5

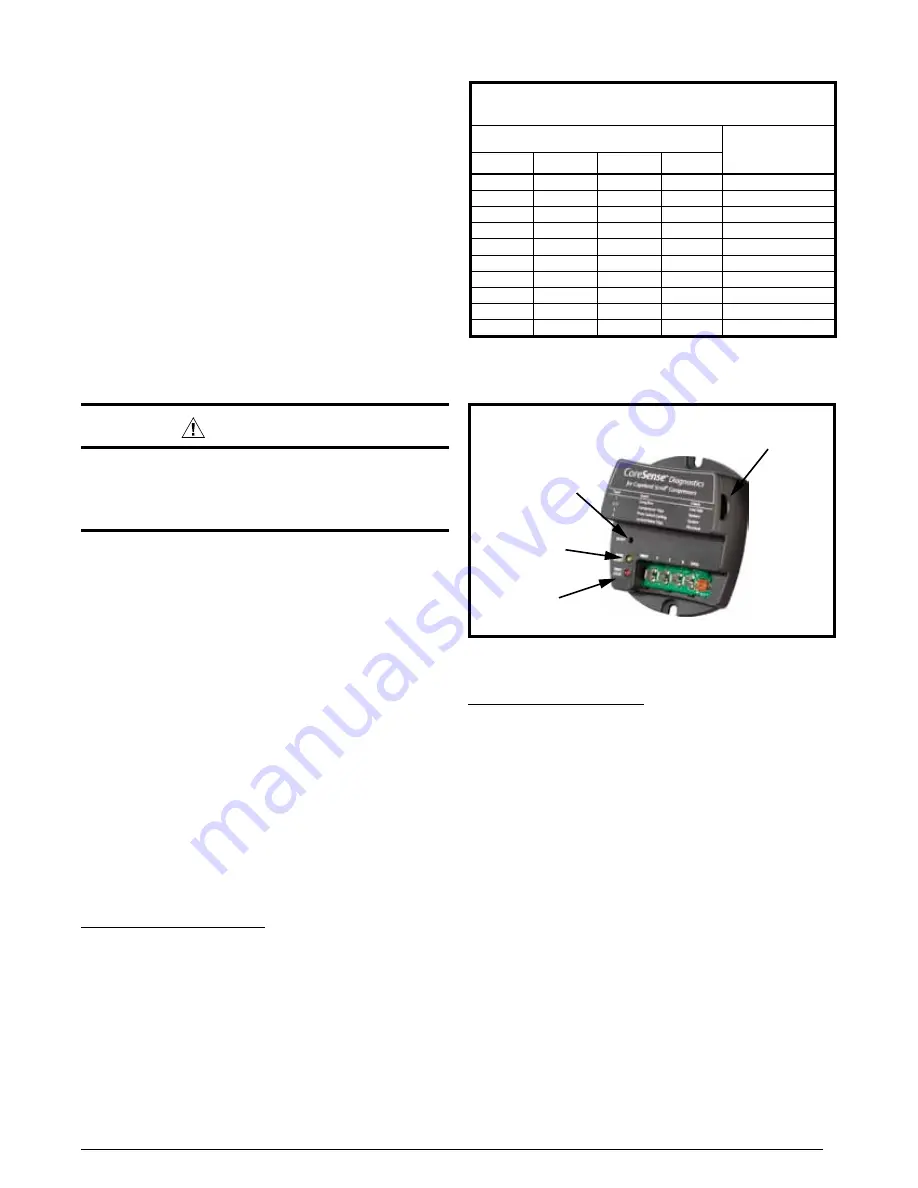

Figure 2

Table 1

• Provide power supply for the unit in accordance with the

unit wiring diagram, and the unit rating plate. Connect

the line-voltage leads to the terminals on the contactor

inside the control compartment.

• Use only copper wire for the line voltage power supply

listed conduit and a conduit connector for connecting

the supply wires to the unit. Use of rain tight conduit is

recommended.

• 208/230 Volt units are shipped from the factory wired

for 230 volt operation. For 208V operation, remove the

lead from the transformer terminal marked 240V and

connect it to the terminal marked 208V.

• Optional equipment requiring connection to the power

or control circuits must be wired in strict accordance of

the NEC (ANSI/NFPA 70), applicable local codes, and

the instructions provided with the equipment.

grounding

Warning:

the unit cabinet must have an uninterrupted or

unbroken electrical ground to minimize personal

injury if an electrical fault should occur. do not

use gas piping as an electrical ground!

This unit must be electrically grounded in accordance

with local codes or, in the absence of local codes, with

the National Electrical Code (ANSI/NFPA 70) or the CSA

C22.1 Electrical Code. Use the grounding lug provided

in the control box for grounding the unit.

coreSense

tm

diagnostics module

(Select models only)

The CoreSense

TM

Diagnostics Module (

) is a

breakthrough innovation for troubleshooting heat pump

and air conditioning system failures. The module installs

easily in the electrical box of the outdoor unit near the

compressor contactor.By using the compressor as

a sensor, CoreSense Diagnostics helps the service

technician more accurately troubleshoot system and

compressor fault conditions.

A flashing LED indicator communicates the ALERT code

and a diagnostic key is also imprinted on the side of the

module to quickly direct the technician to the root cause

of a problem.

Alert identification codes are also listed in

Compressor Protection

The CoreSense

TM

Diagnostics module utilizes proprietary

algorithms to protect the compressor and system from

repeated trips of system pressure controls and the

compressor internal overload. The protection terminal

of the module should be wired in series with the system

low pressure and high pressure cutouts, as well as the

compressor contactor. When the module detects a series

of trips as described below, it will activate a lockout feature

that opens the normally closed protection contacts in

the module, thereby cutting power to the contactor and

shutting off the compressor.

copper Wire SiZe — aWg

(1% Voltage drop)

Supply Wire length-Feet

Supply circuit

ampacity

200

150

100

50

6

8

10

14

15

4

6

8

12

20

4

6

8

10

25

4

4

6

10

30

3

4

6

8

35

3

4

6

8

40

2

3

4

6

45

2

3

4

6

50

2

3

4

6

55

1

2

3

4

60

Wire Size based on N.E.C. for 60° type copper conductors.

table 1. copper Wire Size

Figure 2. coreSense

tm

diagnostics module

Compressor

Common Wire

Reset Button

Trip / Lock

(Red LED)

Run / Alert

(Yellow LED)

Resetting Alert Codes

When the CoreSense

TM

Diagnostics module has detected a

series of adverse conditions that have caused it to lockout

the compressor, and after the issue has been resolved,

it is necessary to manually reset the module in order to

clear the present alert code.

The primary way of clearing the code and resetting the

alert is to press the reset button located on the module.

note:

Pressing the reset will require a pin or a mini

electronics screwdriver. This button must be pressed and

held for a minimum of one second for the module to be

reset. Pressing the reset button clears the immediate lock

code and the seven day operating history. It will not clear

the permanent module history. In the case of the three-

wire module, the codes can be reset or cleared by cycling

power to the module. This can be done by disengaging

the Common (C) terminal. This will not clear the seven

day operating history.