89

Item No.

2

3

Items

AG Plate Gap

Auto Gap Correction

Standard Value

C=0.14

±

0.02mm

Illustration

3

Turn on the printer while pressing

Switches

B

and

C

.

4

The auto gap correction has completed

if “Av” is printed.

Adjustment Method

1

Insert the thickness gauge between

the AG frame and the AG plate to veri-

fy the gap value C is between 0.12 and

0.16 mm.

2

If adjustment is required, screw down

the mounting screws and adjust the ec-

centric collar to make the protector gap

value C between 0.12 and 0.16 mm,

then fix the AG plate.

Notes:

After this Adjustment, the Auto Gap

Correction should be conducted (See

item 3)

1

Set the continuous form (1P, 15 in.

wide and 55 Kg) at the printing valid po-

sition and also the ribbon cassette.

2

Turn off the printer, then power on

again while pressing Switches

B

and

C

to conduct the auto correction. If the

auto gap operation has been repeated

3 times and “Av= “ printed, it is the

end of the auto gap correction.

3

The auto correction value from 09 H

to 18 H is desirable. If any value other

than this is indicated, the AG plate gap

should be adjusted again. (See Item 2)

Notes:

a) In the following cases, this adjust-

ment should be implemented.

i)After the gap adjustment between the

AG frame and the AG plate;

ii)After replacing the control board. (not

required after CG/PROGROM, EE-

PROM replacement)

b) When the correction value “Av= “ is

not between 09 and 18, “Warning” will

be indicated on the LCD panel. Press

Switch 1 to reset this warning.

c) The correction value “Av= “ from

09 to 18 is desirable. If any value oth-

er than this is indicated, the gap bet-

ween the AG frame and the AG plate

should be adjusted again to the prop-

er range as described in Item 2.

Then, conduct this correction.

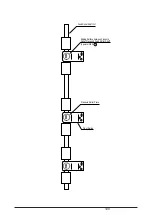

C

AG Frame

AG Plate

Eccentric Collar

Carriage Frame

Mounting Screws

PARK

TEAR

PATH

ONLINE

RESET

GROUP

POWER

ALARM

ITEM OPTION

MENU

STORE

TOF

SHIFT

O N - L I N E E P S

F R O N T F E E D

CONFIG

LF

MicroFeed

Down

FF/LOAD

MicroFeed

Up

1

2

3

4

5

6

7

8

9

0

A

B

C

1

2

3

1st = 0EH

2nd = 0DH

3rd = 0EH

AVE = 0EH

Summary of Contents for PACEMARK 4410

Page 2: ...1 PACEMARK 4410 PRINTER Service Manual...

Page 53: ...52 Figure 3 1 3 2 Parts Layout...

Page 96: ...95...

Page 152: ...151 No Yes End Replace PHA Board Recovered No Yes End Replace PMA Board...

Page 180: ...120 Knob Assy 40782001 8 4 6 3 5 10 7 1 2 9...

Page 182: ...122 Ribbon Assy Feed 40506101 1 15 8 7 8 14 6 5 10 13 3 4 13 2 6 7 14 9 11 11 1...

Page 184: ...124 Sprocket Assy L 40507601 3 2 5 6 1 19 19 7 4 21 10 8 9 20 18...

Page 186: ...126 Sprocket Assy R 40508101 3 7 11 11 1 6 5 2 13 4...

Page 190: ...130 Sheet Feeder Assy R Rear 40509101 8 11 1 9 4 13 13 10 6 5 2 9 12 7 3 Pin Protrusion...

Page 196: ...136 Front Cover Assy 40677201 ODA 40677202 OEL 10 6 9 9 9 2 4 4 1 3 7 7 5 9 10 10 6 6...

Page 198: ...138 Rear Cover Assy 40678301 11 6 5 9 10 10 8 10 10 10 9 4 1 10 3 2 7 13...

Page 202: ...142 Frame Assy OpePane 40755801 3 2 4 6 8 9 9 1 5...

Page 204: ...144 PMA PDA PCB Assy 40752201 4075202 4 or 6 5 or 7 1 or 2 3 8 9 11...