Press On/Off switch push forward to lock position, then release the On/Off switch.

The angle grinder will continue to operate until the on/off switch is released.

To release the on/off switch, just press switch again. It will return to original

position

CAUTION!

Always carry out a test run before starting work and after every tool

change! Always ensure that the tools are in good condition, correctly mounted

and able to turn freely. The trial run should be at last 30 sec.

WARNING

Vibrating discs must be replaced immediately.

Please always keep other persons and combustible material from work area.

Please always make sure work with guard and disc in position before start the

machine.

Mounting disc

The mounting hole of disc must fit with the mounting flange. Do not use reducers

or adapters.

The direction-of-rotation arrow on disc and machine (see direction-of-rotation

arrow on the machine head) should be same.

CAUTION!

Never use discs whose diameter is larger than that indicated.

The maximum rotation speed of disc must be greater than the idling speed of the

machine.

CAUTION!

Never use the grinding disk for cutting

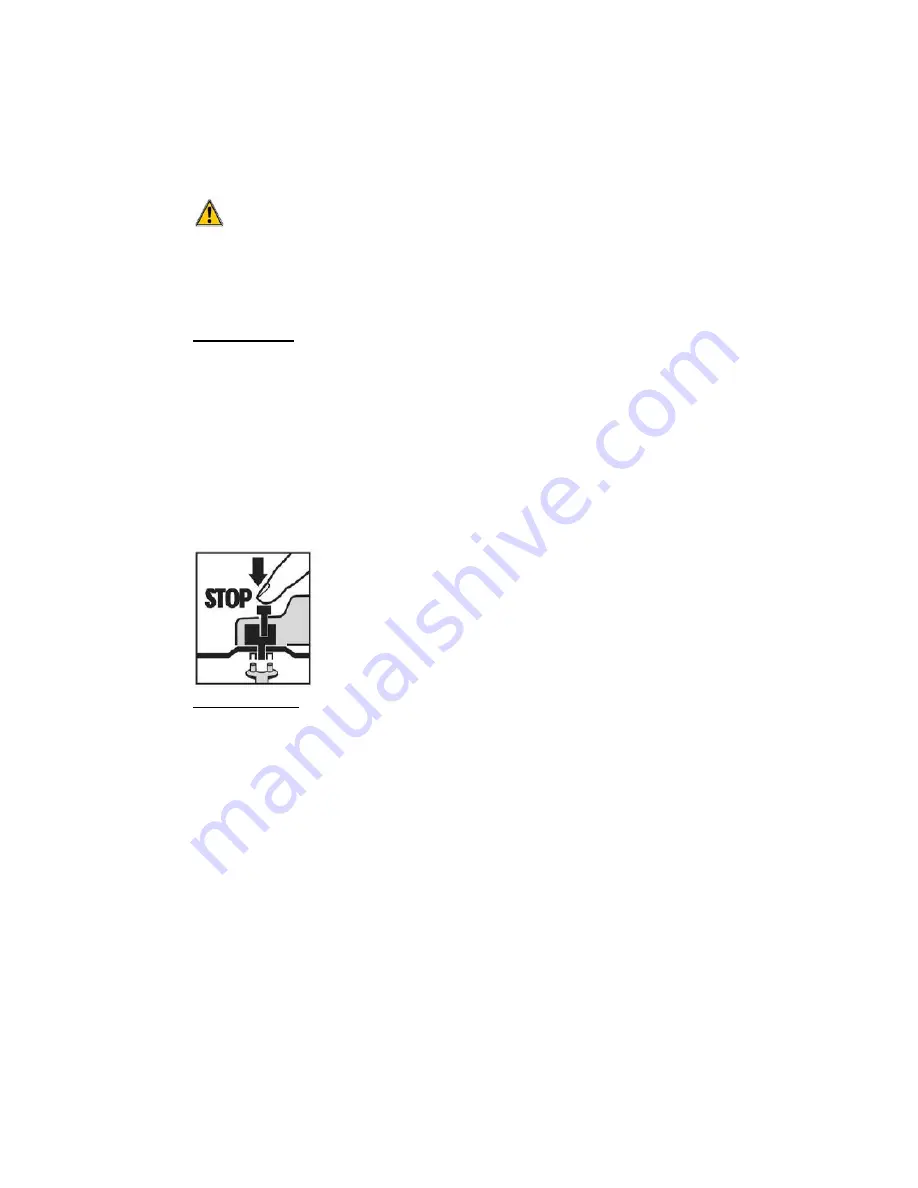

To assembly the disc, press the spindle-lock button in deep

and hold it in this position continuously. If necessary, turn the

spindle slightly with the free hand until it locks into position.

And then put the disc between two flanges and then tighten

the outer flange with the spanner provided.

Removing disc

To remove the disc, press the spindle-lock button in deep and hold it in this

position continuously. If necessary, turn the spindle slightly with the free hand until

it locks into position.

Loose the flange with the spanner provided and then removes the disc from

spindle.