Sauna & Steam

Oceanic Saunas 01902 450 550 [email protected]

10

Steam Generator Manual

7. Installation

• Isolate the power supply before installation

• Confirm the model you have selected is suitable for your steam room, please refer to chart 5

• Mount the steam inlet nozzle approximately 300mm up from the floor and it should be at least

200mm from person’s body.

• If the steam generator is installed in an inaccessible place ensure that both the electrical

power and water supply can be isolated in an emergency.

• To use the steam generator in single phase the L1 L2 and L3 must be linked together with

the copper bridges that are supplied. This is not possible with the 4kw machine. See circuit

diagram on page 15.

• The minimum water inlet pressure is 0.25 bar (2.5 Mpascals) and the maximum is 2 bar (20

Mpascals), for pressures in excess of this use a reducer before the valve.

• The steam pipe from steam generator to steam room should be kept to a minimum, pipes

longer than 3 meters should be insulated to prevent heat loss. Steam pipes will be hot during

use and must be protected against accidental contact. Steam entering the steam room will

be scalding hot; take care to position the inlet nozzle away from where users will sit and/or

provide adequate guarding, post a notice to caution users.

• Keep the number of right angle bends to a minimum and ensure that the run does not create

a trap into which condensate would gather and cause a blockage I.e. the pipe must not go

down and then up.

• There must be no valve or other blockage in the steam pipe

• The steam pipe should be metal of other material that can endure 150°C temperature, copper

pipe is recommended.

• It is not recommended to install the Steam generator outdoors or where it might be affected

by frost. Allow for a minimum space of 0.5 cubic meters to install the generator.

• Steam generator should be level side-to-side and front to back and should be installed so that

the arrows on the case point up.

• Do not install the steam generator in close proximity to hazardous substances.

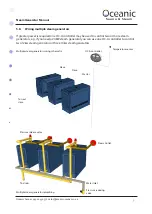

7.1. Generator Size

The table opposite should be referred to for guidance only.

Please note that the size of generator required to heat a

particular size of steam room will vary according to a number of

factors including the type of material used for construction, the

height of the steam room and the ambient temperature.

For lightweight materials such as plastics and laminates 1 KW will

heat up to 1 cubic meter of air for dense materials such as stones

and ceramics which will conduct the heat away more rapidly allow

for up to 2KW per cubic meter of air. Hot air rises so restricting the

height to around 2 meters will ensure the user is sitting in the steam

for higher ceilings you may need to increase the power requirement.

The following table is given as a guide; ambient air temperatures

and frequency of use (number of door openings) can also affect the

power requirements.

Generator Model

Steam Room

Volume (m

3

)

OC-40

1.8 - 4

OC-60

4.5 - 6

OC-80

4 - 7

OC-70

5 - 9

OC-90

6 - 10

OC105

7 - 11

OC-120

8 - 12

OC-140

11 - 15