12

on an outside wall or any other location where its

operation may be adversely affected by radiant heat from

fireplaces, sunlight, or lighting fixtures, and convective

heat from warm air registers or electrical appliances.

Refer to the thermostat manufacturer’s instruction sheet

for detailed mounting and installation information.

• Install the grommet, which is packed with the unit, in

the hole for low-voltage wires. Connect the low-voltage

wiring to the thermostat and the outdoor unit and the

appropriate screw terminal located on the control board.

NOTE: When the low voltage wires are positioned in

this grommet, the grommet will prevent chafing and/or

shorting of the low voltage leads.

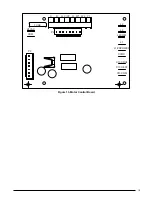

Control Board

The control board in the air handler controls the timing

sequence of the elements. The board is equipped with a 3

second blower on delay and a 15 second blower off delay

in heating and a 40 second blower off delay in cooling.

See Figure 13 (page 19).

Twinning

B5BM air handlers are not supplied with a built in twinning

capability. To connect two air handlers to a common

single stage AC condensing unit or heat pump, a twinning

kit is available for field installation. Please follow the

instructions supplied with the kit.

NOTE: Variable speed air handlers cannot be twinned.

Heater Kits

When electric heat packages with circuit breakers are

field-installed, the circuit breaker may be used as a

disconnecting means in most applications. Reference

the NEC and local codes for disconnect requirements.

If a heater kit is installed:

The B5BM air handler is shipped from the factory without

an electric heater kit installed. If Electric heat is desired,

the H6HK heater kit may be purchased separately and

field installed. Determine the correct size heater kit for your

unit by referring to the list below or the units rating label.

A Cabinet ....................................................... 15Kw max

B Cabinet ....................................................... 20Kw max

C Cabinet ....................................................... 30Kw max

1. Connect the 2 wire plug of the air handler to the mating

2 wire plug of the heater kit.

2. Connect the line voltage leads to the circuit breaker or

terminal block provided.

3. Connect the heater kit plug with the mating receptacle

on the air handler control board.

If a heater kit is not installed:

1. Remove the 2 wire plug of the air handler by cutting

the wires and discarding the plug.

2. Strip the ends of the 2 air handler wires and connect

to the line-voltage leads with the 2 wire nuts provided.

STARTUP & ADjUSTMENTS

WARNING:

The evaporator coil is shipped from the factory

with a nitrogen charge. Use caution when

preparing coils for field connections. If repairs

make it necessary for evacuation and charging,

it should only be attempted by qualified,

trained personnel thoroughly familiar with this

equipment. Some local codes require licensed

installation service personnel to service this

type of equipment. Under no circumstances

should the equipment owner attempt to install

and/or service this equipment. Failure to comply

with this warning could result in equipment

damage, personal injury, or death.

NITROGEN

HEALTH

FLAMMABILITY

REACTIVITY

0 Minimal Hazard

1 Slight Hazard

1

0

0

Before You Start the Unit

Prior to start-up, complete the following inspections:

√

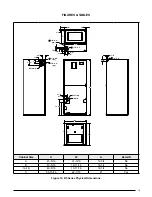

Verify the unit is level and properly located with adequate

clearances for servicing the unit. See Figure 1 (pg 4).

√

Check condensate drain line(s) for proper drainage.

√

Verify the surrounding area and top of the unit is free

from obstructions and debris.

√

Check all duct connections. Make sure the duct work

is adequately sealed to prevent air leakage.

√

Check all coil connections for leaks.

√

Verify that the line voltage power leads are securely

connected and the unit is properly grounded. Make sure

all doors are installed before restoring power to the unit

√

Verify the thermostat is wired correctly. Make sure all

low voltage wires are securely connected to the correct

leads of the low voltage terminal strip.

√

Verify the power supply branch circuit overcurrent

protection is sized properly.

√

Verify filter is properly and securely installed.

IMPORTANT: Before starting the unit, install the initial

charge on units that are factory shipped with a nitrogen

holding charge:

1. Read all installation instructions first.

2. Purge the nitrogen holding charge.

3. Evacuate the unit to 350 - 500 microns.

4. Allow the unit to remain under vacuum for at least 30

minutes.

Summary of Contents for B5BM

Page 27: ...27...