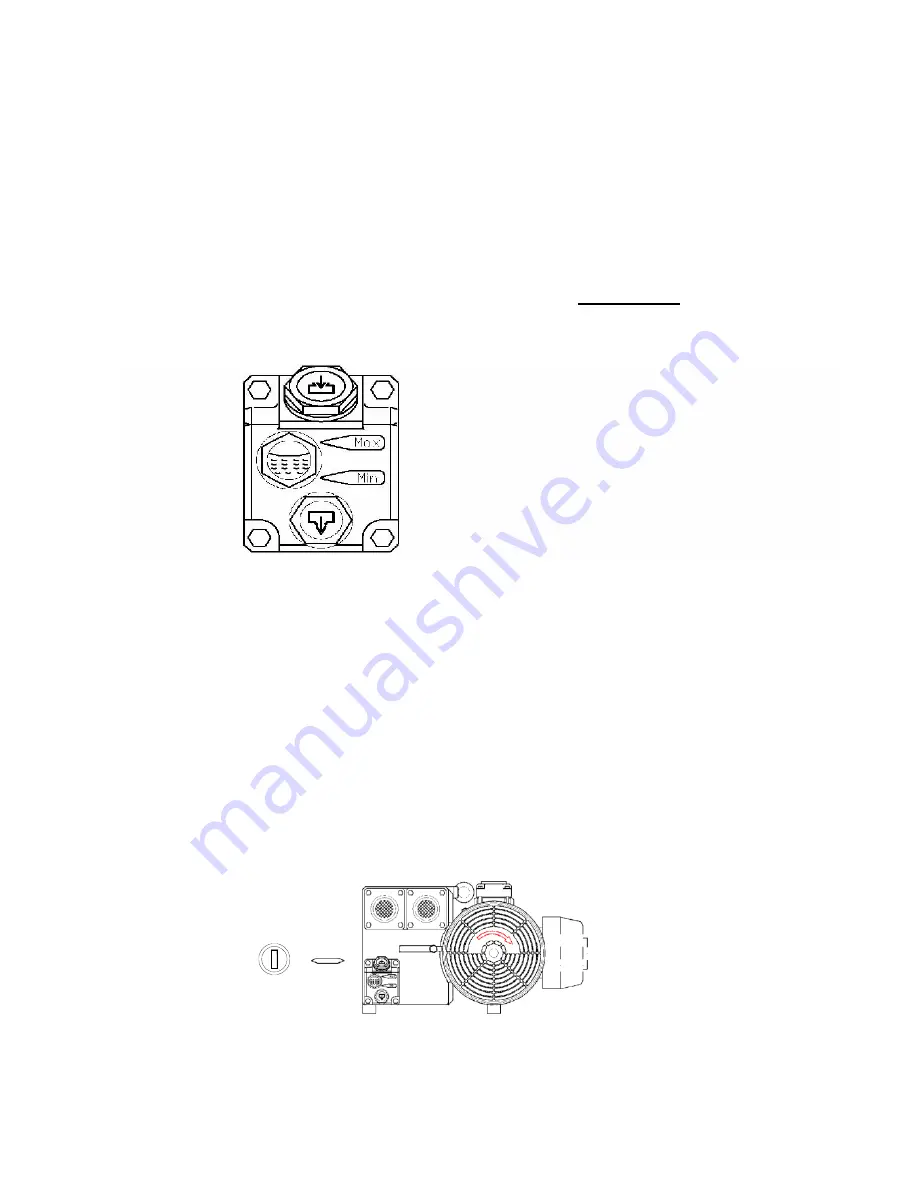

* When checking the oil level use the sight gauge shown in

figure 1 below

. The level

should be between the arrows indicating Minimum and Maximum. If the level is below the

minimum arrow add oil until the maximum arrow is reached.

Figure 1

2.6 POWER CONNECTION

When preparing to install the machine’s main power connection please refer to the electrical

information on the serial number plate located on the machine’s back panel. A certified

electrician should be employed to complete this connection.

2.7 VACUUM PUMP ROTATION

If your machine operates on 3 phase power it is important to check the rotation of the vacuum

pump. The pump should turn in the direction indicated in

Figure 2

below. If the pump turns

in the wrong direction it will make a sound that is obviously wrong. Turn off the power

immediately and change the position of two of the power wires and retest.

Figure 2

Main switch