PAGE 6

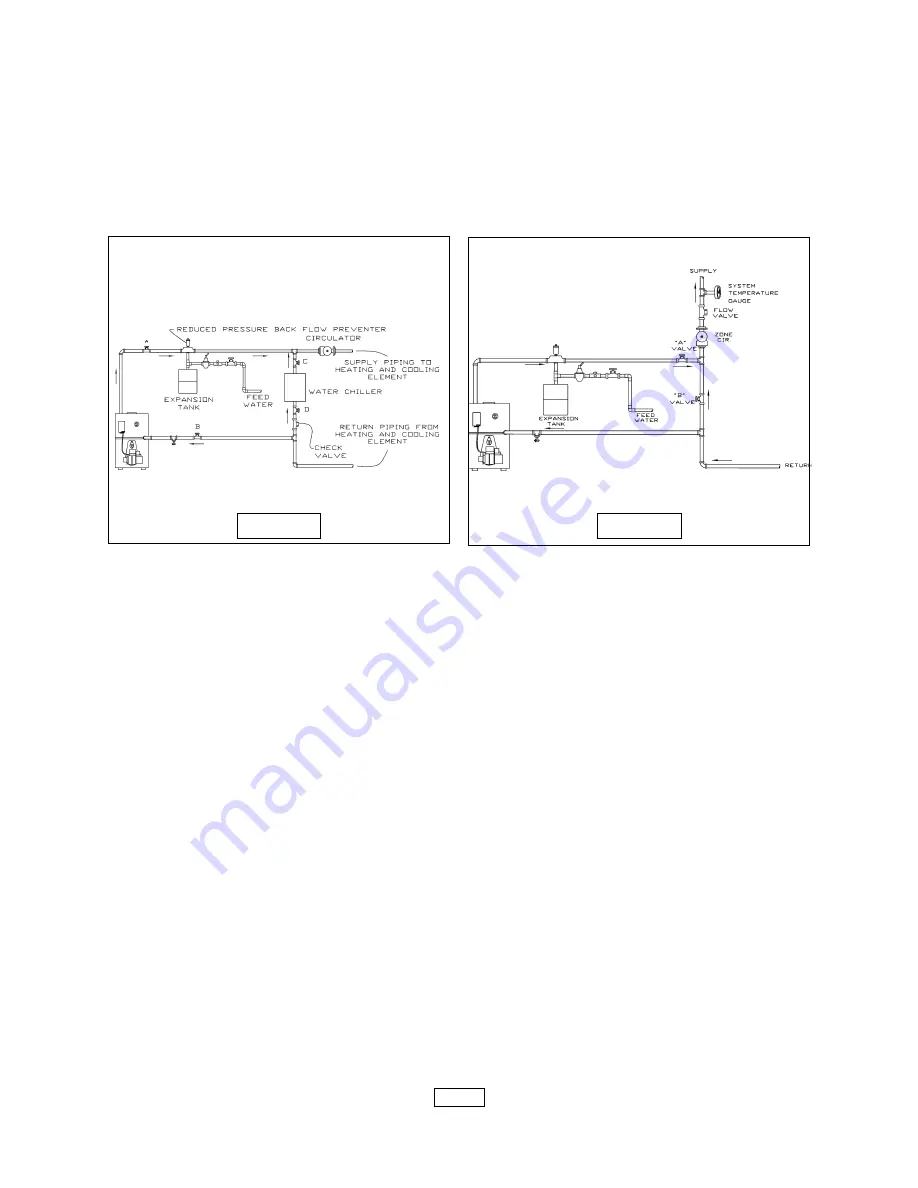

CONNECTING SUPPLY AND RETURN PIPING

1. Connect supply and return piping as suggested in

figure 5, below. When the boiler is

used in connection with refrigerated systems:

A. The chilled medium MUST BE IN PARALLEL with the boiler.

B. Use appropriate valves to prevent the chilled medium from entering the heating

boiler.

2. During the heating cycle open valves

A

and

B

, close valves

C

and

D

.

3. During heating cooling cycle open valves

C

and

D

, close valves

A

and

B

.

A. Maintain a minimum clearance of one inch to hot water pipes.

In air handling units where they may be exposed to refrigerated air circulation, the boiler

piping system

MUST

be supplied with flow control valves or other automatic means to

prevent gravity circulation of the boiler water during the cooling cycle.

4. Hot water boilers installed above radiation level must be provided with a low water

device either as part of the boiler or at the time of boiler installation.

5. When a boiler is connected to a heating system that utilizes multiple zoned

circulators, each circulator must be supplied with a flow control valve to prevent gravity

circulation.

*

Reduced pressure back flow preventer must be present under provisions required by

the Environmental Protection Agency, (EPA).

6. Bypass piping is an option which gives the ability to adjust the supply boiler water

temperature to fit the system or condition of the installation. Although, this method of

piping is not typically required for baseboard heating systems.

A. This method is used to protect systems using radiant panels and the material they

are encased in from high temperature supply water from the boiler. See figure 6

above.

B. This method is used to protect boilers from condensate forming due to low

temperature return water. Generally noticed in large converted gravity systems or other

large water volume systems. See figure 7 on page 7.

FIGURE 6

FIGURE 5