17

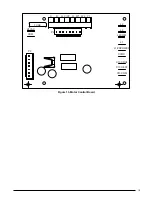

AIRFLOW DATA

Table 2. Airflow Data for B5BM Air Handlers

Dry Coil ESP

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

*24K

A-Cabinet

Low

683

647

607

563

515

463

406

345

Corrected ESP

1

0.00

0.07

0.19

0.30

0.42

0.53

0.65

0.76

Medium

861

823

781

734

682

625

564

498

Corrected ESP

1

0.00

0.00

0.11

0.23

0.36

0.48

0.60

0.72

High

1072

1026

975

920

860

797

730

659

Corrected ESP

1

0.00

0.00

0.00

0.14

0.27

0.40

0.53

0.67

*30K

A-Cabinet

Low

849

825

793

753

704

647

581

508

Corrected ESP

1

0.00

0.04

0.15

0.27

0.38

0.50

0.62

0.74

Medium

1118

1087

1046

997

940

874

799

717

Corrected ESP

1

0.00

0.00

0.04

0.17

0.29

0.42

0.55

0.68

High

1277

1233

1184

1130

1070

1005

935

860

Corrected ESP

1

0.00

0.00

0.00

0.10

0.23

0.36

0.49

0.63

*24/*25K

B-Cabinet

Low

708

690

664

628

584

532

471

401

Corrected ESP

1

0.08

0.19

0.30

0.41

0.53

0.64

0.76

Medium

909

904

886

854

810

753

683

600

Corrected ESP

1

0.10

0.22

0.33

0.46

0.58

0.71

High

1118

1132

1126

1101

1056

992

908

805

Corrected ESP

1

0.09

0.22

0.35

0.49

0.64

*30/*36/*37K

B-Cabinet

Low

953

915

871

821

764

701

631

555

Corrected ESP

1

0.00

0.04

0.16

0.27

0.39

0.51

0.62

0.74

Medium

1265

1232

1188

1133

1067

991

903

805

Corrected ESP

1

0.00

0.00

0.03

0.15

0.28

0.41

0.54

0.68

High

1427

1385

1333

1270

1196

1113

1018

913

Corrected ESP

1

0.00

0.00

0.00

0.09

0.23

0.36

0.50

0.64

*42/*48K

B-Cabinet

Low

1324

1302

1271

1233

1187

1134

1072

1003

Corrected ESP

1

0.00

0.06

0.17

0.27

0.38

0.49

0.61

0.72

Medium

1485

1455

1418

1373

1320

1260

1193

1118

Corrected ESP

1

0.00

0.00

0.13

0.24

0.36

0.47

0.58

0.70

High

1637

1601

1558

1506

1447

1380

1305

1223

Corrected ESP

1

0.00

0.00

0.00

0.21

0.33

0.44

0.56

0.68

*48/*49K

C-Cabinet

Low

1605

1606

1592

1565

1524

1468

1399

1316

Corrected ESP

1

0

0.11

0.21

0.31

0.42

0.52

0.63

0.74

Medium

1977

1939

1890

1830

1758

1675

1580

1474

Corrected ESP

1

0

0

0.18

0.28

0.39

0.50

0.61

0.72

High

2264

2182

2095

2003

1906

1805

1698

1586

Corrected ESP

1

0

0

0

0.26

0.37

0.49

0.60

0.71

*60K

C-Cabinet

Low

1348

1272

1198

1126

1056

988

922

858

Corrected ESP

1

0.00

0.11

0.22

0.33

0.44

0.55

0.65

0.76

Med-Low

1517

1455

1390

1325

1258

1189

1120

1048

Corrected ESP

1

0.00

0.00

0.19

0.30

0.41

0.52

0.63

0.74

Medium

1799

1752

1702

1650

1596

1539

1481

1420

Corrected ESP

1

0.00

0.00

0.00

0.25

0.36

0.47

0.58

0.69

Med-High

1956

1910

1862

1811

1756

1699

1639

1575

Corrected ESP

1

0.00

0.00

0.00

0.22

0.33

0.44

0.55

0.66

High

2146

2099

2050

2000

1948

1894

1839

1783

Corrected ESP

1

0.00

0.00

0.00

0.00

0.29

0.40

0.51

0.62

Notes:

1) Airflow is shown in cfm, +/- 5%.

2) External static pressure (ESP) is shown in inches w.c.

3) See unit nameplate or installation instructions for maximum recommended external static pressure.

Summary of Contents for B5BM

Page 27: ...27...