9

© by NECTA VENDING SOLUTIONS SpA

0404 211 - 02

Chapter 2

INSTALLATION

The machine installation and the following mainte-

nance operations should be carried out by qualified

personnel only, who are trained in the correct use of

the machine and are aware of the specific risks of such

operations.

The machine is not suitable for outdoor installation, it

must be installed in a dry room where the temperature

remains between 5°C and 32°C.

It cannot be positioned where water jets are used for

cleaning (e.g. in large kitchens, etc.).

The machine should be positioned with a maximum

inclination of 2°.

The relative humidity must not exceed 65%.

UNPACKING THE VENDING MACHINE

After removing the packing, ensure that the machine is

intact.

If the vending machine is found to be damaged, immedi-

ately inform the carrier and do not use the machine.

No packing elements (i.e. plastic bags, polystyrene

foam, nails, etc.) should be left within the reach of

children, as they are potentially dangerous.

Packing materials must be disposed of in authorised

containers and the recyclable ones must be recovered by

qualified companies.

If the vending machine had been laid down during

transport, allow at least one hour before connecting it

to the mains.

INSTALLING THE PAYMENT SYSTEM

The machine is sold without payment system, there-

fore the installer of such a system has sole responsi-

bility for any damage to the machine or to things and

persons caused by incorrect installation.

Install the coin mechanism paying attention, according to

the type used, to:

- choose the most suitable securing holes;

- loosen the fastening screw and adjust the coin slot

chute according to the coin mechanism opening;

- loosen the fastening screws and adjust the selector

opening lever;

- to aid installation the coin mechanism support plate

can be lifted and rotated.

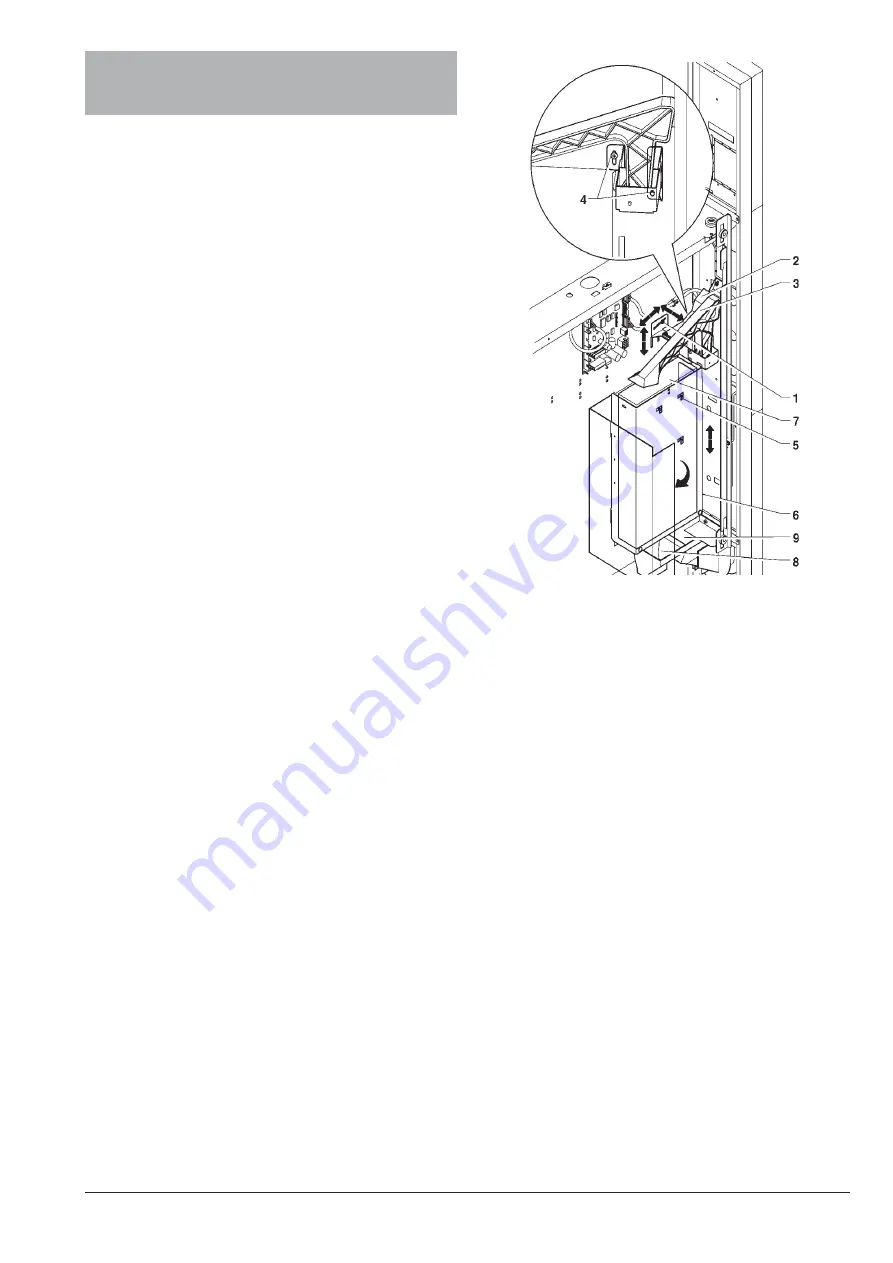

Fig. 12

1 - Coin chute fastening screw

2 - Coin chute

3 - Selector opening cam

4 - Selector lever fastening screw

5 - Coin mechanism securing holes

6 - Coin mechanism compartment door

7 - Coin mechanism

8 - Coin slot chute

9 - Coin return chute

Summary of Contents for Sfera

Page 1: ...INSTALLATION USE AND MAINTENANCE MANUAL UK English Sfera DOC NO H 211U 02 EDITION 2 2004 04...

Page 2: ......

Page 4: ......

Page 62: ...sx38500...

Page 63: ...Sfera...

Page 64: ...sx38601...

Page 65: ...Sfera...

Page 66: ...by NECTA VENDING SOLUTIONS SpA NOTE...

Page 68: ......