17

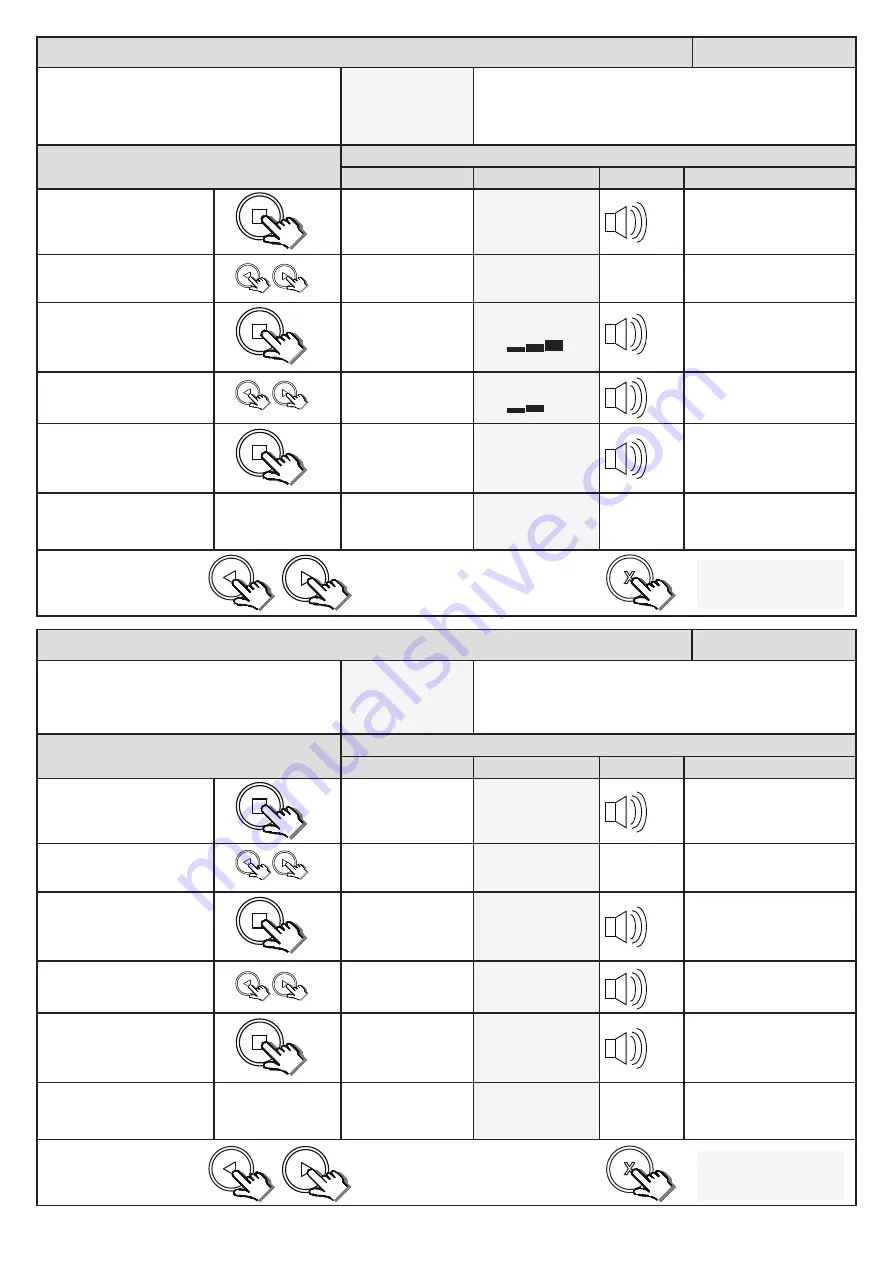

Selecting a safety level.

Overload Setting

From Standby status

- “Selected” mode -

- Standby

This adjusts the force level, over and above the nominal

barrier resistance, needed to trigger the safety overload

routines. Level 1 being the most sensitive and 8 being the

least sensitive. The factory default is level 3.

Action

Response

Description

Display

Buzzer

Barrier

To enter the program menu.

Press and hold the

button

until buzzer beeps.

Display and buzzer

confirms.

Programming menu

<or> for options

Scroll < or > to select the

runtime setup option.

Display scrolls

through options.

Overload Setting

<

= change >

With “Overload Setting” on

the display, press and release

.

Display shows current

option status.

Overload Setting

< >

Scroll < or > to the required

setting.

Display changes

respectively.

Overload Setting

< >

With required setting

displayed, press and release

.

Display briefly shows

the new setting is

saved.

Overload Setting

Saved = 2

After display confirms new

setting.

Overload Setting

<

= change >

Display returns to

programming menu

options list.

Overload Setting

<

= change >

x2

x1

x1

Scroll left or right to next

program option.

OR

“Selected” mode

- Standby

EXIT back to standby

status

x2

Safety infra-red beams setup.

Beam Setup.

From Standby status

- “Selected” mode -

- Standby

Use this option to enable the safety beam circuit for use in

standard BT mode. (See page 20)

Action

Response

Description

Display

Buzzer

Barrier

To enter the program menu.

Press and hold the

button

until buzzer beeps.

Display and buzzer

confirms.

Programming menu

<or> for options

Scroll < or > to select the

beam setup option.

Display scrolls

through options.

Beam Setup

<

= change >

With “Beam Setup” on the

display, press and release

.

Display shows current

option status.

Beam Setup

Disabled

Scroll < or > to toggle

between “Enabled” and

“Disabled”.

Display changes

respectively.

Beam Setup

Enabled

With required setting

displayed, press and release

.

Display briefly shows

the new setting is

saved.

Beam Setup

Enabled Saved

After display confirms new

setting.

Beam Setup

Enabled Saved

Display returns to

programming menu

options list.

Beam Setup

<

= change >

x2

x1

x1

Scroll left or right to next

program option.

OR

“Selected” mode

- Standby

EXIT back to standby

status

x2

Summary of Contents for WIDE L

Page 12: ...12 Adjusting the end stops...