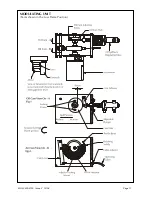

BURNER HEAD DETAILS & ELECTRODE SETTING ………………………………………………………………

24

FUEL PUMPS

- SUNTEC ………………………………………………………………………………………

25

- HP TECHNIK …………………………………………………………………………………

26

FLAME FAILURE & SEQUENCE CONTROL & MODULATING CONTROL SYSTEMS …………………………

27

BURNER OIL NOZZLE …………………………………………………………………………………………….. 31

SERVICE & REPLACEMENT ………………………………………………………………………………………….

31

APPENDIX

Burner Performance Graph

…………………………………………………………………………………..

32

Commissioning Sheet

…………………………………………………………………………………..

33

IMPORTANT – SAFETY

It is essential that the following instructions and adjustments are carried out by qualified engineers that are

experienced in forced draught gas and pressure jet oil burner commissioning. In the UK it is a legal

requirement that these engineers should also be CORGI registered. Nu-way cannot be held responsible

for any consequential damage, loss or personal injury as a result of customers failing to follow these

instructions, or as a result of misuse. Your attention is drawn to the

Emergency Instructions

on Page 14.

EUROPEAN BOILER EFFICIENCY DIRECTIVE (B.E.D.)

All burners and boiler bodies marketed separately should comply with EN 267 (oil burners) or EN676 (gas

burners) and EN303-1 (boiler bodies).

Burner adjustments must be made in accordance with boiler manufacturer’s instructions, and these must

include flue gas temperatures, average water temperature, and CO

2

or O

2

concentration.

MOL 3400 & MOL 4100 Issue 2 08/08

Page 2

Summary of Contents for MOL 3400-410

Page 18: ...MOL 3400 4100 Issue 2 10 08 Page 17 MODULATING UNIT Cams shown in the Low Flame Position...

Page 35: ...NOTES...

Page 36: ...NOTES...