65

MAXIMUM ANGLES OF

INCLINATION DURING

OPERATION

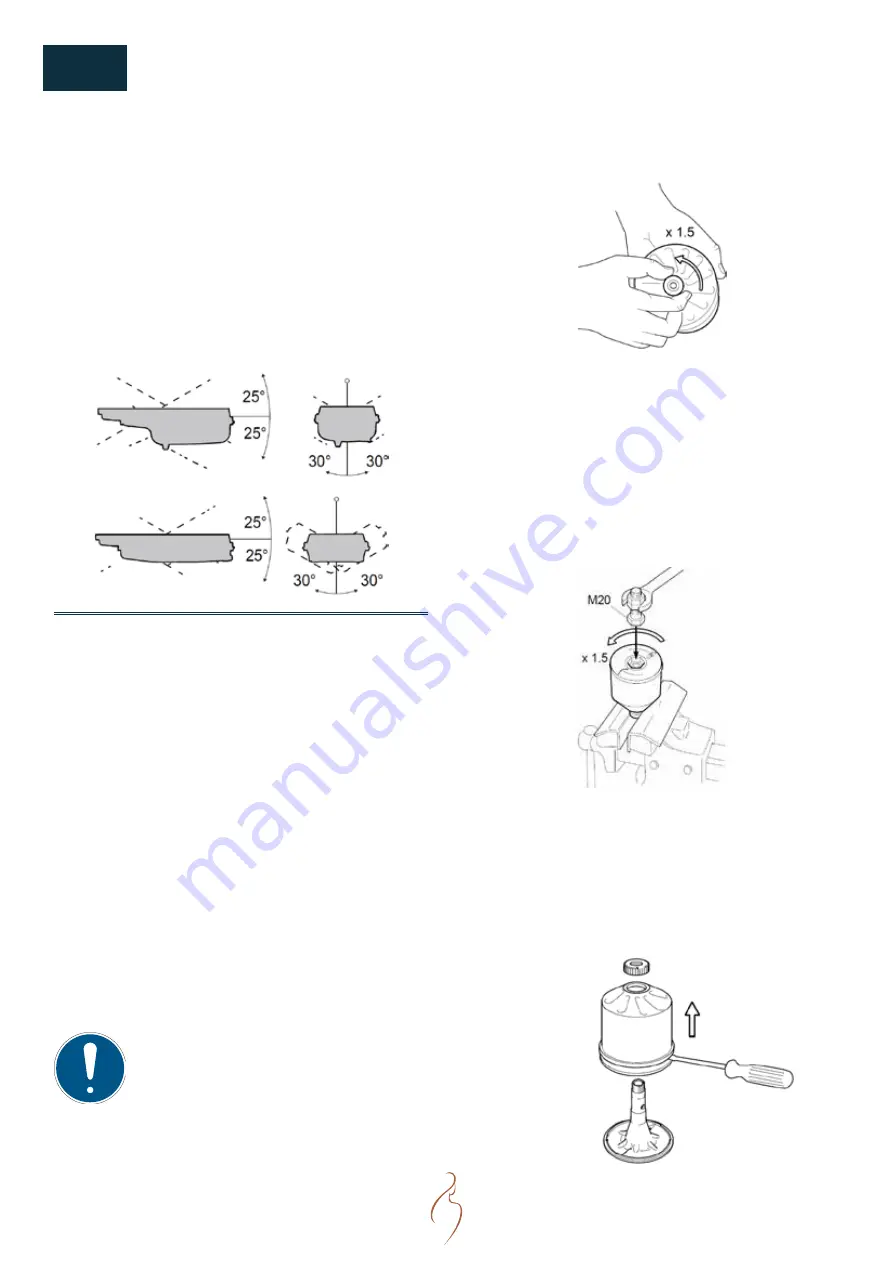

Maximum permissible angles of inclination during oper-

ation vary, depending on the type of oil sump. See illus-

tration below:

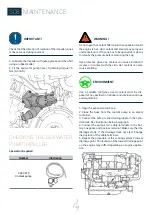

CLEANING THE

CENTRIFUGAL OIL CLEANER

When the centrifugal oil cleaner is cleaned, there should

be some dirt deposits on the paper in the rotor cover. If

the paper is clean, the equipment is not working as it

should. If this is the case, investigate the cause of this.

Renew the paper more frequently if the dirt deposits are

thicker than 28 mm (1.1 inches) during a scheduled oil

change.

1. Clean the cover.

2. Unscrew the nut securing the outer cover.

3. Let the oil run out from the rotor.

4. Lift out the rotor. Wipe off the outside.

5. Loosen the rotor nut and unscrew it about 1.5 turns.

NOTE !

Take care not to damage the rotor shaft.

S08

MAINTENANCE

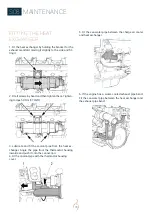

6. If the rotor nut is jammed: Turn the rotor upside down

and fasten the rotor nut in a vice.

7. Use protective jaws so as not to damage the grooves

of the rotor nut.

8. Turn the rotor 1.5 turns anti-clockwise by hand.

9. If this does not work: Screw two nuts together with an

M20 screw.

10. Position the screw head at the bottom of the rotor.

11. Position a ring spanner on the lower nut and turn the

rotor 1.5 turns anti-clockwise. See illustration below:

12. Remove the rotor cover by holding the rotor in both

hands and tapping the rotor nut against the table. Never

strike the rotor directly as this may damage its bearings.

13. Remove the strainer from the rotor cover. If the

strainer is stuck, insert a screwdriver between the rotor

cover and strainer and carefully prise them apart.

Summary of Contents for N16.1000 CR3

Page 2: ......

Page 4: ......

Page 34: ...34 S05 COMPONENTS ENGINE VIEWS N16 CR3...

Page 35: ...35 NOTES...

Page 48: ...48 S06 INSTRUMENTATION SYSTEM LAYOUT INCLUDING OPTIONS...

Page 118: ......