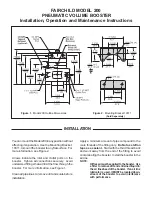

13

Parts Breakdown

Model LAR-25PMB

31502

Description

Position

Description

Position

Description

Position

Logo 120mm

00047.7

Clamp K22-LM (T-80I)

12469.9

ETIQ.FIO TERRA E / F / I / P 32258.0

Elast.6x22 Pin Din 1481

00212.7

FIO Connect GROUND WIRE

13737.5

ETIQ.ATENCAO GROUND

WIRE

32259.8

Dowel Wire Mold 092 231

00218.6

CH.TEC.30223

M2FT2EE3G136

13821.5

PEDAL (ASH)

34320.0

Elast.6x50 Pin Din 1481

00267.4

PFS M6x8 DIN 7985 ZB

14174.7

ETIQ.LIMPEZA /

MAINTENANCE

34686.1

PFS UNC3 FRI / 8 “x7 / 8”

RTZB

00711.0

SPACER

14644.7

EP RUBBER

34895.3

Term. Pre-ISOL.EF-4228

01213.0

CENTRAL BEARING WITH

BUSH

14650.1

CS STAND (ASH)

35111.3

PCA M8 DIN 934 ZB

02729.4

PCA FRI LOW M22x1, 5

14653.6

MOTOR SUPPORT (ASH)

35112.1

ARR.L.A8, 4 DIN 125 ZB

02730.8

WASHER FIBER 0.6X13X23

14654.4

PROTECTION PLATE (ASH) 35113.0

PCA M6 DIN 934 ZB

03099.6

PCA ACAB.M10x1 25 RE INOX 14660.9

PROTECTION OF WIRES

280mm

35613.1

PCA M5 DIN 934 ZB

03145.3

ENGAGEMENT COMPL. - LB

15815.1

overcap MB

40753.4

PFS M6x8 DIN 916 phosphite. 03188.7

FLANGE ENGAGEMENT-LB

15816.0

COVER 25 (FE006-112)

40775.5

CB.3x2, 5mm2x1800mm

A.P.V.

03656.0

The 25 CHAPEU LAR/LS-04

17456.4

CS HELICE TYPE MB

40830.1

PFS M3x6 DIN 7985 ZB

04208.0

TERM.POSITIV LOCK 1 A 2.5

17581.1

CS CUP LAR-25MB

40859.0

THE SPRING ROCKER

04870.4

COVER P / FEMALE

TERMINAL

17582.0

BEARING COMPLETE

40867.0

COAT PIN FLANGE

05041.5

KEY SELECTOR C /

TERMINAL

18250.8

AXIS CENTR.LAR/LB-

15/25MB

40868.9

ETIQ.ATENCAO

110/220/380V

05504.2

PFS M8x16 DIN 933 ZB

19059.4

FULL CUP - LAR-25LMB

40872.7

PFS M8x40 DIN 933 ZB

09008.5

deflecting

19148.5

CS SUPPORT Dump. (ASH)

41009.8

RING VED.MANCAL

MD.112410

09167.7

ARR.L.A5, 3 DIN 125 INOX

20194.4

PE RECTANGULAR

(MOL.483753)

46767.7

ARR.L.A10, 5 DIN 125 ZB

09338.6

RING V’RING 16,5 x10, 5x5, 5

20378.5

ETIQ.LIMPEZA /

MAINTENANCE

50665.6

ETIQ.IDENTIF.MOTOR/

RESIST

09637.7

MOTOR 60Hz 1.5 HP W

28733.4

ARR.L.A8, 4 DIN 125 INOX

12460.5

PFS AUTO BROC.4, 2x13 ZB

29442.0

Summary of Contents for 31502

Page 10: ...10 Parts Breakdown Model LAR 15PMB 37969 ...

Page 12: ...12 Parts Breakdown Model LAR 25PMB 31502 ...

Page 14: ...14 Electrical Schematics Model LAR 15PMB 37969 ...

Page 15: ...15 Electrical Schematics Model LAR 25PMB 31502 ...

Page 16: ...16 ...

Page 18: ......

Page 19: ......