10

Note: Do not immerse Spray Gun Body in solvent. Do not allow solvent to enter the air inlet.

6. Remove Nozzle by hand and soak it in solvent until it is clean. Use brush to remove any

paint.

Note: To prevent damage to the passages, do not use metal objects to clean the Nozzle.

7. Wipe down Spray Gun Body with a clean cloth and solvent.

8. Make sure all parts are free from residual paint.

9. If switching from oil-based to latex paint, after cleaning

with solvent, clean all parts with warm soapy water.

10. Rinse with warm water, then thoroughly blow dry all

parts with compressed air.

11. Reassemble Spray Gun.

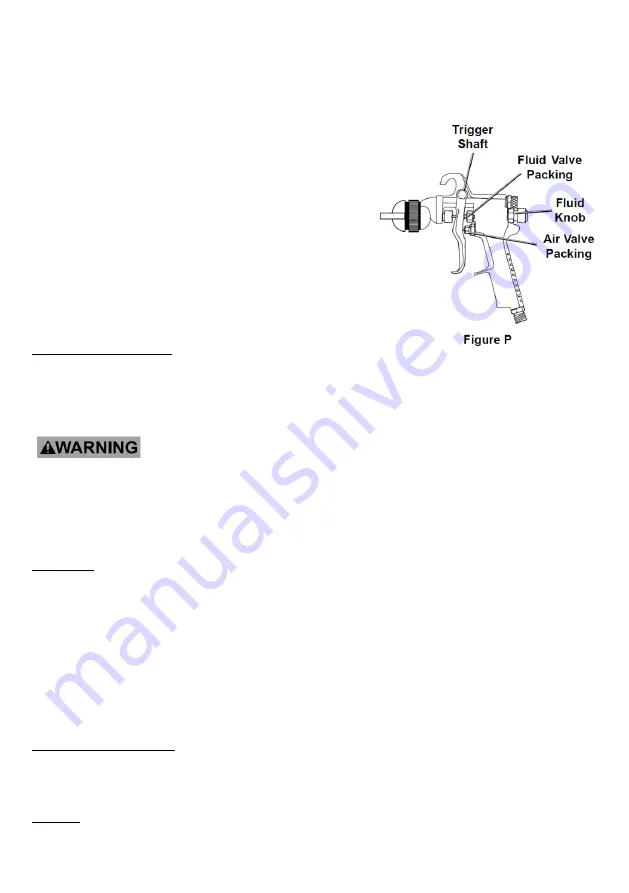

12. Use spray gun lubricant (sold separately) on

EXTERNAL moving parts. (See Figure P)

NOTICE:

Do not use any kind of lubricant in air supply

or air inlet. The lubricant will mix with paint, causing poor

results.

Spent Solvent Disposal

After cleaning, dispose of spent solvent according to the solvent manufacturer’s

directions and local hazardous waste standards.

5. MAINTENANCE

TO PREVENT SERIOUS INJURY:

Detach the air supply and safely discharge any residual air

pressure in the tool

before performing any inspection, maintenance, or cleaning procedures.

TO PREVENT SERIOUS INJURY FROM TOOL FAILURE:

Do not use damaged equipment.

If abnormal noise, vibration, or leaking air occurs, have the problem corrected before further

use.

Inspection

Note: These procedures are in addition to the regular checks and maintenance

explained as part of the regular operation of the air-operated tool.

BEFORE EACH USE,

inspect the general condition of the tool. Check for:

• loose screws,

• misalignment or binding of moving parts,

• clogged nozzle or fluid tip,

• damaged air supply hose,

• cracked or broken parts, and any other condition that may affect its safe operation.

Air Supply Maintenance

Every day, perform maintenance on the air supply according to the component manufacturers’

instructions.

Storage

Store in a dry, secure area out of reach of children.