1.

Test system characterization—Characterize the amplitude imbalance of the output ports

on your power splitter. The results of this step are used as a correction in the flatness and

bandwidth verification procedure.

2.

Verification—Verify the existing operation of the device. This step confirms whether the

device is operating within the published specification prior to adjustment.

3.

Adjustment—Perform an external adjustment of the calibration constants of the device.

The adjustment procedure automatically stores the calibration date and temperature on

the EEPROM to allow traceability.

4.

Re-verification—Repeat the Verification procedure to ensure that the device is operating

within the published specifications after adjustment.

Refer to the following sections to complete each procedure.

Test System Characterization

The following procedures characterize the test equipment used during verification.

Caution

The connectors on the device under test (DUT) and test equipment are

fragile. Perform the steps in these procedures with great care to prevent damaging

any DUTs or test equipment.

Zeroing the Power Sensor

1.

Ensure that the power sensor is not connected to any signals.

2.

Zero the power sensor using the built-in function, according to the power sensor

documentation.

Characterizing Power Splitter Amplitude Imbalance

This procedure characterizes the amplitude imbalance of the two output ports of the power

splitter over a range of frequencies.

The results of the characterization are later used as a correction in the

Verifying Flatness and

Bandwidth

procedure.

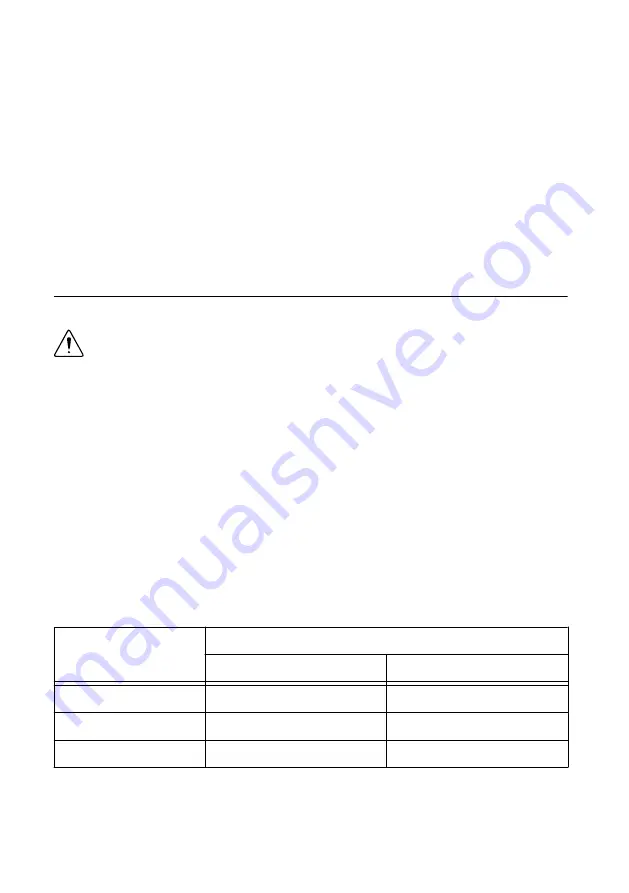

Table 2.

Power Splitter Characterization

Configuration

Test Point

Frequency (MHz)

Amplitude (dBm)

1

0.05

-0.5

2

50.1

-0.5

3

100.1

-0.5

1.

Connect an SMA (f)-to-N (f) adapter to the power sensor. Refer to this assembly as the

power sensor

.

2.

Zero the power sensor as described in the

Zeroing the Power Sensor

section.

NI PXIe-5170R Calibration Procedure

|

© National Instruments

|

7