16

18

Operator's Manual

storage & maintenance

specific maintenance:

ENGINE: The engine instructions that accompany your unit detail specific

procedures for maintenance of the engine. Following the engine

manufacturer’s recommendations will extend engine work life.

PUMP:

The pump oil must be changed after the first 25 hours of operation.

Once the initial oil change has been completed, it is recommended

the oil be changed every 3 months or 250 hour intervals. If oil

appears dirty or milky, changes may be required at a greater

frequency. Use the following pump oil and fill only to the center of

the oil sight glass. DO NOT OVERFILL!

NOZZLES: Water flow through the spray nozzle will erode the orifice, making

it larger, resulting in a pressure loss. Nozzles should be replaced

whenever pressure is less than 85% of the maximum. The frequency

of replacement will depend upon such variables as mineral content

in the water and number of hours the nozzle is used.

QUICK COUPLERS: There is an o-ring seal inside the female quick coupler. This

o-ring will deteriorate or, if the unit is allowed to pump without

the high pressure hose or nozzle attached, the o-ring may be blown

out occasionally. Simply insert a replacement o-ring to correct the

leak. (Additional o-rings can be purchased from your dealer.)

BURNER AIR ADJUSTMENT: The air shutter has been factory preset for

proper operation between sea level and 2000 feet elevation at

standard conditions (60°F ambient water and air temperatures). To

assure maximum combustion efficiency at colder temperatures and

higher altitudes, it will be necessary to adjust the air supply to the

combustion chamber. A smoke spot test is recommended during

any air shutter adjustment. This will aid in maximizing the burner

efficiency and avoid inefficient operation and excessive sooting of

the combustion chamber.

1. The machine must be running and the burner ON.

2. Take a smoke spot test to determine if more or less air is

required for proper combustion.

a. If the test is greater than a #3 smoke, turn the shutter

arm

counterclockwise

to increase the air flow into the

combustion chamber.

b. If the test is yellowish in color, turn the shutter arm

clockwise

to decrease the air flow into the combustion

chamber.

3. Hold onto the air shutter adjusting arm and loosen the locking

nut.

Move the shutter in 1/8" increments and retighten the

locking nut after each 1/8" movement.

4. Trigger the gun on and off slowly to make sure there is proper

ignition. Slight or no puffing on the ignition, and a smoke spot

test of less than #3 smoke is good.

5. Repeat steps 2 and 3 until step 4 is attained.

LEAKS:

Promptly eliminate any leaks found in the pumping system by

removing suspect parts, applying thread sealant to the threads

and reinstalling.

NOTE: If using teflon tape, be certain no tape gets inside any plumbing to

prevent the possibility of a plugged spray nozzle.

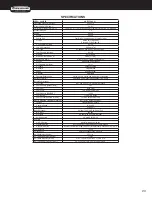

Model #

Pump Oil

HSP

SAE30W non-detergent

Summary of Contents for MN2765HAHW

Page 1: ...operation manual MN2765HAHW MODEL NUMBER...

Page 8: ...8 8 Operator s Manual features 2500 psi HSP 2500 FEATURES 122208 CH...

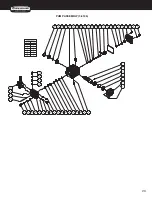

Page 24: ...24 4 Copyright 2011 EX 9836 101011 FLOW CHART EMF SYSTEM HSP115 080499 BAR HSP046 072996 BAR...

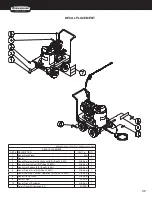

Page 29: ...29 12 yright 2011 EX 9836 101011 PUMP ASSEMBLY 3 0146...

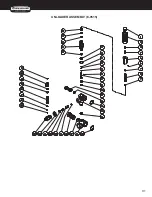

Page 31: ...31 14 EX 983 UNLOADER ASSEMBLY 8 0515...

Page 40: ...40 26 yright 2011 EX 9836 1010 WIRING SCHEMATIC WIRING DIAGRAM...