15

XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY, SAF, and logos are trademarks of SAF-

HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Torque Specifications

11. Torque Specifications

NOTE:

Torque specifications listed in this section

are with clean

lubricated/coated threads, supplied by SAF-HOLLAND.

IMPORTANT:

The use of special lubricants with friction

modifiers, such as Anti-Seize or Never-Seez

®

,

without written approval from SAF-HOLLAND

Engineering, will void warranty and could

lead to over torquing of fasteners or other

component issues.

General Information

The torque specifications listed throughout the manual are

applied to the lock nut and NOT the bolt.

IMPORTANT:

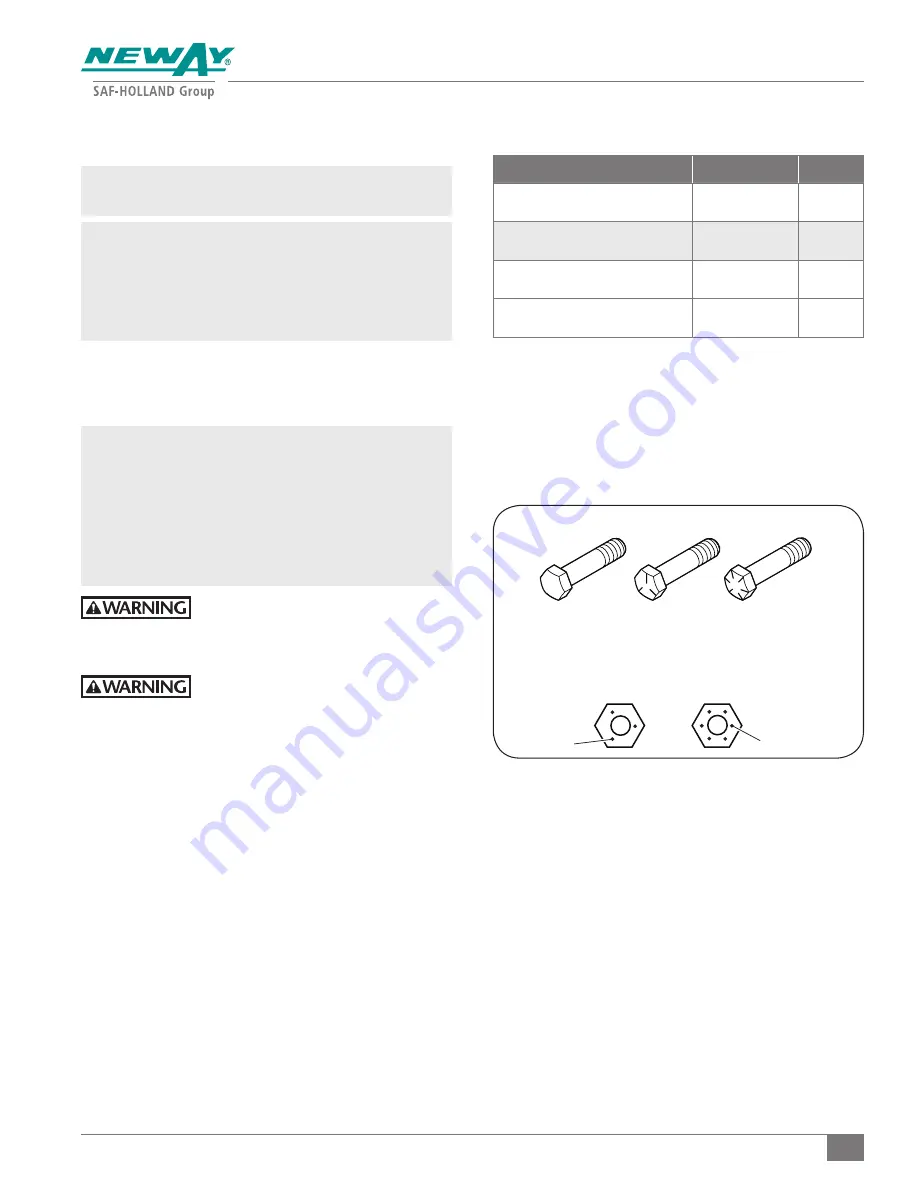

Most of the fasteners used in this suspension

are Grade 8 bolts and Grade C lock nuts.

These fasteners have the strength and

hardness properties required for their

particular function. They MUST be replaced

with fasteners of the same grade, size and

form as the original in order to prevent

failure

(Figure 10)

.

Failure to use the proper fasteners when

servicing the suspension could cause

component failure which, if NOT avoided,

could result in death or serious injury.

Failure to properly torque all fasteners

will result in component failure which,

if NOT avoided, could result in death or

serious injury.

All fasteners MUST be re-torqued after the first 100 hours

of service or 5,000 miles (8,000 km).

Refer to vehicle OEM for torque specifications for vehicle

frame fastener hardware.

COMPONENT

TORQUE RANGE

SIZE

Clevis Pin Assembly

18-24 ft-lb

24-33 N•m

5/16"-18

Chamber Bracket

37-50 ft-lb

50-68 N•m

1/2"-13

LSZ13 Pivot Connections

200-250

ft-lb

271-339 N•m

3/4"-10

LSZ20 Pivot Connections

330-370

ft-lb

447-502 N•m

7/8"-14

Table 1

GRADE 1 OR 2

BOLT GRADE MARKINGS

LOCK NUT GRADE MARKINGS

3 DOTS

LOCK NUT

GRADE B

LOCK NUT

GRADE C

6 DOTS

GRADE 5

GRADE 8

Figure 10