Open

Vertical

Electric

24

www.nuvair.com

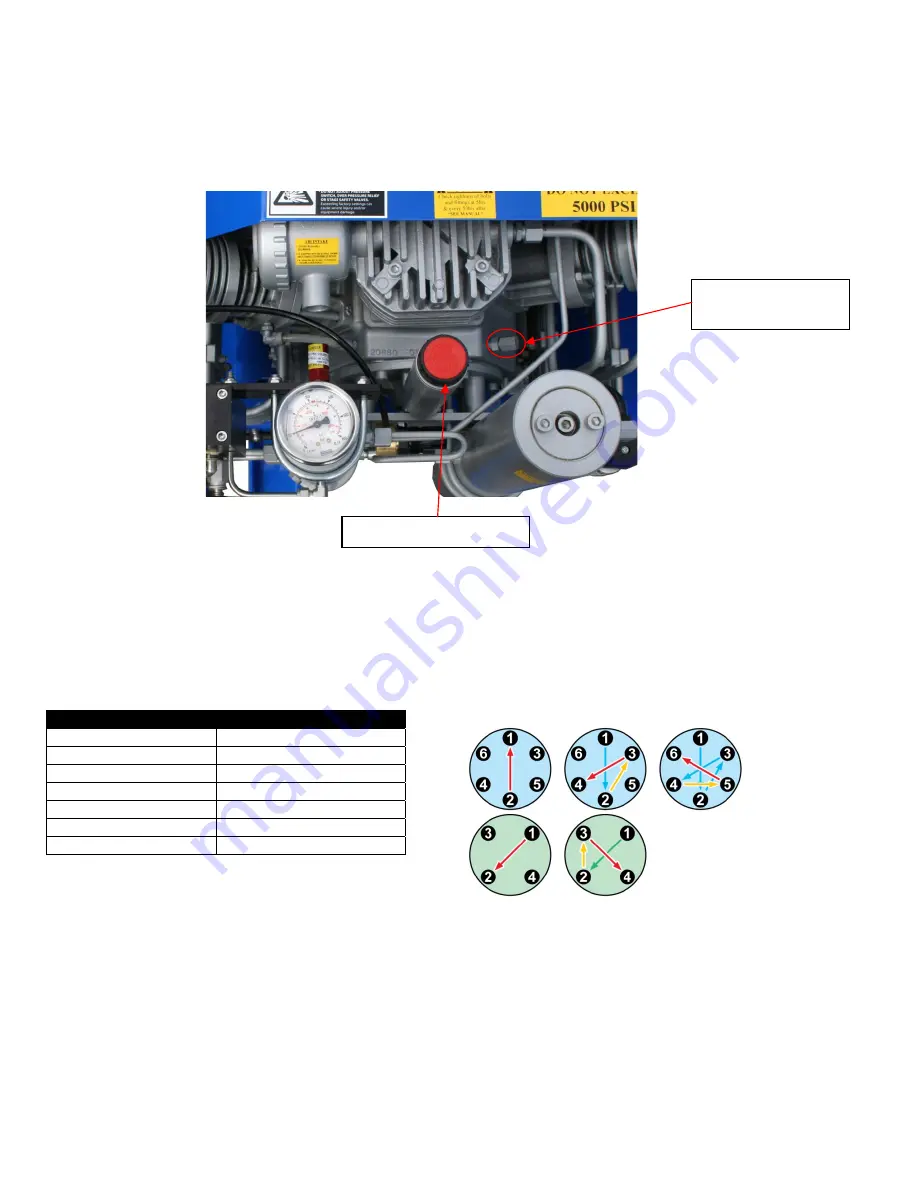

Place a catch container under the oil drain valve. Remove the oil fill cap and crank case breather cap.

Open the drain valve and empty all oil from the machine. Close the drain valve. Pour fresh oil into the

oil fill tube until the oil level is between the top and halfway point on the oil level tube. Replace the

crankcase breather cap and oil fill cap. Run the machine for a few minutes, then shut off and ensure

that the oil returns to the desired level. Adjust oil level if necessary.

15.3 Tightening Torque Values –

Should be done at 50 hour maintenance

The table below shows tightening torques for bolts or hexagonal-head screws or socket screws

lubricated with grease, except for specific cases indicated in the manual. Pipe connections (swivel

nuts) should be finger tight plus an additional 1/2 turn.

6 bolt and 4 bolt torque sequence

15.4 Optional Visual CO / Moisture Monitor

This element contains a CO indicating button and a humidity element in the form of a strip about

1/4in. wide and 3/4in. long. These items need to be installed per the manufacturer’s instructions

provided in the sealed foil packaging. When doing routine maintenance it is highly recommended

these indicators are checked for damage and functionality or be replaced.

Tightening Torque Values

Thread

Maximum Torque

M6 - 1/4”

10

Nm (

7

ft-lbs)

M8 - 5/16”

25

Nm (

18

ft-lbs)

M10 - 3/8”

45

Nm (

32

ft-lbs)

M12 - 1/2”

75

Nm (

53

ft-lbs)

M14 - 9/16”

120

Nm (

85

ft-lbs)

M16 - 5/8”

200

Nm (

141

ft-lbs)

Oil Fill Cap

Crank Case

Breather Cap