32

12.3 - Communication buses

On the Slave operator, select Function -> Adv. Settings -> Remote Mst. Slv.

Then select On -> Slave. The red LED associated with the Master/Slave

connector will illuminate.

The Master/Slave pair is now configured. The Slave gate operator will perform

identical open/close/stop functions in tandem with the Master gate operator.

12.4 - Programming the plug-in receiver and remote controls

Nice Plug in Receiver:

The Nice 433Plug-In Receiver provides up to 15

channels for specific control of individual gate functions. The receiver includes

built-in programming functions for adding or removing Nice wireless remote

controls to/from a gate installation. The following procedures detail the steps

to assign a remote control, add a new remote control, delete a single remote

control, or remove all remote controls from the receiver memory.

Programming the Nice 2-Button or 4-Button Remote Control with the

Nice Plug-In Receiver.

These procedures apply to the Nice wireless remote control. These procedures

assign factory default controls automatically to the remote control.

1.

Have a functioning Nice 2-button or 4-button remote control with a battery

installed prior to programming the remote control.

2.

Press and hold the button on the side of the Nice receiver until the led

illuminates green on the Nice receiver, then release the button.

3.

Within 10 seconds, press and hold any key on the Nice remote control until

the led in the Nice receiver blinks green 3 times, indicating that the Nice is

programmed to control the receiver.

4.

After the led on the Nice receiver blinks green 3 times, another 10 second

interval is started to program another Nice remote control if desired. Repeat

step 3 to program the additional Nice remote control. Step 3 may be repeated

as many times as necessary to program all available Nice remote controls.

5.

Verify that the Nice remote control(s) can control the gate by pressing one or

more buttons individually on the remote control(s).

Add new remote control to the Nice Plug-In Receiver

A Nice remote control that has been programmed to control a Nice receiver

may be used to create other Nice remote controls for the same receiver. This

procedure needs to be performed within 10 to 20m (30 to 60 feet) of the Nice

receiver, but the Nice receiver does not need to be physically accessed.

1.

Press and hold any button on the non programmed Nice remote control for

at least 5 seconds, then release the button, taking note of the button that was

pressed.

2.

Press the same button on the programmed Nice remote control three times.

3.

Press the same button in step 1 on the non programmed Nice remote control

and release.

4.

It is recommended to test the new copy of the Nice remote control with the

assigned gate controller.

NOTE: This procedure will affect all Nice receivers within radio range.

Deleting a Single Nice Remote Control from the Nice Plug-In Receiver

Memory

A Nice remote control that has been programmed to control a Nice receiver may

be removed from the Nice receiver memory without affecting other assigned

remote controls. This procedure needs to be performed at the Nice Plug-In

Receiver with the affected Nice remote control.

1.

Press and hold the button on the side of the Nice receiver until the led on

the Nice receiver illuminates green and keep the button pressed. The led will

illuminate after approximately 4 seconds.

2.

Press and hold any button on the Nice remote control until the led on the Nice

receiver blinks 5 green flashes

3.

Release the button on the side of the Nice receiver.

4.

It is recommended to verify that the non programmed Nice remote control no

longer controls the gate.

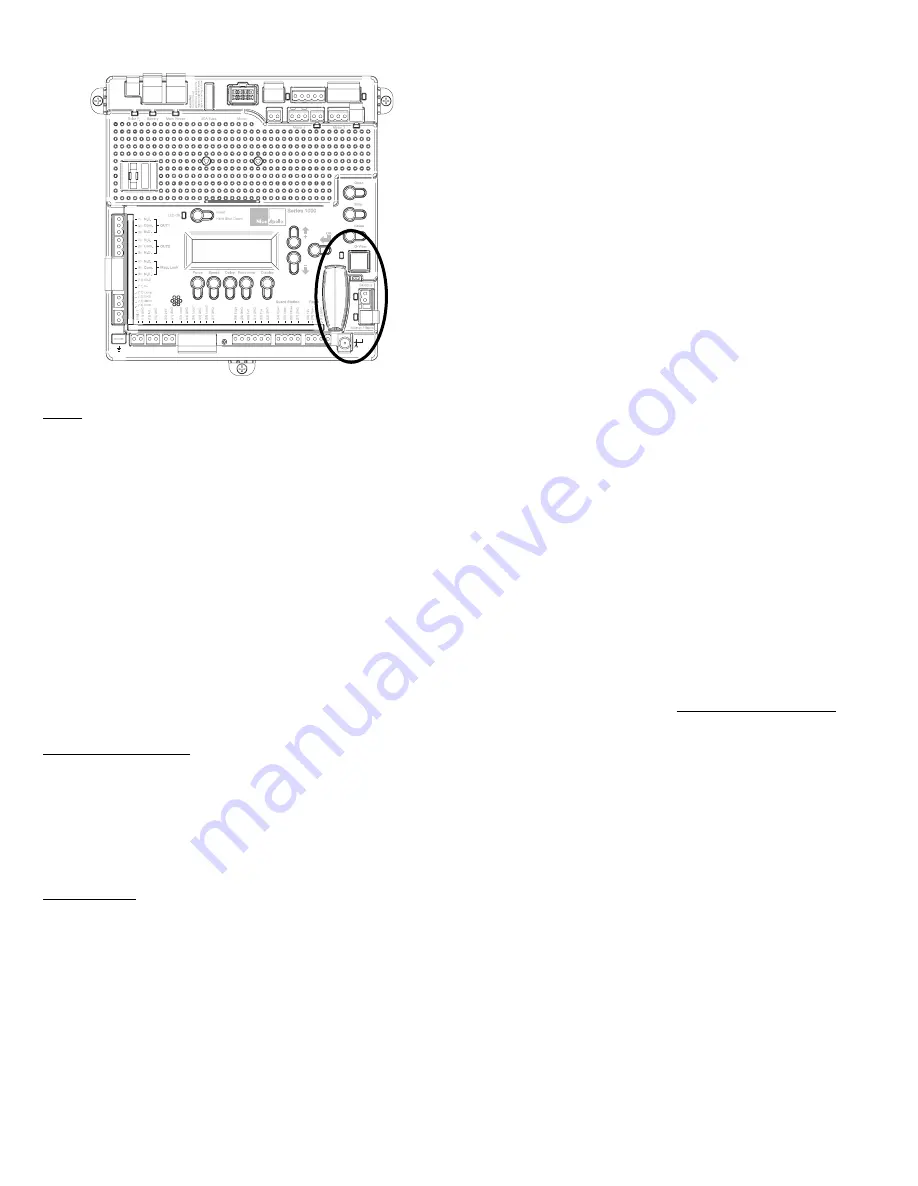

Figure - COMMUNICATION BUSES

OVIEW

Programming and diagnostic unit which connects directly to the gate

controller and is part of the Nice “Opera” control system. The unit can be

used in “stand-alone” mode via its front-panel keypad, or it may be accessed

via a Bluetooth or cellular-enabled PDA, PC, or Smartphone when used with

the

O-View Software Suite. This unit, when matched with the OVIEW Bluetooth

or

GSM modules, enables remote control and management of the gate

controller. Remote control functions include most of the programming

functions that are available at the front panel LCD on the control board as

well as software updates.

OVBT:

Bluetooth module for OVIEW and the “O-View Software Suite”

application for PC, PDA, or Smartphone for localized wireless control of the

gate controller.

OVBTGSM:

Combination GSM and Bluetooth module that plugs into the

OVIEW and provides cellular phone access through the “O-View Software

Suite” application for PC, PDA, or Smartphone, for wireless local, national,

and international controller of the gate controller.

O-VIEW Software Suite:

Provides desktop or Smartphone level control of

the gate controller. Other benefits include software updates that can be made

as new versions of software are made available.

BLUEBUS ACCESSORIES

MOTB:

Moon Touch programmable keypad with secure codes (up to 9 digits

per code if required) to control gate opening and closing. Connects to the

2-wire BlueBUS connector with inexpensive unshielded twisted-pair wire.

MOFB:

Photocell transmitter and receiver pair that connects to the 2-wire

BlueBUS connector with inexpensive unshielded twisted-pair wire and is a

non-contact sensor for entrapment protection as specified in UL325, Section

31.1 “General Entrapment Protection Provisions”.

MASTER/SLAVE - ONLY USED IN 24V COMMERCIAL OPERATORS

The gate operator includes a two-pin connector designed to link two

separate gate operators together as a Master/Slave pair. The Master/Slave

configuration is enabled by connecting two gate operators with simple,

unshielded twisted-pair wire (Max.100 ft.). All entrapment sensors, switch

inputs, receiver controls, and outputs must be wired to the gate operator

designated as the “Master”. The following procedure outlines the process for

configuring the Master/Slave pair.

Perform the “Learn” process to configure open and close limits with the gate

for each operator. See the “Programming Quick Start” procedures in this

manual for a description of the gate learning process.

On the Master operator, select Function -> Adv. Settings -> Remote Mst. Slv.

Then select On -> Master. The red LED associated with the Master/Slave

connector will illuminate.