INTRODUCTION

Safety rules - Ecology and the environment

Soil, air, and water are vital factors of agriculture and life in general. When legislation does not yet rule the treatment

of some of the substances required by advanced technology, sound judgment should govern the use and disposal of

products of a chemical and petrochemical nature.

NOTE:

The following are recommendations that may be of assistance:

• Become acquainted with and ensure that you understand the relative legislation applicable to your country.

• Where no legislation exists, obtain information from suppliers of oils, filters, batteries, fuels, antifreeze, cleaning

agents, etc., with regard to their effect on man and nature and how to safely store, use, and dispose of these

substances.

• Agricultural consultants will, in many cases, be able to help you as well.

Helpful hints

• Avoid filling tanks using cans or inappropriate pressurized fuel delivery systems that may cause considerable

spillage.

• In general, avoid skin contact with all fuels, oils, acids, solvents, etc. Most of them contain substances that may be

harmful to your health.

• Modern oils contain additives. Do not burn contaminated fuels and or waste oils in ordinary heating systems.

• Avoid spillage when draining off used engine coolant mixtures, engine, gearbox and hydraulic oils, brake fluids, etc.

Do not mix drained brake fluids or fuels with lubricants. Store them safely until they can be disposed of in a proper

way to comply with local legislation and available resources.

• Do not allow coolant mixtures to get into the soil Collect and dispose of coolant mixtures properly.

• Do not open the air-conditioning system yourself. It contains gases that should not be released into the atmosphere.

Your NEW HOLLAND dealer or air conditioning specialist has a special extractor for this purpose and will have to

recharge the system properly.

• Repair any leaks or defects in the engine cooling or hydraulic system immediately.

• Do not increase the pressure in a pressurized circuit as this may lead to a component failure.

• Protect hoses during welding as penetrating weld splatter may burn a hole or weaken them, allowing the loss of

oils, coolant, etc.

47648338 18/06/2014

33

Summary of Contents for P2080

Page 4: ...47648338 18 06 2014 Find manuals at https best manuals com ...

Page 5: ...INTRODUCTION 47648338 18 06 2014 1 Find manuals at https best manuals com ...

Page 22: ...INTRODUCTION 15 2 m 50 ft and 18 3 m 60 ft drills SAIL13SE00490FA 19 47648338 18 06 2014 18 ...

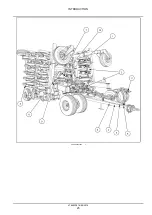

Page 29: ...INTRODUCTION SAIL14SE00089GA 1 47648338 18 06 2014 25 ...

Page 41: ...This as a preview PDF file from best manuals com Download full PDF manual at best manuals com ...