20

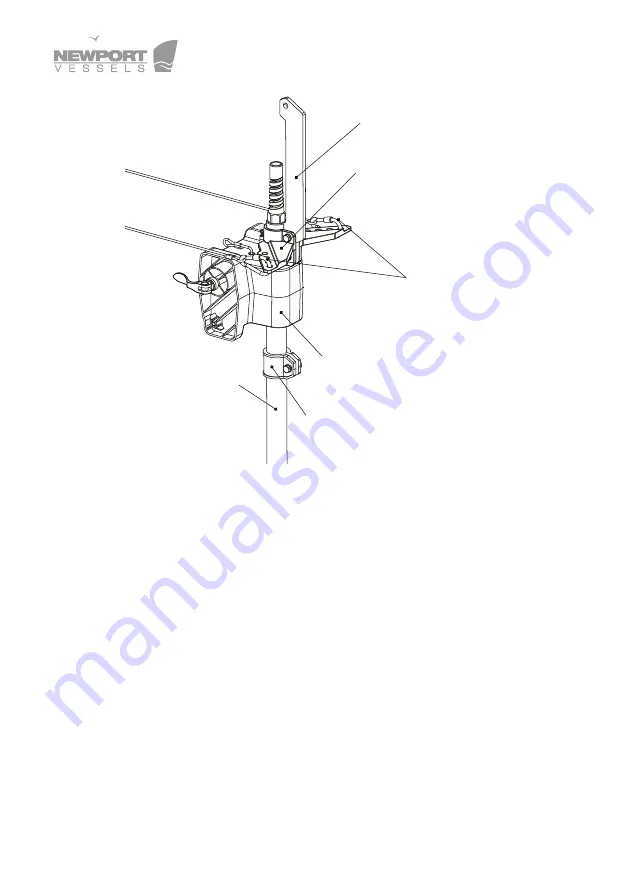

3. Slide the preassembled clamping ring onto the motor shaft.

4. Insert the motor shaft into the motor supporting drum with the

clamping ring below the drum, as shown.

5. Slide the preassembled steering triangle onto the motor shaft

above the drum, as shown.

6. Make sure the steering triangle is aligned with the direction of the

motor. If the triangle is an arrow, it should point towards the front

of the boat, while the propeller should face back.

7. Tighten the screws on the clamping ring and the steering triangle.

In this setup, the steering triangle determines the depth of the motor.

Make sure the propeller can be at least 2 inches (5 cm) below the

water surface.

Motor supporting drum

Clamping ring

Motor shaft

Steering triangle

Swing arm

Direction cords at the top