4

INSTRUCTIONS FOR

THIS TOOL

About Your Tool

WARNING

●

Wear protective glasses and a dustproof mask.

operation generates chips and dust particles, etc.

which may cause eye and/or respiratory injury:

Always use PPE (Personal Protective Equipment)

for eye and respiratory protection.

●

Wear vibration reducing and shock absorbing

gloves.

This is a power tool utilizing vibration. Wear vibration

reducing and shock absorbing gloves. When your

hands, fingers, arms, etc. feel discomfort during

operations, immediately stop your work. Long hour

operation should be prohibited, for it may cause

Vibration - Induced disorder.

●

Always wear suitable hearing protection.

The tool generates loud noise. Always use ear plugs

for hearing protection. Take necessary measures to

comply with the local regulatory requirements and

laws with regard to noise level, or do better.

●

Do not operate tool at no load.

Do not operate the tool at no load: It may not only

cause damage to the tool but also may cause

chisels to fracture and fly out, possibly resulting in

unexpected accident.

●

Be sure to keep hands clear of chisel edge.

●

Fix the chisel firmly. If the chisel is not fixed

firmly , it may jump out and cause injury

1. USAGE

This tool is for chipping work pieces with a chisel.

2. CHECK THE CONTENTS OF THE PACKAGE

Check the contents and make sure that the tool

does not have any damage which may have

occurred during transportation. The contents should

correspond to the list as follows. In case of damage/

missing parts, please contact the sales agent from

whom you purchased the tool.

ACH-16

Package Contents

Qty

check

ACH-16

1

Flat Chisel 20×120

1

Bushing R3/8×NPT3/8

1

Hose Nipple R3/8×3/8

1

Instruction Manual

1

Declaration of Conformity

1

Caution for Use

1

CH-24

Package Contents

Qty

check

CH-24

1

Curved Flat Chisel 25×155

1

Bushing R3/8×NPT3/8

1

Hose Nipple R3/8×3/8

1

Instruction Manual

1

Declaration of Conformity

1

Caution for Use

1

3. AIR SUPPLY

3-1. Air Pressure

Adjust air pressure with the air regulator to the level

appropriate for the pneumatic tool used.

Air pressure that is too low will fails the tool to

operate at full capacity

Air pressure that is too high may cause damage to

the tool.

3-2. Air Line

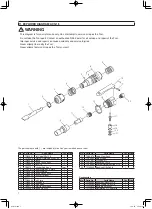

(Fig.1)

Use a 9.5mm (3/8”) I.D. connecting hose between

the compressor and the tool.

Drained water, etc., if flown into the tool, could

cause tool failure. Install an air filter, bsetween the

compressor and the tool.

Air Regulator

Oiler

Air Filter

Compressor

Lubrication

Tool

9.5mm (3/8”) I.D.

Hose

Cupla

Fig. 1

3-3. Lubrication

Install an oiler between the compressor and the tool.

Use the machine oil ISO VG-10. Failure to lubricate

as required may result in damage to the tool. Use of

oil that is too thick will reduce the performance of the

tool.

ACH-16.indd 4

14.4.23 1:56:15 PM