NOAQ BW102 1.0 201201

2 (8)

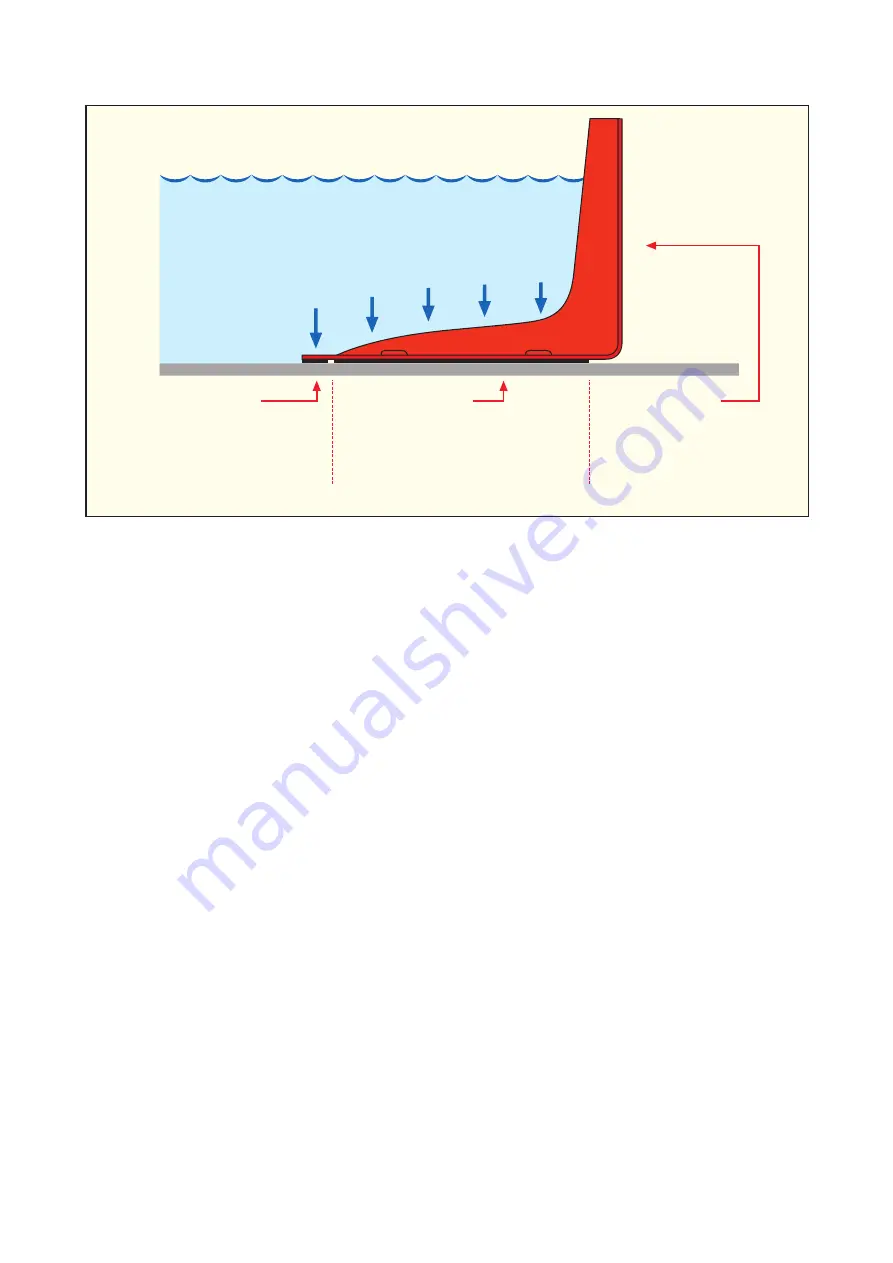

Each box consists of a damming part (the rear wall), an anchoring part (the horizontal section

that rests on the ground) and a sealing part (the front edge of the horizontal section). Sealing

strips of cellular plastic are fitted under the front and side edges. Each box is also fitted with

three cellular rubber soles to create a good grip on the road.

A boxwall is built up by snapping boxes one at a time onto the previous one. The easiest

way is to work from left to right (viewed from the dry side). You should avoid working from

two directions, as it is difficult to make the two wall sections meet at exactly the same point.

As with all mobile flood barriers you need to count on a certain leakage. This can be minimized

by covering the barrier with a plastic liner. But water is also leaking through the ground under

the barrier. Water may also come to the protected area as rain and through brooks which have

been cut off by the barrier itself.

Therefore one or more pumps must always be put on the

intended dry side of the barrier.

Sealing part

Beneath the front edge of

the boxwall is a sealing strip

made of cellular rubber. This

keeps the leakage of water

at the bottom to a minimum.

Anchoring part

The anchoring force is proportional to

the difference in water pressure between

the upper and lower side of the boxwall.

A system of drainage channels on the

lower side diverts the leaking water, so

that no counter pressure arises

Damming part

The rear wall dams the flood

water. The water’s pressure

is absorbed by a three large

bulges, which also act as

drainage channels.

This is how a NOAQ Boxwall works

The base section of the boxwall is pressed firmly against

the ground by the weight of the flood water. There are

three cellular rubber soles on the underside to provide

a reliable grip on the road.