G3 Series EtherNet/IP

TM

Technical Manual

Page 7-52

TDG3EPTM1-9EN

05/18

Subject to change without notice

www.asco.com/g3

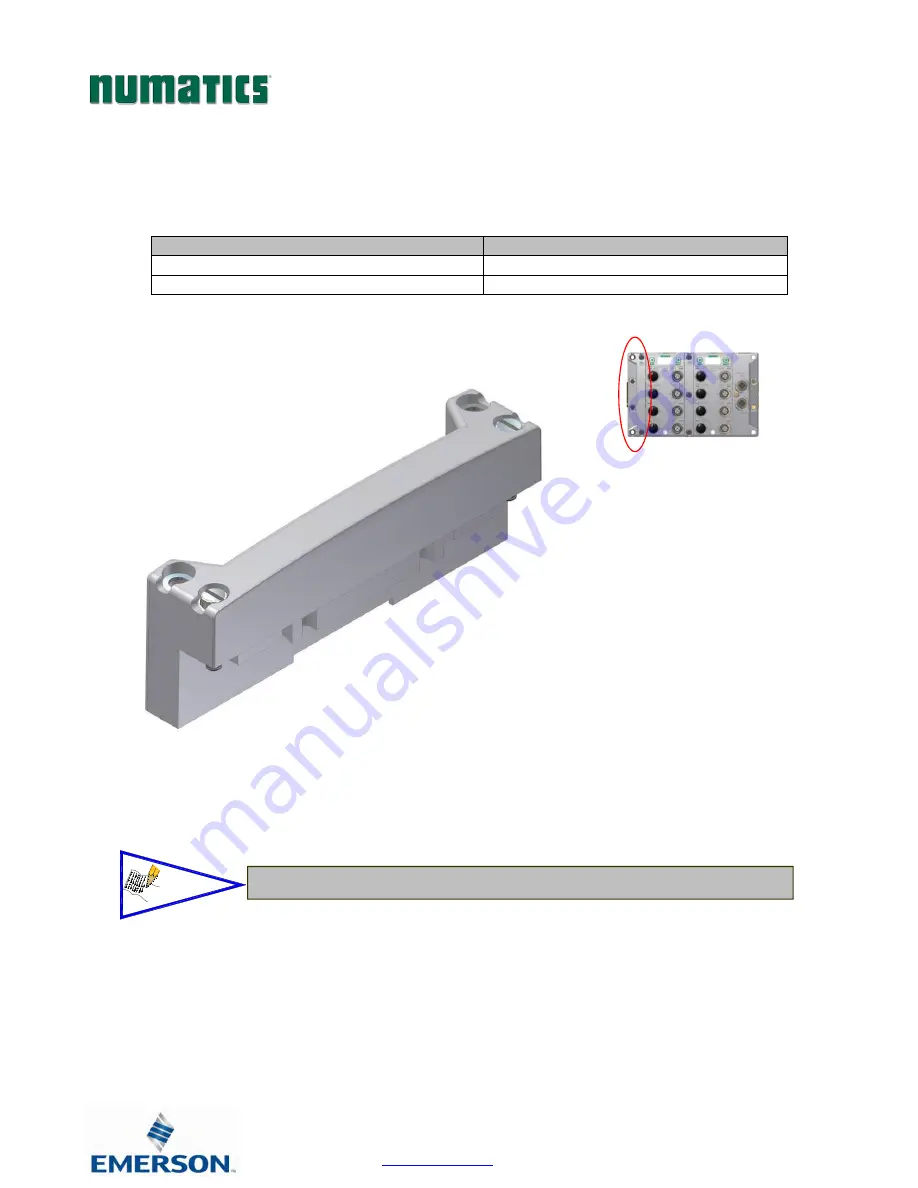

Terminator Module

•

Used to terminate SUB-BUS connections.

o

Must be installed on the left side of the last Sub-Bus module.

Description

Part Number

Terminator Module with Din Rail Mounting

240-245

Terminator Module without Din Rail Mounting

240-184

NOTE!

•

The terminator must be installed in the G3 system for proper operation.