3-15

3.5.1 Manual Mode Input/Output Status Reading

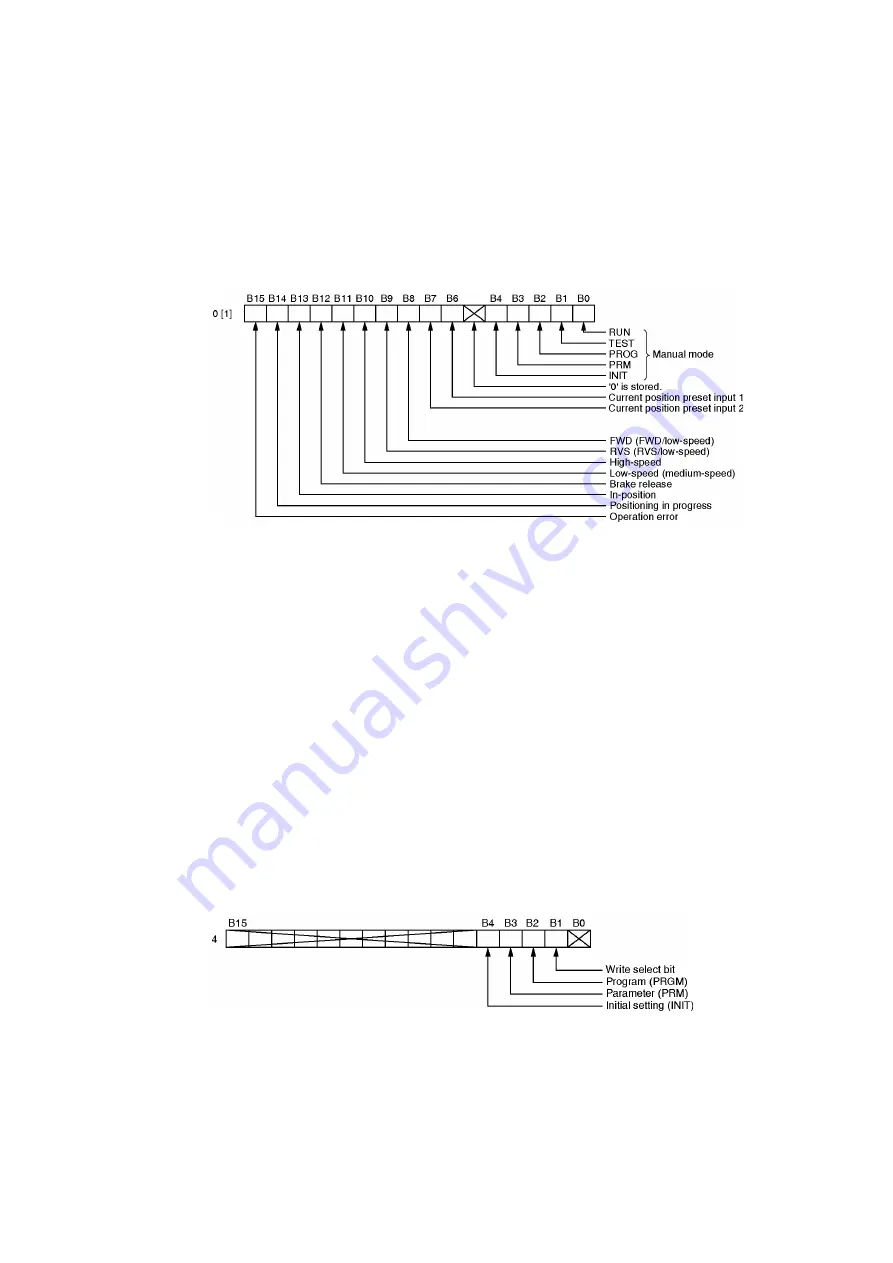

The following status are read.

(1) Manual mode using the VS-T62 or VS-T62B

The bit which corresponds to the selected manual mode (specified from the external setting

unit VS-T62 or VS-T62B) is set to "1". If the external setting unit is not being used, "B0"

becomes "1".

(2) Current position preset input status

Becomes "1" when the relevant current position preset input switches on.

(3) Output status

Becomes "1" when the relevant output switches on.

3.5.2 Error Code Reading

Error codes are read when errors occur. Error codes can be cleared by the following operations.

(1) Turn the "error reset" (command 1: 6 bit) command on from the sequence data.

(2) Turn the power off.

(3) Press the [CLR] key at the external setting unit (VS-T62 or VS-T62B).

(4) Change the Manual mode's mode (mode selected from external setting device).

(5) Change the Sequence mode's mode (mode selected from PLC).

3.5.3 Function Selection (Parameter Writing)

VS-212DN offers the following settings: "0" (joint usage for positioning), "1"(limit switch output only),

and "2" (current position detection only). However, only the "0" setting should be selected (this is the

default setting). Operation cannot be guaranteed if any setting other than "0" is selected.

3.5.4 Sequence Mode Selection Writing

This is the area where the appropriate mode for data writing conditions is selected when writing the

parameter data and the limit switch output ON/OFF data from the PLC CPU. This mode is selected by

the PLC CPU. Therefore, this is called 'sequence mode' to distinguish it from the mode (manual

mode) selected by the VS-T62 or VS-T62B.

Set '1' to the bit corresponding to the desired sequence mode when RUN or TEST in manual mode is

selected. Set '0' to other bits. Setting '1' to both bits will cause an error. The data written to the

buffer memory for data communication with the PC CPU is loaded to the VS-212DN when the PLC

Ready signal (command 1: 7 bit) is turned ON in sequence mode.

Even when sequence mode is selected, if manual mode is changed o anything other than RUN or

TEST, priority is given to manual mode.

(a) Current position is set by INIT in sequence mode.

(b) Program is written by PRGM in sequence mode

Set '1' when writing in the above cases. Become “0” as a default value when power ON.

Summary of Contents for Varlimit VS-212DN

Page 1: ...U S E R S MAN U AL V S 2 1 2 DN NSP Z2004 7...

Page 2: ......

Page 47: ...5 1 5 Operations 5 1 Operating Sequence Flowchart An operation flowchart is shown below...

Page 52: ...6 2 6 1 Pre Operation Setting Sequence...

Page 64: ...6 14...

Page 66: ...6 16...

Page 90: ...7 22...

Page 102: ...8 11...

Page 104: ...8 13...

Page 105: ...8 14...

Page 106: ...8 15...

Page 109: ...8 18...

Page 110: ...8 19...

Page 111: ...8 20...

Page 113: ...8 22...

Page 114: ...8 23...

Page 115: ...8 24...

Page 121: ...10 1 10 DIMENSIONS 10 1 VS 212DN Units mm...

Page 124: ...10 4 10 4 ABSOCODER sensor Units mm...

Page 125: ...10 5 Units mm...

Page 126: ...10 6 10 5 Extension Cable 1 4P S 0102 L 4P RBT 0102 L Units mm...

Page 128: ......

Page 129: ......

Page 130: ......

Page 131: ......

Page 132: ......

Page 133: ......

Page 134: ......