Version 1.1

17

2011-06-28

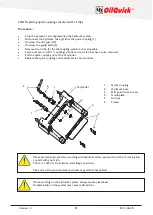

Move the tilt cylinder in until the quick coupler is at an angle of 30-45 degrees to the attachment frame

on the tool (see illustration below).

Hook the fingers at the front of the quick coupler onto the front attachment frame pin.

Raise the attachment from the ground until it hangs freely.

Move the tilt cylinder out, lowering the rear part of the quick coupler to the rear pin on the attachment.

Disable the lock switch for the quick coupler. The light and the alarm both go off.

Move the tilt cylinder to its end position, enabling pressure to build up and the H-cylinder to lock the

attachment. At the same time any hydraulic and electric couplings in use are connected.

Make sure that the indicator rod is

NOT

visible (3).

Make sure that the locking plungers are located under the rear pin on the attachment frame (4).

3

4

Right

Wrong

7.1

Checking hydraulic tools

Try using a hydraulic function on the attach-

ment. If it works properly, the connection is

correct.

Finished.

7.2

Checking mechanical tools without

hydraulic system

Carry out the lock test as described in section 8.

Finished.

ca 30 cm

30°

-

45°

You must always check that the attachment

is locked as described in 7.1 or 7.2.

If in doubt, disconnect the attachment and

find the cause.

See also troubleshooting.

Summary of Contents for OQ 70/55

Page 4: ......

Page 30: ...Version 1 1 30 2011 06 28 Notes...