MAINTENANCE

Operation if Breaker

Assembly Procedures

1. Install the screw case into the drive housing and tighten with nuts for attaching the screw case.

2. Install hopper onto the screw case and tighten with bolts for attaching the clay hopper.

3. Install nozzle onto the screw and tighten with nuts for attaching the nozzle.

4. Pull the lever down, plug the power card into the outlet, and switch the power on. Check for unusual

sounds. Recheck assembly if necessary.

The breaker will not shut off under normal use. If you forcibly push a large amount of clay, or hard clay,

into the hopper it will cause the breaker to shut off the pug mill. In the event that the breaker shuts off the

pug mill will stop. In this case press the breaker switch inward, the breaker switch is under a waterproof

cap. Do not remove the water cap. Press the breaker with the cap in place.

Precautions

*Do not operate any switches with wet hands.

*Do not insert your hands into any pug mill opening.

Trail Operation

1. Plug the power cord into the outlet.

2. Do not set anything into the clay hopper, pull the lever down, switch the power on,

and then allow the unit to run for a short time.

3. Check if the pug mill has any vibration, rattles, or unusual sounds (If none then

proceed to the section on operation).

4. Switch the power off and unplug the unit.

5. Make adjustments to level and position the pug mill.

6. Return to step one.

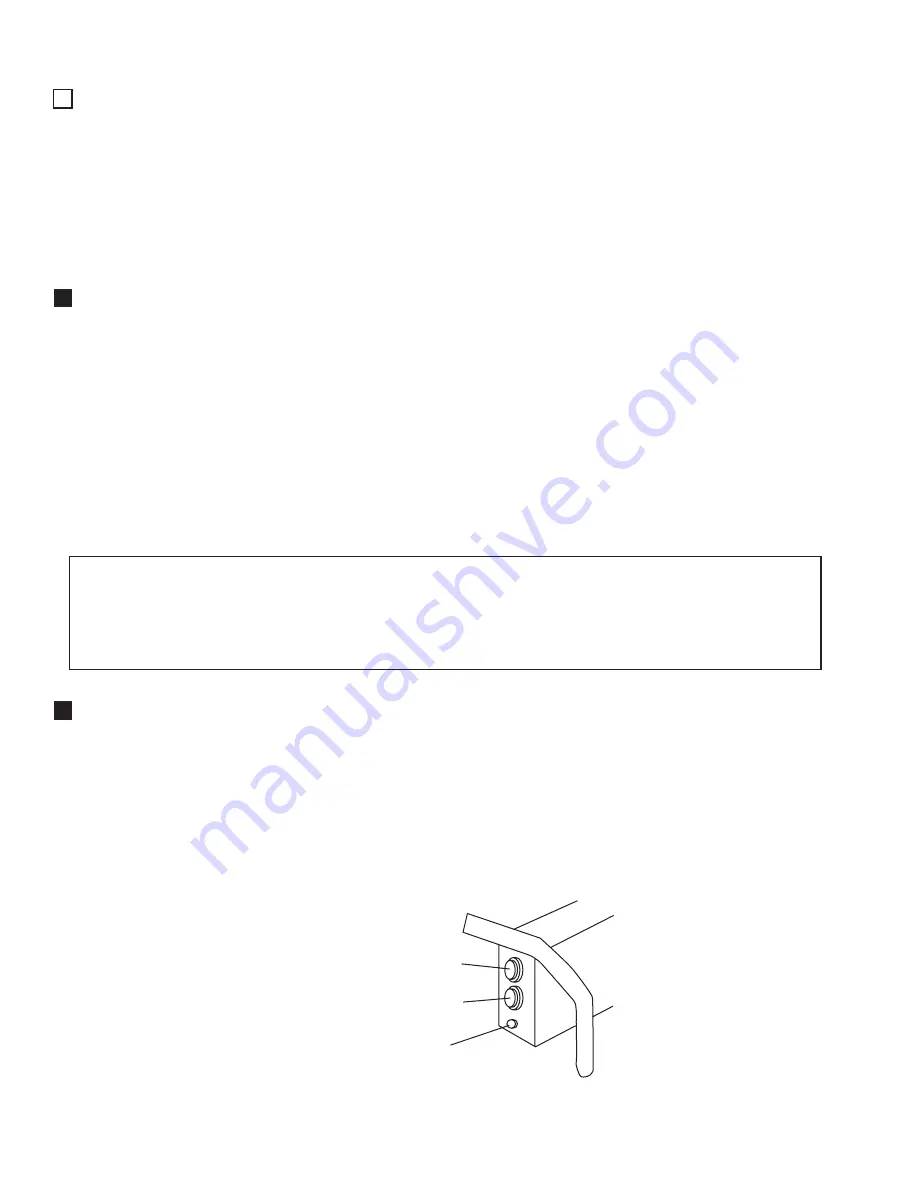

SWITCH

ON (START)

OFF (STOP)

BREAKER