12

|

ni.com

|

Getting Started NI SMD-7613/7614/7615/7616 Stepper Drives

•

Position

— Specify the target position, in the axis will be driven toward.

•

Velocity

— Specific the maximum velocity of the move in steps/s.

•

Acceleration

— Specify the maximum rate of acceleration when starting the move, in

Units/s

2

.

•

Deceleration

— Specify the maximum rate of deceleration when stopping the move, in

Units/s

2

.

When all the settings are configured, run the VI, and click the

Start Move

button. The motor

should turn according to the configured move. Click the

Stop Move

button to stop the motor,

and the

Stop VI

when you are finished with the project.

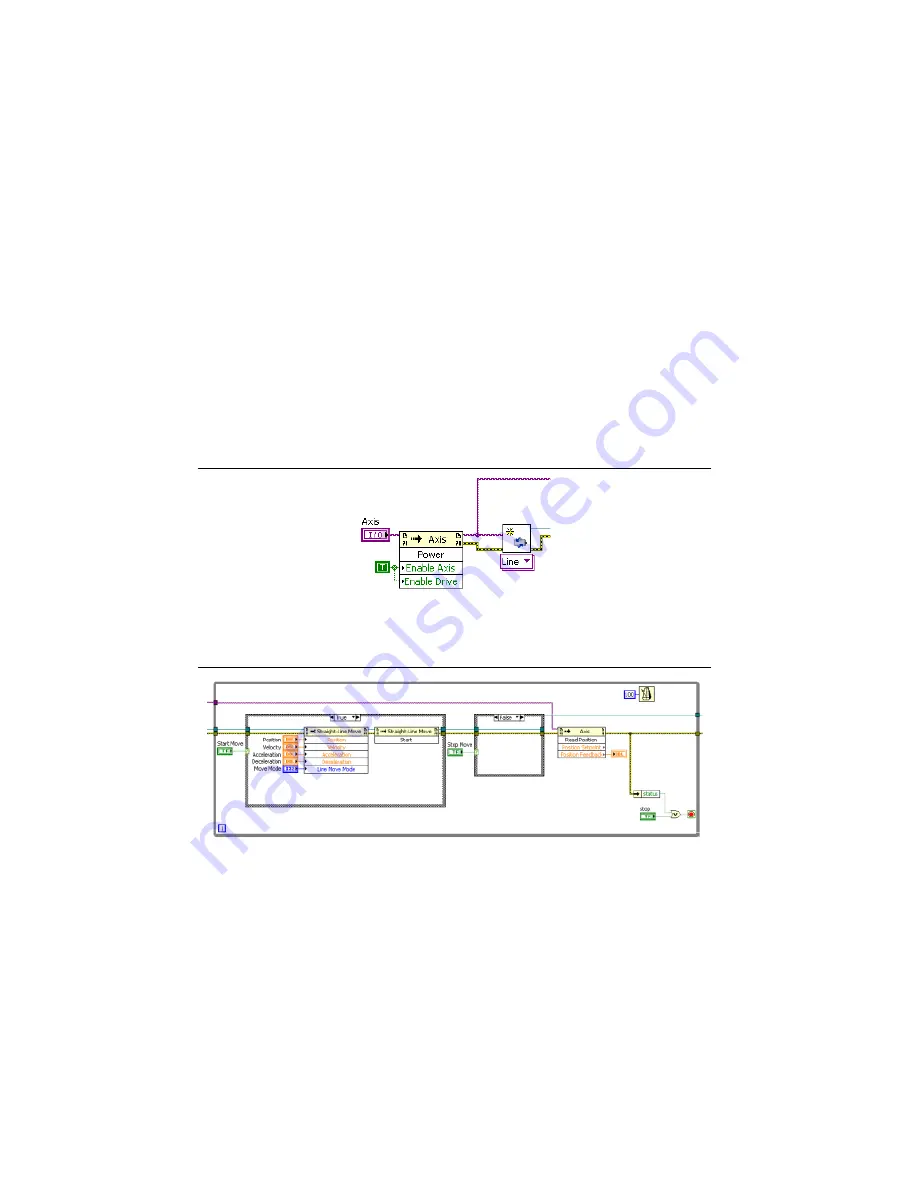

Understanding the Example

The example VI begins by creating a motion resource and using an invoke node to enable the

drive.

Figure 9.

Creating a Motion Resource

When the move is started, all of the configured parameters are written with a property node. The

position feedback is read with an invoke node and displayed.

Figure 10.

Applying the Move Parameters