17

1. Power display: 10 grids indicate 100% charge, each grid represents 10% charge, every 10%

discharge with power out of one grid, if the remaining charge is less than 20%, the grids on the

display screen flashes. When the battery is charged to the recovery voltage of the indicator, the

display screen will show full recovery charge grids. Every time you turn on the display, the record/

memory is available;

2. Hour-meter display: the working time of the truck is recorded in unit (hour) with accuracy of 0.1 hour.

Every time you turn on the display, the record/ memory is available;

3. Fault code display: it consists of two parts. One is the wrench symbol: wrench symbol showed on

the screen indicates the fault of the truck, it will not be on the screen without fault; The other part is

fault code: when the wrench symbol is displayed on the screen, the original position of the

hour-meter displays the fault code. See the table of fault codes for details (Note: only the fault on

the tiller is displayed, the analog signal of the controller is displayed by its own indicator light);

4. Turtle speed display: the turtle symbol is normally off. Press the turtle speed button on the tiller, then

the turtle symbol will display on the screen and the truck is in slow speed;

5. Timing hourglass display: when the hour timing function of the tiller is activated, the hourglass

symbol displays on the screen, if not, the hourglass symbol will not display.

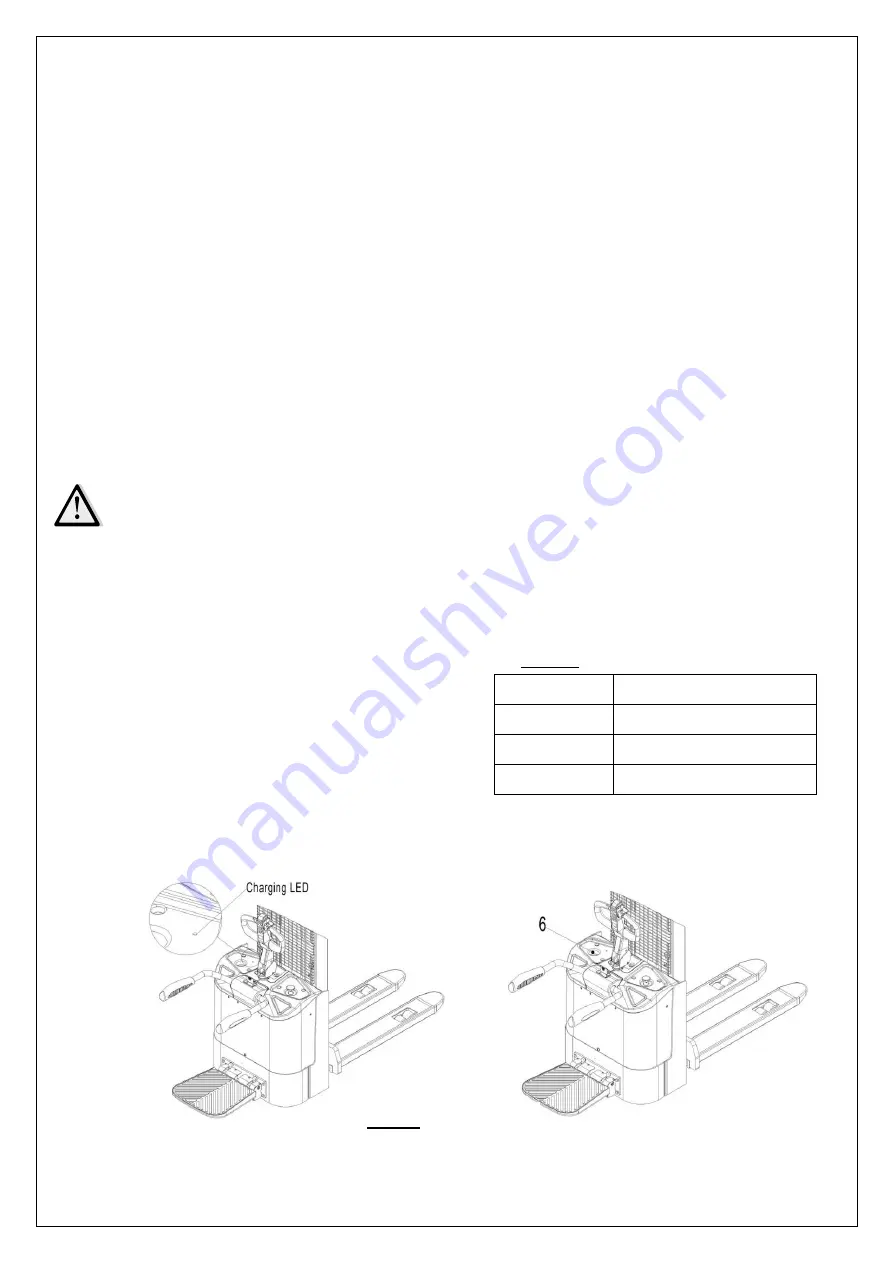

c. Charging

•

Before using the charger, please fully understand the instructions of the charger

instructions.

•

Always follow these instructions.

•

The room, where you are charging must be ventilated.

•

The exactly charge status can be only checked from the discharge indicator. To

control the status, the charging must be interrupted and the truck must be started.

Table 3: LED-Status

LED- signal

Function

Red

Battery discharged

Orange

Charger or battery failure

Green

Fully charged

Fig. 14: Charging

Park the truck at a dedicated secured area with a

dedicated power supply.

Lower the forks and remove the load;

Switch the truck off, the charger starts charging the

battery if the charger plug (Fig.1, 6) is connected to the

main power supply.

When charging is finished, disconnect the plug (Fig. 13)

from the power supply and place it in the designated

area.