Controller N1200

NOVUS AUTOMATION

2 / 13

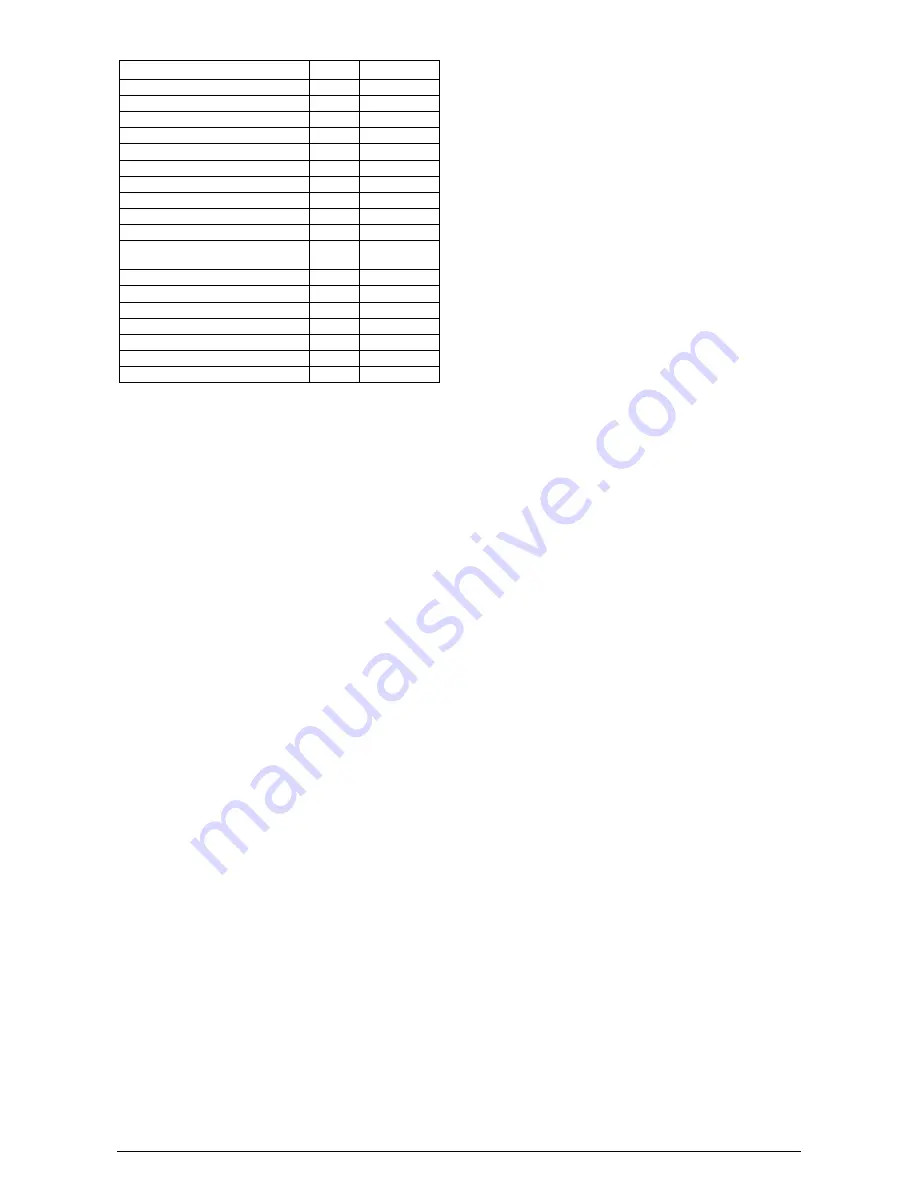

FUNCTION OF I/O

CODE

TYPE OF I/O

Without Function

OFF

Output

Output of Alarm 1

A1

Output

Output of Alarm 2

A2

Output

Output of Alarm 3

A3

Output

Output of Alarm 4

A4

Output

LBD -

Loop break detection

Lbd

Output

Control Output (Relay or Digital Pulse)

CTRL

Output

Automatic / Manual mode selection

mAN

Digital Input

Run / Stop mode selection

RVN

Digital Input

Remote SP selection

RSP

Digital Input

Setpoint profile program HOLD (Freezes

program execution)

KPRG

Digital Input

Setpoint Profile Program 1 selection

PR 1

Digital Input

0 to 20 mA control output selection

(.0.20

Analogical Output

4 to 20 mA control output selection

(.4.20

Analogical Output

Retransmission of PV in 0 to 20 mA

P.0.20

Analogical Output

Retransmission of PV in 4 to 20 mA

P.4.20

Analogical Output

Retransmission of Sp in 0 to 20 mA

S.0.20

Analogical Output

Retransmission of SP in 4 to 20 mA

S.4.20

Analogical Output

Table 2

- Types of functions for the I/O channels

During the configuration of the I/O channels, only the valid options for

each channel will be shown on the display. These functions are

described below:

off

- Without function

The I/O channel programmed with code

off

will not be used by the

controller. Although without function, this channel is available through

the serial communication as digital I/O (command 5 MODBUS).

a1

,

a2

,

a3

,

a4

– Alarm Outputs

The selected channel can be used as output to Alarms 1 to 4.

Defines that the programmed I/O channel acts as alarm outputs.

Available for all the I/O channels.

Lbd

–Loop Break Detector function.

Assigns the output of the Loop Break Detector alarm to an I/O

channel. Available to all I/O channels.

(trL

– PWM Control Output

Defines the I/O channel to be used as the PWM control output (relay

or digital pulse). Available for all the I/O channels. The digital pulse is

available on I/O5 (standard) or on I/O3 and I/O4 (when the DIO

optional is installed). Check the specifications of each channel.

mAn

- Digital Input with Auto/Manual function

Defines the I/O channel as Digital Input with the function of switching

the control mode between

Automatic and Manual

. Available on I/O5

(standard) or on I/O3 and I/O4 (when the DIO optional is installed).

Closed

= Manual control;

Open

= Automatic control

rvn

- Digital Input with

RUN

function

Defines channel as Digital Input with the function of

enabling/disabling the control and alarm outputs (“

RvN

”:

YES

/

no

).

Available for I/O5 or I/O3 and I/O4, when installed.

Closed

= outputs enabled

Open

= control and alarms output shut off

rsp

- Digital Input with Remote SP function

Defines channel as Digital Input with the function of selecting the

remote SP as the control setpoint. Available for I/O5 or I/O3 and

I/O4, when available.

Closed

= remote SP

Open

= uses main SP

kprg

- Digital Input with

Hold Program

function

Defines channel as Digital Input with the function of commanding the

execution of the selected setpoint profile

program

. Available for I/O5

or I/O3 and I/O4, when available.

Closed

= Enables execution of the program

Open

= Interrupts (freezes) execution of the program

Note:

Even when the execution of the program is interrupted, the

control output remains active and controlling the process at the point

(Setpoint) of interruption. The program will resume its normal execution

starting from this same point when the digital input is closed.

Pr 1

- Digital Input with function to Execute Program 1

Defines the IO channel as Digital Input with the function of

commanding the execution of the setpoing profile

program 1.

Available for I/O5 or I/O3 and I/O4, when available.

Useful function for switching between the main

setpoint

and a

secondary one defined by the

program 1

.

Closed

= selects program 1;

Open

= selects main

setpoint

(.0.20

–0-20 mA Control Output

Available for I/O 5 only, defines the channel as a 0-20 mA control

output.

(.4.20 -

4-20 mA Control Output

Defines the channel as a 4-20 mA control output.

P.0.20

– 0-20 mA PV retransmission

Available for I/O 5 only, configures the channel to retransmit the

values of PV in 0-20 mA.

P.4.20

- 4-20 mA PV retransmission

Available for I/O 5 only, configures the channel to retransmit the

values of PV in 4-20 mA.

s.0.20 –

0-20 mA SP (Setpoint) retransmission

Available for I/O 5 only, configures the channel to retransmit the

values of SP in 0-20 mA.

s.4.20 –

4-20 mA SP (Setpoint) retransmission

Available for I/O 5 only, configures the channel to retransmit the

values of SP in 0-20 mA.

CONFIGURATION OF ALARMS

The controller has 4 independent alarms. These alarms can be

configured to operate with nine different functions, as shown in

Table 3

.

off

– Alarms turned

off

.

ierr

– Open Sensor alarms - (

Loop Break

)

The open sensor alarm acts whenever the input sensor is broken or

badly connected.

rs

– Program Event Alarm

Configures the alarm to act in (a) specific segment(s) of the

programs of ramps and baselines to be created by the user.

Rfai1

– Burnt-out Resistance Alarm - (

Heat Break

)

Signals that the heating element has broken up. This alarm function

requires the accessory Current transformer CT1. Details for use of the

option “burnt-out resistance” are found in the specific documentation

that accompanies the product whenever this option is requested.

lo

– Alarm of Absolute Minimum Value

Triggers when the value of measured PV is

below

the value defined

for alarm Setpoint.

ki

– alarm of Absolute Maximum Value

Triggers when the value of measured PV is

above

the value defined

for alarm

Setpoint

.

dif

– Alarm of Differential Value

In this function the parameters “

SPA1

”, “

SPA2

”,”

SPA3

” and “

SPA4

”

represent the Deviation of PV in relation to the SP.

Using the Alarm 1 as example: for Positive SPA1 values, the

Differential alarm triggers when the value of PV is

out

of the range

defined for:

(SP – SPA1) to (SP + SPA1)

For a negative SPA1 value, the Differential alarm triggers when the

value of PV is

within

the range defined above:

difl

– Alarm of Minimum Differential Value

It triggers when the value of PV is below the defined point by:

(SP – SPA1)