B. Operation

After the engine has started, allow approximately 30 seconds for the engine to "warm up" then advance the throttle to

operating speed.

Engage the clutch by pulling up on the switch lever (mounted on the handle).

Lower the burnishing head to the floor while moving the machine forward slowly.

CAUTION! DO NOT RUN THE MACHINE WITHOUT MOVING THE MACHINE. IF ALLOWED TO RUN IN ONE SPOT

DAMAGE TO THE FLOOR MAY OCCUR.

To stop burnishing, push down on handle raising the burnishing head off the floor and release the clutch switch lever.

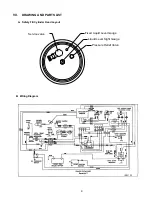

NOTE: This machine is equipped with SmartAir emission monitoring system and catalytic muffler.

Upon starting the engine, the GREEN LED will flash for 3 minutes during a warm-up period. After that time it will be on

steady unless a warning is being signaled. If the carbon monoxide in the exhaust is approaching a hazardous level the green

light will go out and the RED LED will start flashing. When the red light goes to STEADY RED it will shut the machine down

within 1 minute.

WARNING! Catalytic mufflers require a few minutes to warm up before effectively removing harmful emissions. Make

sure of proper ventilation during this warm-up period!

C. Idling and Stopping the Machine

If for any reason the machine needs to idle for short periods (less than 3 minutes), simply raise the burnishing head and

release the clutch switch and move the throttle to the SLOW position.

The SmartAir system will not allow the engine to

idle unnecessarily. After 2 minutes the GREEN LED will start flashing. In another 1 minute the engine will shut

down.

To stop the engine close the service valve on the fuel cylinder by turning it clockwise. (The engine will stop when the fuel in

the lines is used up.)

After the engine stops, turn the key switch to "OFF" position.

Failing to turn the key OFF may

drain the battery.

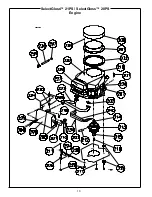

D. Installing/Changing Burnishing Pad

1. With engine OFF turn the machine over on the

RIGHT

side (the starter side). This can be accomplished easily by

pushing down on the right handle grip with some force while the machine is tilted back.

2. Remove centering device (if used) and carefully pull old pad off the velcro pad holding material.

3.

CAREFULLY INSPECT THE PAD HOLDER FOR CRACKS OR DAMAGE!

Replace if necessary.

NOTE:

A damaged pad holder rotating at high speeds may be an extreme hazard if it should come apart.

4. Pull center from new pad, center pad on pad holder and secure with centering device (if used) or tuck the center under

the plastic center ring.

5. Press pad onto velcro.

6. Return machine to upright position.

E. Storage

Only authorized, trained personnel should have access to propane cylinders and machines.

1.

Remove propane fuel cylinder when not in use and store it outside in a storage cage in accordance with NFPA

Section 5 or Subsection 9.5.2 of CAN/CGA B149.2. Do not release or bleed propane inside of the building.

Please consult your local Fire Marshal to insure that you are in compliance with local fire codes.

2. Store machine away from objects that may fall and damage it.

3. Never store machine or fuel cylinders near an open flame or heat producing devices.

4. Make sure machine is cleaned properly before storing.

5. Never store machines with cylinders installed, or spare cylinders, in an enclosed van or trailer.

F. Transportation

When transporting a propane powered burnisher with the fuel cylinder installed, the cylinder should be securely fastened

with the service valve closed and the machine should be secured in the vehicle. Any propane fuel cylinders not installed on a

machine should be securely fastened to avoid movement and damage. The service valves should be closed. Never store

machines with cylinders installed, or spare cylinders, in an enclosed van or trailer.

It is a good practice to check propane cylinders for overfilling before transporting them. If overfilled, correct before loading

them in the vehicle by venting the excess propane outside in a safe area using the fixed liquid level gauge.

3