Standard Assessment Procedure 2005 – Appendix Q MVHR Installation Guide

Page 2 of 6

Introduction

This document is to be used in support of the SAP Appendix Q scheme which provides

tested performance values for MVHR products.

Note that all checklist items must be answered YES in order for the SAP Appendix Q

test figures to be used in ‘As built’ SAP calculations. If any checklist items are answered

NO then SAP default figures must be used. Systems must be designed by a

manufacturer designer and sized correctly to qualify for SAP Appendix Q figures.

SECTION 1:

INSTALLATION GUIDANCE

1. Ductwork Installation

Decision

Yes, No or

N/A

Have the ducts been installed with as little air resistance and

leakages as possible (flexible ducts should be avoided)?

Note: Refer to HVCA DW/143 document ‘A Practical Guide to Ductwork Leakage

Testing’ for detailed guidance on air tightness. Rigid plastic ducting is

recommended and flexible duct should only be used in very short lengths and

mainly just to connect the ductwork to the units/diffusers or to overcome particular

obstructions.

If flexible ducting has been used, has it been pulled taut to minimise

system resistance?

Has the number of duct bends been minimised to ensure adequate

air flow and least resistance? Bends should have a minimum radius

at least the same as the diameter of the ducting used?

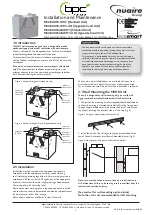

Refer to Figure 1 if using flexible ducting

Have the fans and ducting placed in unheated voids been insulated

to reduce the possibility of condensation forming (see notes below)?

Note: Ducts should be insulated with the equivalent of at least 25mm of insulating

material with a thermal conductivity of 0.04W/mK. Where a duct rises vertically it

may be necessary to fit a condensation trap in order to prevent backflow of any

moisture in the product. Insulation should be applied to both warm and cold air

ducts. Cold air ducts should be wrapped additionally with a vapour barrier outside

the insulation. Ducts with cold air running in warm environments will condense on

the outside of the duct.

Have recommended duct jointing collars and components been

used to ensure appropriate duct performance (duct runs should be

as air tight as possible)?

Note: All the joints should be sealed correctly either using duct tape or silicon.