2013-04-15

SERVICE FORM

CUSTOMER:

_________________________________________________________________________________________

VACUUMER TYPE/MODEL:

___________________________________________________________________________

SERVICE DATE ___________________ SERVICED BY: ______________________________________________________

OK

Reparied

Replaced

Replaced part number

1.0

CONTROL WITHOUT RUNNING, OUTSIDE

1.1

Silencer

1.2

Compressed air hose

1.3

Container(s)

1.4

Trolley

1.5

Suction hose(s)

1.6

Preseparator/cyclone

1.7

Accessories

1.8

Other items, specify

2.0

CONTROL WITHOUT RUNNING, INSIDE

2.1

Gasket(s)

2.2

Lid, vacuum head

2.3

Container(s)

2.4

Filter(s)

2.5

Dustbag

2.6

Float ball

2.7

Other items, specify

3.0

CONTROL RUNNING, (TOP COVER

INSTALLED)

3.1

Start/stop switch function

3.2

Vacuum

3.3.

Noise level

4.0

CONTROL RUNNING, (TOP COVER

DISMANTLED)

4.1

Rotation motors

4.2

Thermoswitch function

5.0

CONTROL WITHOUT RUNNING, (TOP AND

SECONDARY COVERS DISMANTLED)

5.1

Electric cable connections

5.2

Carbon brushes

5.3

Commutator wear

5.4

Motor wear

5.5

Radio disturbance compression card

Summary of Contents for 42451002

Page 17: ...17 02 2010 NEL2 NEL3 NEL3R NEL2R NEL3RT NEL3T MAX 40 C S2 ì ìí ð ëì ïðð ...

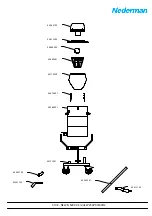

Page 20: ...43908004 43903041 43908014 43908010 S235JR St37 2 1 2 3 System 50 200 ...

Page 21: ... ...

Page 23: ...43999015 43907008 43907007 43731001 ...

Page 24: ...Material C F PE PVC PUR 43 8 12 103 ...

Page 26: ...18 06 2008 Addendum to Manual ...

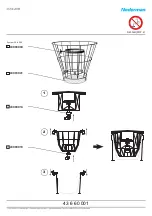

Page 28: ...1 4 2 3 1 2 3 1 2 ...

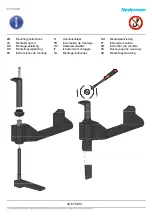

Page 29: ...1 2 3 4 10mm 22mm 5 6 7 8 9 A B C D 10 11 1 x 2 x 3 x ...

Page 31: ......

Page 32: ...www nederman com ...