PAGE 8

TONE ARM SETUP

TONE ARM SETUP

A properly adjusted tone arm and cartridge setup will minimize vinyl record wear and optimize the

performance of the turntable. Follow these simple steps for setting the tone arm on the turntable:

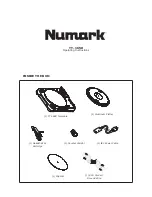

Balancing the Tone Arm

1. Begin the balancing process by lifting the cue lever to the up position (or make sure that the stylus

protector is on the cartridge.)

2. Next, rotate the counterweight clockwise until it is in the complete forward position (NOTE: this is also

the maximum amount of pressure that can be applied to the cartridge.)

3. Now there should be a feeling of weight and resistance when the head shell is raised and lowered.

Begin rotating the counterweight counter-clockwise (away from the pivot point) until this weight and

resistance feeling is gone. If done properly, the tone arm will pivot with very little resistance back and

forth indicating that there is exactly 0 grams of stylus pressure.

4. With the counterweight in its new position further away from tone arm pivot point, grasp the scale ring

of the counter weight and rotate it until "0" is in the vertical position.

5. Finally, rotate the counterweight (and scale ring) clockwise (towards the pivot point) until the desired

amount of weight is reached. If the scale rotates 360 degrees beyond the zero point, the new scale

ring reading should be added to 3.5.

*The included head shell and cartridge assembly requires a minimum of 3 grams and no more than 5

grams for optimum performance.

Setting the Anti-Skate Adjustment

In most cases, the Anti-Skate should be set to its minimum setting. Anti-Skate compensates for inward

tracking forces that occur with certain cartridges when the stylus nears the center of the record. If the

turntable is experiencing excessive skipping during back-cueing and scratching while nearing the center

spindle, try increasing the Anti-Skate in the increments indicated on the dial. Start by adding an

increment of 1, test its performance, than increase it more, and so on.

1.

2.

3.

+

-

=

=

4.

0

3

2.5

2

1.5

1

0.5

Only Rotate

Scale Ring!

5.

0

3

2.5

2

1.5

1

0.5

0

3

2.5

2

1.5

1

0.5

+

360

o

4.5 grams =

MIN

MAX