1-Nov-2021

Page 20

001200MAN-09

Ductwork

Zoning

Zoning can be done with heat pumps that have 2-stage

compressors, but only to a limited extent. It is recommended

that no zone be less than 1/3 the total area, to avoid problems of

high airflow and noise through one zone or safety control trips

due to capacity mismatch between heat pump and zones.

The airflow can be reduced by 15% by making a dry con-

tact across

AR1

and

AR2

on the thermostat terminal strip in the

heat pump’s electrical box, as show in

Wiring

chapter.

When only one zone of 50% or less is calling for heating or

cooling, the compressor should be limited to

stage 1

operation

by the zone controller by sending only a

Y1

(without Y2) control

signal. Stage 1 corresponds to ~67% compressor capacity and

~80% airflow.

Refer to airflow tables in the

Model Specific Information

chapter for airflows with the various reductions.

Duct Systems - General

Ductwork layout for a heat pump will differ from traditional

hot air furnace design in the number of leads and size of main

trunks required. Air temperature leaving the heat pump is

normally

95º -105ºF (35-40ºC)

, much cooler than that of a

conventional fossil fuel furnace. To compensate for this, larger

volumes of lower temperature air must be moved and

consequently duct sizing must be able to accommodate the

greater airflow without creating a high static pressure or high

velocity at the floor diffusers.

A duct system capable of supplying the required airflow is

of utmost importance. Maritime Geothermal Ltd. recommends

that the external static pressure from the duct system be kept

below 0.2 inches of water total. In some instances the number

of floor diffusers will actually double when compared to the

number that would be used for a hot air oil-fired furnace. Refer

to following tables.

1. Generally allow

100 cfm

for each floor grill.

2. All leads to the grills should be 6'' in diameter (28sq.in. each).

3. The main hot air trunks should be at least 75% of the square

surface area of leads being fed at any given point.

4. Return air grills should have a minimum of the same total

square surface area as the total of the supply grills.

5. The square surface area of the return trunks should equal

the square surface area of the grills being handled at any

given point along the trunk.

It is

VERY IMPORTANT

that all turns in both the supply

trunks and the return trunks be made with

TURNING RADII

. Air

act like a fluid and, just like water, pressure drop is increased

when air is forced to change direction rapidly around a sharp or

irregular corner.

It is recommended that flexible collars be used to connect

the main trunks to the heat pump. This helps prevent any vibra-

tions from travelling down the ductwork. If a plenum heater is

installed, the collar should be at least 12” away from the heater

elements.

If desired, the first 5-10 feet of the main supply trunks can

be insulated internally with acoustical duct insulation to further

inhibit any noise from the unit from travelling down the ductwork.

If a plenum heater is installed, insulation should not be placed

within 12” of the heater elements.

Duct Systems - Grill Layout

Most forced air heating systems in homes have the floor

grills placed around the perimeter of the room. Supply grills

should be placed under a window when possible to help prevent

condensation on the window. As mentioned in the previous sub

-section, supply grill leads should be 6'' in diameter (28 square

inches each) to allow

100 cfm

of airflow.

In a typical new construction, there should be one supply

grill for every 100 square feet of area in the room. When rooms

require more than one grill, they should be placed in a manner

that promotes even heat distribution, such as one at each end of

the room. It is always a good idea to place a damper in each

grill supply or place adjustable grills so that any imbalances in

the heat distribution can be corrected.

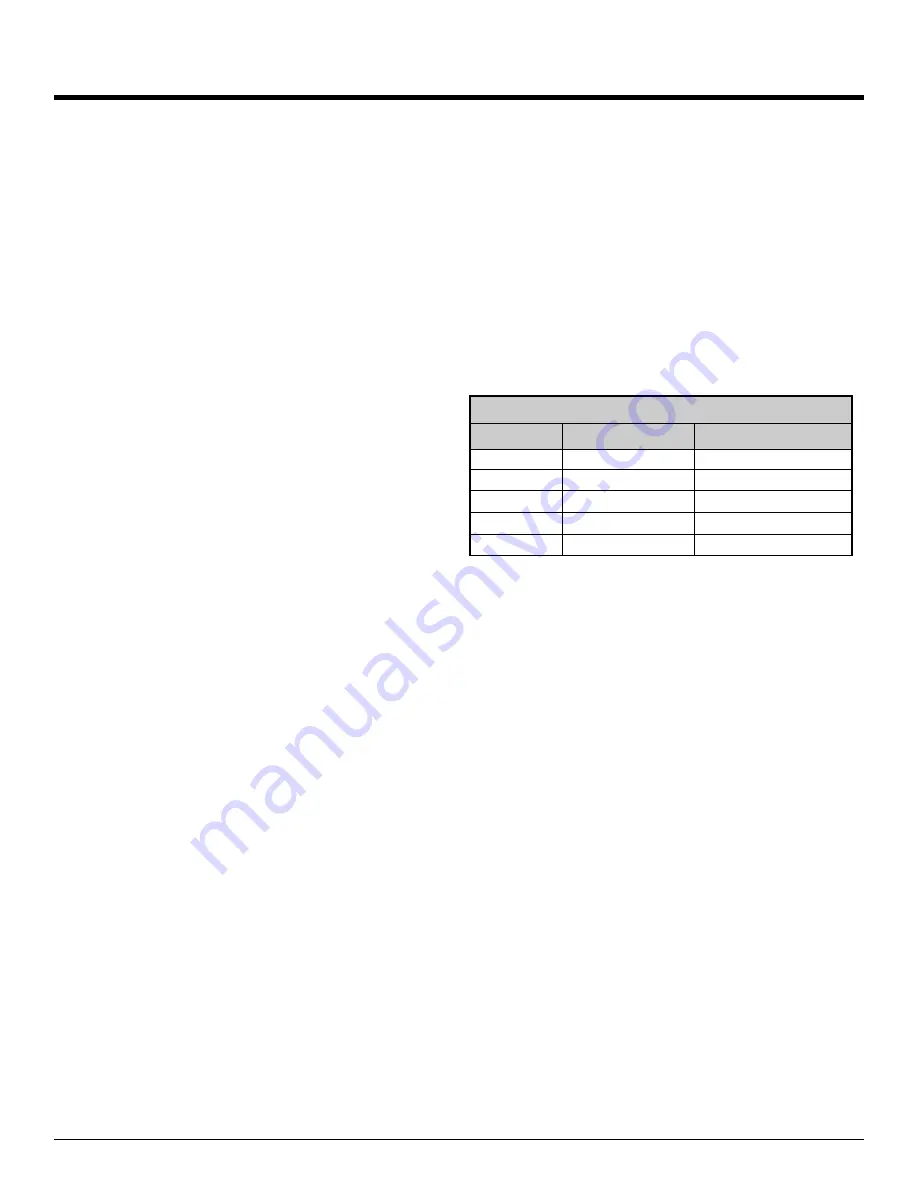

The total number of supply grills available is based on the

heat pump nominal airflow. The table

shows the number of

grills recommended per heat pump size.

Return grills should be mounted on the floor. At minimum

they should be the same size as the supply grill,

it is highly rec-

ommended that they be 25% to 50% larger than the total

supply.

They should be placed opposite the supply grills

when possible to ensure distribution across the room. For

rooms requiring more than one supply grill, it may be possible to

use one larger return grill if it can be centrally positioned oppo-

site of the supply grills, however it is preferred to have one re-

turn for each supply to optimize heat distribution across the

room.

Thermostat Location

Most homes are a single ducted air zone with one thermo-

stat. The thermostat should be centrally located within the

home, typically on the main floor. It should be placed away from

any supply grills, and should not be positioned directly above a

return grill. Most installations have the thermostat located in a

hallway, or on the inner wall of the living room. It should be not-

ed that most homes do not have any supply ducts in the hall-

way. This can lead to a temperature lag at the thermostat if

there is very little air movement in the hallway, causing the

home to be warmer than indicated by the thermostat.

Plenum Heater

The plenum heater will be usually installed inside the heat

pump, as described in the

Installation Basics

section. If the

blower is installed in the side discharge position, the plenum

heater will be installed in the discharge ductwork outside the

unit, at least 12” away from any flexible duct collars. There is an

accessory plenum heater with a wider cage profile available that

is more suitable for duct installation.

TABLE 10 - Heat Pump Size vs. Hot Air Grills

Model

Size (tons)

# of Grills (@100 cfm)

45

3

12

55

4

15

65

5

19

75

6

21

80

6.5

23

Summary of Contents for R-45

Page 11: ...1 Nov 2021 Page 11 001200MAN 09...

Page 15: ...1 Nov 2021 Page 15 001200MAN 09...

Page 16: ...1 Nov 2021 Page 16 001200MAN 09...

Page 18: ...1 Nov 2021 Page 18 001200MAN 09...

Page 19: ...1 Nov 2021 Page 19 001200MAN 09...

Page 21: ...1 Nov 2021 Page 21 001200MAN 09...

Page 25: ...1 Nov 2021 Page 25 001200MAN 09...

Page 26: ...1 Nov 2021 Page 26 001200MAN 09...

Page 27: ...1 Nov 2021 Page 27 001200MAN 09...

Page 28: ...1 Nov 2021 Page 28 001200MAN 09...

Page 29: ...1 Nov 2021 Page 29 001200MAN 09...

Page 33: ...1 Nov 2021 Page 33 001200MAN 09...

Page 34: ...1 Nov 2021 Page 34 001200MAN 09...

Page 35: ...1 Nov 2021 Page 35 001200MAN 09...

Page 63: ...1 Nov 2021 Page 63 001200MAN 09 Wiring Diagram 208 230 1 60...

Page 64: ...1 Nov 2021 Page 64 001200MAN 09 Electrical Box Layout R 45 75 208 230 1 60...

Page 65: ...1 Nov 2021 Page 65 001200MAN 09 Electrical Box Layout R 80 208 230 1 60...

Page 66: ...1 Nov 2021 Page 66 001200MAN 09 Electrical Box Layout RH 45 75 208 230 1 60...

Page 67: ...1 Nov 2021 Page 67 001200MAN 09 Wiring Diagram 208 3 60...

Page 68: ...1 Nov 2021 Page 68 001200MAN 09 Electrical Box Layout R 45 75 208 3 60...

Page 69: ...1 Nov 2021 Page 69 001200MAN 09 Electrical Box Layout R 80 208 3 60...

Page 70: ...1 Nov 2021 Page 70 001200MAN 09 Electrical Box Layout RH 45 75 208 3 60...

Page 71: ...1 Nov 2021 Page 71 001200MAN 09 Wiring Diagram 265 277 1 60...

Page 72: ...1 Nov 2021 Page 72 001200MAN 09 Electrical Box Layout R 45 75 265 277 1 60...

Page 73: ...1 Nov 2021 Page 73 001200MAN 09 Electrical Box Layout R 80 265 277 1 60...

Page 74: ...1 Nov 2021 Page 74 001200MAN 09 Electrical Box Layout RH 45 75 265 277 1 60...

Page 75: ...1 Nov 2021 Page 75 001200MAN 09 Wiring Diagram 460 3 60...

Page 76: ...1 Nov 2021 Page 76 001200MAN 09 Electrical Box Layout R 25 75 460 3 60...

Page 77: ...1 Nov 2021 Page 77 001200MAN 09 Electrical Box Layout R 80 460 3 60...

Page 78: ...1 Nov 2021 Page 78 001200MAN 09 Electrical Box Layout RH 25 75 460 3 60...

Page 79: ...1 Nov 2021 Page 79 001200MAN 09...

Page 80: ...1 Nov 2021 Page 80 001200MAN 09...

Page 81: ...1 Nov 2021 Page 81 001200MAN 09 Dimensions R 45 Left Return...

Page 82: ...1 Nov 2021 Page 82 001200MAN 09 Dimensions R 45 Right Return...

Page 83: ...1 Nov 2021 Page 83 001200MAN 09 Dimensions R 55 65 75 Left Return...

Page 84: ...1 Nov 2021 Page 84 001200MAN 09 Dimensions R 55 65 75 Right Return...

Page 85: ...1 Nov 2021 Page 85 001200MAN 09 Dimensions R 80 Left Return...

Page 86: ...1 Nov 2021 Page 86 001200MAN 09 Dimensions R 80 Right Return...

Page 87: ...1 Nov 2021 Page 87 001200MAN 09 Dimensions RH 45 Left Return...

Page 88: ...1 Nov 2021 Page 88 001200MAN 09 Dimensions RH 45 Right Return...

Page 89: ...1 Nov 2021 Page 89 001200MAN 09 Dimensions RH 55 65 75 Left Return...

Page 90: ...1 Nov 2021 Page 90 001200MAN 09 Dimensions RH 55 65 75 Right Return...